Rubber Upper Flex Resistance Tester China Supplier

Upper Material Flexing Resistance Tester is designed to simulate squeezing, stretching, creasing and bending applied to the different positions of upper of shoe worn on the feet while walking to evaluate the quality of footwear material. It is a commondly used footwear testing equipment.

Test Principle

Double creases similar to those formed in the upper of a shoe during wear are generated repeatedly in specimens of upper material by means of a this flexing tester until cracking of the upper material is observed or until the test pieces survive a given number of flexure cycles.

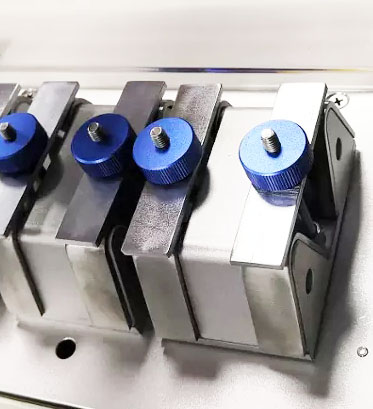

This apparatus has an adjustable stationary clamp 25 mm in width for holding one end of the specimen in a fixed position, and a similar reciprocating grip for clamping the other end of the specimen.

The axis of the movable part is in the same straight line as that of the stationary part so that the reciprocating motion is in the same plane as the centreline between the grips. The clamps are 28.5 ± 2.5 mm apart in the open position and 9.5 mm ± 1.0 mm apart in the closed position.

It is equipped with a cam that actuates the reciprocating part. The movable part is driven by a constant-speed motor at the frequency of 340 flexes / min to 400 flexes / min.

The specimens are arranged in 2 equal groups so that one group is being bent while the other is being straightened, thus reducing the vibration in the machine. The clamps can fix the specimen firmly and enable individual adjustments to be made to each specimen.

Test Standards

- ISO 5423-5.2 Resistance to flexing of boot upper Moulded plastics footwear – lined or unlined polyurethane boots for general industrial use-specification

- ISO 20344-6.5.2 Determination of upper flexing resistance Personal protective equipment-test methods for footwear

- ISO 4643 Resistance to flexing of boot upper Moulded plastics footwear – lined or unlined polyurethane boots for general industrial use-specification

- AS/NZS 2210.2-6.5.2 Resistance to flexing of boot upper Moulded plastics footwear – lined or unlined polyurethane boots for general industrial use-specification

- GB/T 20991-6.5.2 Resistance to flexing of boot upper Moulded plastics footwear – lined or unlined polyurethane boots for general industrial use-specification

- GB/T20265-4.1 vamp flexing resistance, Moulded plastics industrial boots with chemical resistance

- EN ISO 22288 Physical and mechanical tests-determination of flex resistance by the vamp flex method

- SATRA TM25 Vamp flex test-resistance to creasing and cracking

Main Technical Parameters

| Model | AT-L9005 |

| Number of Grips | 12 pcs |

| Specimen Size | 64 mm × 64 mm |

| V-shaped Angle | (40 ± 1)° |

| Radius of V-Clamp | (6.4 ± 0.5) mm |

| Distance Between the Clamps in the Open Position | (28.5 ± 2.5) mm |

| Distance Between the Clamps in the Closed Position | (9.5 ± 1.0) mm |

| Travel of Moving Clamps | (19 ± 1.5) mm |

| Movement speed (frequency) | (300 ± 30) cpm |

| Counter | LCD 999,999 |

| Dimension | 55 cm × 35 cm × 30 cm |

| Weight | 64 kg |

| Power | 1 phase, AC 220V or specified |

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.