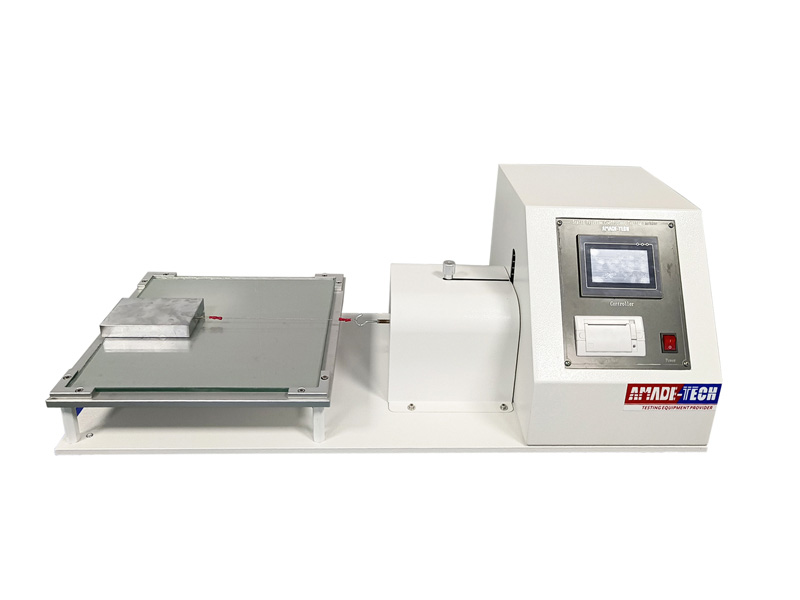

Outsole Rigidity Tester China Manufacturer and Supplier

Outsole Rigidity Tester is also called the outsole bending stiffness tester. It is used to determine the rigidity of outsoles by measuring the bending angle required to achieve an intended force or the bending force required to achieve the desired angle.

This rigidity tester is an indispensable auxiliary device when conducting outsole flex resistance tests using the Outsole Flexing Tester or the Bennewart Flex Tester, as it can assess the sample rigidity to decide whether the sample is qualified to acquire a flexing resistance test. For example, ISO 17702 stipulates that you must preset the bending angle to 45° before the test. If the bending force required to reach this angle is greater than 30 N, the sample can’t be subjected to the flexing test.

Test Principle

The forepart of the sample is clamped to the base plate in such a way that the flexing line AC is aligned with the hinge axis of the base plate. A pulley is able to drive the hinged plate to apply a force to flex the sample at a specified speed until a predetermined condition is reached. Generally, you are required to measure the bending angle required when conditioning a fixed load of 30 N or measure the bending force required when conditioning a fixed angle of 45°.

Test Standards

GB/T 20991 section 8.4.1

ISO 20344-2011 section 8.4.1

AS/NZS 2210.2 section 8.4.1

ISO 17707 section 4.2, etc.

Core Technical Parameters

| Model | AT-F3044 |

| Capacity | 500N |

| Load resolution | 1/10000 |

| Angle resolution | 0.1° |

| Bending speed | 100 mm/min (adjustable) |

| Test load | 30N |

| Measurement methods | Measure force / bending angle |

| Power supply | 1 Phase AC 220V or 110 V |

Outsole Rigidity Tester Features

- Made of superior metal materials to ensure rigidity and durability of the whole machine.

- Support 2 test methods: Measuring the flexing angle/flexing force.

- Equipped with a load cell and an encoder to facilitate test automation.

- Fitted with a high-definition touch screen for parameter settings and data monitoring.

- Allows to preset test conditions flexibly.

- User-friendly and easy to maintain.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.