IPX 3/4/4K Waterproof Test Chamber / Set-up China Manufacturer and Supplier

IPX3/IPX4 Water Spraying & Splashing Test Equipment is used to determine the protection of the sample enclosure against spraying water and splashing water. It is a 2-in-1 water ingress protection test equipment to perform two different levels of waterproof tests. You only require replacing corresponding oscillating tubes with each other to achieve alternate testing of IPX3 and IPX4. IPX4K testing is carried out with additional pressure on the basis of the test conditions of IPX4.

The oscillating tube made of stainless steel is a semi-circular hollow pipe distributed with holes at the specified density and size to point to the center of the circle. Swivel tubes of different radii are available to cater to various samples. The tubes for IPX3 testing can spray water over the sample at an angle up to 60° on either side of the vertical plane, and the tubes for IPX4 testing can splash water over the sample from any direction. All spraying actions of the machine are performed automatically at a specified rate under control. The IP4K tubes have high requirements for the water pressure and water flow rate based on the IP4 test conditions to allow the sample to suffer from more severe splashing. The maximum test distance required by the 3 test items is 200 mm.

Water spray testing in chamber

IPX3 / IPX4 test demo video

IPX4K test demo video

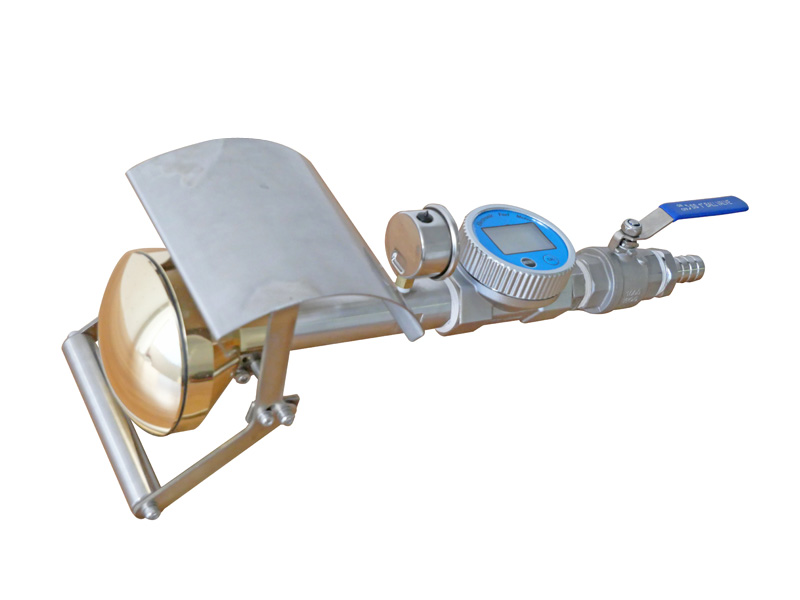

Open-type water spray tester

In addition to the chamber-type rain test device, AmadeTech also supplies IPX3/4/4K open-type spraying and splashing test equipment. Usually, the maximum radius of the oscillating tubes of the box-type rain test equipment is 800 mm, which is fit for small and medium-sized products. If you select an open-type machine, the radius of the oscillating tube is allowed to be extended up to 1600 mm.

The open type is free from a confined test space, which is suitable for specimens of large dimensions. Unlike the box-type test chamber allowing you to place it anywhere in the laboratory, the open-type test equipment has severe requirements for the test site. You have to pick a completely waterproof room as the place to conduct the test.

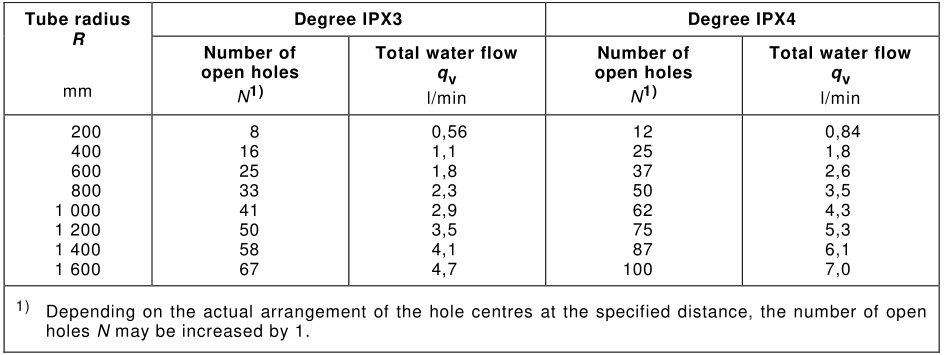

You are available to customize the specifications of the equipment to accommodate your specimens. The radius of the swivel tube has 8 specifications: R200, R400, R600, R800, R1000, R1200, R1400, and R1600. If the radius of the tube is different, the corresponding number of openings and the total water flow will also be different.

If you want to perform more levels of IP waterproof testing but don’t want to buy a variety of equipment. AmadeTech can integrate the hardware required for different levels of waterproof testing from IPX1 to IPX6, and even IPX9 into the same chamber, which can greatly facilitate your testing. Welcome to contact us to learn more.

For certain types of irregular specimens, you may have difficulties in wetting all parts of the enclosure using the built-in oscillating tube. In such a case, the IPX3/4 hand-held spray nozzle is the ultimate solution.

It requires you to operate manually without limit of the spray angle, allowing spray on anywhere you want throughout the test.

Please click the right button to learn more.

A complete IP testing equipment based on IEC60529 and ISO 20653 is also available at AmadeTech. Please click HERE to learn more.

Conforming Test Standards

- IEC 60529

- ISO 20653

- DIN 40050-9

- IEC 60598-1

- IEC 60068-2-18

- IEC 60034-5

Main Technical Specifications

Model | AT-C1005B-200 | AT-C1005B-400 | AT-C1005B-600 | AT-C1005B1-600 | AT-C1005B1-800 | AT-C1005B1-1000 | AT-C1005B1-1200 | AT-C1005B1-1400 | AT-C1005B1-1600 | |||

Equipment type | Box-type with an enclosed chamber | Open-type | ||||||||||

Oscillating tube radius | R200 mm | R400 mm | R600 mm | R600 mm | R800 mm | R1000 mm | R1200 mm | R1400 mm | R1600 mm | |||

Turntable diameter | Dia. 200 mm | Dia. 400 mm | Dia. 600 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 800 mm | Dia. 800 mm | Dia. 1000 mm | |||

Overall dimensions | (W) 955 x (D) 700 x (H) 1450 mm | (W) 1350 x (D) 1120 x (H) 1770 mm | (W) 1750 x (D) 1550 x (H) 1950 mm | (W) 1950 x (D) 1250 x (H) 1550 mm | (W) 2450 x (D) 1650 x (H) 1950 mm | (W) 2850 x (D) 2050 x (H) 2350 mm | (W) 3200 x (D) 2450 x (H) 2700 mm | (W) 3580 x (D) 2850 x (H) 3100 mm | (W) 4000 x (D) 3250 x (H) 3530 mm | |||

Turntable height range | 150 ~ 250 mm adjustable | 350 ~ 600 mm adjustable | 550 ~ 1000 mm adjustable | 770 ~ 1200 mm adjustable | 1000 ~ 1400 mm adjustable | 1300 ~ 1700 mm adjustable | 1500 ~ 1900 mm adjustable | 1600 ~ 2000 mm adjustable | 1700 ~ 2100 mm adjustable | |||

Spacing of holes | 50 mm | |||||||||||

Number of spray holes | As per specific test requirements | |||||||||||

Hole diamter | Dia. 0.4 mm for IPX3/IPX4, and Dia. 0.8 for IPX4K | |||||||||||

Oscillating angle of tube | ± 60° for IPX3 / ± 180° for IPX4/4K | |||||||||||

Turntable loading capacity | Max. 50 kg or customized | |||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | |||||||||||

Control mode | PLC + 7-inch touch screen | |||||||||||

Feature | Allows energized samples during the test | |||||||||||

IPX3/4/4K Water Spraying Tester Features

Frequently Asked Questions (FAQs)

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.