Bally Leather Flexing Tester China Manufacturer

Bally Flexometer is also called the Bally leather flexing tester, which is intended to determine the wet or dry flex resistance of leather and finishes applied to leather when subjected to a given number of continuous flexes within a period of time.

This digital flexometer is applicable to all types of flexible leather less than 3 mm in thickness and is widely used in leather, shoemaking, luggage, furniture and other industries. It not only complies with the international standards of ISO 5402-1, IULTCS/ IUP20-1, but also meets the JIS, DIN, ASTM and other test standards.

Amade is capable of provide 4-station, 12-station and 24-station bally flexometers based on your testing requirements. If you need a machine to determine the flexing resistance of the upper leather, you may consider another Vamp Flexing machine.

4-station bally flexometer

12-station bally flexometer

Test Principle

One end of the 70 mm × 45 mm specimen is folded longitudinally in half with the grain surface facing outwards and clamped firmly in the upper moveable clamp. The free corners of the specimen are dragged outward and downward around the upper grip to enable the grain surfaces to be attached together. The surface to be tested is outward. The free end of the sample is clamped perpendicularly in the lower fixed clamp to ensure that the leather is just taut.

After the motor is started, the upper clamp moves back and forth at a specified angle of 22.5° ± 0.5° and speed of 100 ± 5 cycles per minute. The test piece is examined for damage after a specified number of flex cycles or at regular intervals during the reciprocation.

Main Specifications

| Model | AT-L9002 |

| Grips | 4 / 12 / 24 pcs optional |

| Specimen Size | 70 × 45 mm |

| Flexing Angle | 22.5° ± 0.5° |

| Flexing Frequency | 100 ± 5 cpm |

| Counter | Digital LCD, 0~999,999 |

| Dimension | 64 × 50 × 35 cm (W × D × H) |

| Weight | 78 kg |

| Power Supply | AC 220V, 50 Hz 1 phase / AC 110 V, 60 Hz (or specified) |

| Standard Accessories | Press knife (70 × 45 mm), special spanner, operation manual |

| Optional Accessories | Magnifier, desiccator, vacuum pump, distilled or deionized water, glass dishes, mandrel, metal clip, dtereomicroscope |

Test Standards

- BS-3144 Methods of sampling and physical testing of leather

- JIS-K6545 Testing method for flexing endurance of light leathers and their surface finishes

- ISO 5402-1 Leather-determination of flex resistance Part1: Flexometer method

- QB/T 2714-2005 Leather-Physical and mechanical tests-determination of flex resistance

- EN ISO 17694 Footwear-test methods for uppers and lining-flex resistance

- EN 13512 Footwear-Test methods for uppers and lining-flex resistance

- IULTCS/IUP 20-1 Leather-determination of flex resistance

- SATRA TM55 Flexing resistance of upper materials-bally flexometer

- EN 344-1 Safety protective and occupational footwear for professional use Part1 requirements and test methods

- ISO 20344 Personal protective equipment-test methods for footwear

- AS/NZS 2210.2 Occupational protective footwear test methods

- ISO 32100 Rubber or plastics coated fabrics physical and mechanical tests-determination of flex resistance by the flexometer method

- DIN 53351 Testing of artificial leather and similar sheet materials-permanent folding behavior (Flexometer method)

- GE-24 Adidas & Reebok footwear test standard Flexometer test or Flexometer test after 7days Hydrolysis

- ASTM D6182 Standard test method for flexibility and adhesion of finish on leather

- GB/T 20991 Personal protective equipment-test methods for footwear

Bally Flexing Tester Features

This leather flexometer’s design and manufacturing strictly follow various international standards.

The outer box of the machine is formed from hard steel plates. The surface is treated with electrostatic spraying and anti-corrosion, and the structure is solid and durable.

The clamps are made of stainless steel, and the specimens are easy to be mounted into the machine with the help of the butterfly nuts.

This leather testing machine is an LCD with an English interface, sensitive buttons, a convenient and humanized control system, and a durable and precision motor.

The control system has functions of memory and automatic stop. After you stop the flexing test from checking the change of the sample, you can click start to resume the test. If you set the number of flex to 20,000, you do not need to stand guard over the machine. When 20,000 times are reached, the machine will automatically stop. It allows you to handle other things in the test.

We offer models of 6-station, 12-station and 24-station for you to choose from. The routine is 12 stations. The advantage of the 24-station machine is that you don’t need to purchase two machines if you want to test 24 samples simultaneously. It is efficient and cost-saving.

Control Panel

Arrays of Clamps

Bending angle mark

How to Prepare the Leather Samples for the Bally Flex Test?

- Cut at least four pieces for the dry test and four pieces for the wet test by a press knife, sample size by 70 x 45 mm. (Sampling location: cut at least two test pieces with the long edge parallel to the backbone and two with the long edge perpendicular to the backbone).

- For dry flex testing, condition the samples at a temperature of 20℃ and relative humidity of 65%.

- For wet flex testing, place the samples in the glass dish, add sufficient distilled or deionized water, put the dish in the desiccator, and reduce the pressure to below 4 Kpa for 2 minutes. Restore to normal atmospheric pressure and repeat the pressure reduction twice. Remove the test piece, remove excess water using blotting paper, and then carry out the flexing test immediately.

What’s the Leather Flexing Test Procedure?

- Mount the half-folded sample in the movable clamp. Make sure that the backside of the leather faces outward, then drag the free corners of the specimen outward and downward around the upper clamp to bring the inner surfaces together and load the free end in the lower clamp vertically. At this time, the leather should be just tight. Use the same mounting method for other specimens. On how to mount the sample, please refer to the figures below.

- Start the machine, Preset flexing times of leather samples. The following is the recommended number of flex cycles:

Dry flex: 500, 1000, 5000, 10000, 20000, 25000, 50000, 100000, 150000, 200000, 250000 cycles

Wet flex: 500, 1000, 5000, 10000, 20000, 25000, 50000 cycles - After completing the number of flexing, stop the machine and remove the specimen, examine it in a good light by naked eyes and magnifier, Report any damage if it occurs and checks the intensity of the cracks if necessary.

The above is the test procedure overview. For detailed explanations, please refer to the required test standard.

FAQs

- Change of shade or greying of the finish film exists, but no further breakage

- Cracking or crazing of the finish

- Loss of adhesion of finish to the leather, color changes

- Loss of adhesion between finish costs, color changes

- Powdering or flaking of the finish costs

- Produces coarse grain lines(also called the pipey grain)

- Loses pattern on the grain

- Cracks on the grain layer

- The fibre turns into powdered scrap

- The fibres continue to be destroyed, and finally, the leather is completely broken

The accessories are divided into standard accessories and optional accessories.

Standard accessories are included with the instrument and are free of charge. The names are as follows:

Press knife(70×45mm) 1 set

Special spanner 1 set

Operation manual 1 set

Optional accessories are the excess accessories chosen by you according to your test needs, and they need to be purchased at an additional cost. Please tell us the names of the specific accessory you need if necessary, and we will list them on the quotation. The options are as follows:

Magnifier

Desiccator

Vacuum pump

Distilled or deionized water

Glass dish

Mandrel

Metal clip

Stereomicroscope

For more details on the bally flexing tester, feel free to contact us.

Leather fatigue refers to the phenomenon that the leather and its coating undergo periodic deformation, which causes its physical and mechanical properties to decrease. This kind of repeated physical damage is lower than the damage strength of the leather.

When the leather is subjected to periodic stress or strain, the surface or the inside of the material produces slight damage. It then gradually develops into a macro crack until it breaks and finally makes the product lose its use function. The flexometer tester is intended to determine the flex resistance of leather.

Performing the bally flex test has great significance for the leather industry.

Guide Producers to Choose Suitable Materials

Testing the resistance of leather materials to flexing is the basic and essential step for manufacturers to commence new product research and development. It can help people in mastering the properties of materials to make the right decision on choosing appropriate raw materials.

Variously candidate materials are tested one by one in the laboratory. According to the data and results of the flexing test of different leather materials, the manufacturer can choose the proper materials. It can meet the quality requirements of the finished product without causing excessive performance.

Evaluate the Product Quality

Bally flex test allows you to understand and grasp the performance and quality of leather or leather products in a very short time. When a bunch of produced leather products are placed in front of you if you are asked to evaluate their quality, how would you judge?

It is a troublesome problem because we cannot directly obtain reliable assessment results simply by observing with eyes and touching with hands. The only way is to use an instrument similar to the Bally flexometer to take samples on-site for fatigue testing. With the support of test results of randomly selected samples, you can estimate whether the same batch of products meets the requirements. The flexing test is an extensively used method to judge the quality level of finished products like leather bags, leather shoes, leather suitcases etc.

Promote the Brand Image

Imagine that you are a leather clothing brand or manufacturer. If you indicate in your adverting that the leather raw materials you use have passed the Bally flex test. You can even put the testing pictures or videos in your ad copy. When these advertisements are launched, the audience will trust you more and have more confidence in your products than bragging about the quality simply? They will think that you are a brand with strict requirements on the quality of your products and a brand responsible to every customer. In this way, your brand image will get people’s positive affirmation virtually.

AMADE TECH is a professional supplier of various leather testing machines. Bally Leather Flexing Tester is one of our hot-selling instruments. Machines with 6 workstations, 12 workstations and 24 workstations are available to suit your different testing requirements.

Welcome to contact us via email: [email protected] or by other channels if you are sourcing the leather flex tester.

This Bally bending fatigue testing machine can be used in many different industries, including leather, clothing, shoes, furniture, luggage, decoration, automobiles and other industries.

Yes, the machine will stop automatically once the preset number of cycles is reached. During the test, you don’t have to stay next to the machine all the time and stop the test manually. As long as the parameters are set, you can do your own thing freely. You can do the result evaluation directly after the bending of the sample is finished. This machine facilitates the work of testers and saves their time.

There are two counting modes for counting the flex cycles: One is the cumulative counting mode: counting from 1 to the preset number of cycles. The other is the countdown: counting from the preset number of cycles to 1. You can choose any method freely.

Yes, the flexing speed and angle are adjustable based on your testing requirements. The stated speed and angle in standards are (100 ± 5) CPM and 22.5° ± 0.5° respectively.

The Tester will be packed by a export wooden case. It can better protect the machine from being damaged during the transportation.

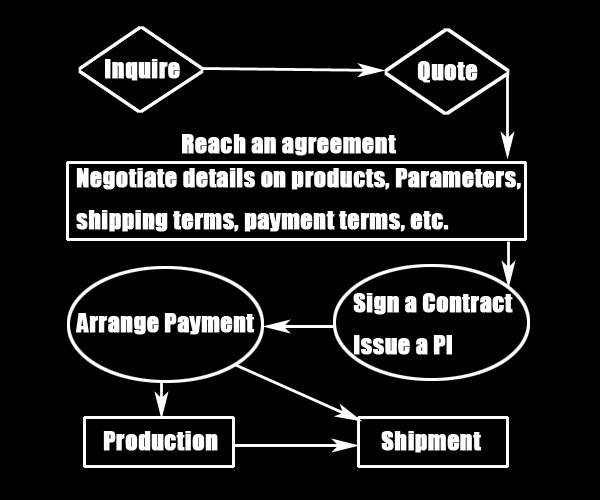

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.