In order to understand the importance of the Cobb test for packaging, we must first know what the Cobb test is.

The Cobb Test is a test that measures the weight of water absorbed by the surface of paper, paperboard or corrugated fiberboard over a specified period of time. Its purpose is to test the water absorption performance of the sample. The increase in mass is called Cobb value, which is expressed in grams per square meter (g/m2).

The larger the Cobb value, the test material has strong water absorption and moisture retention properties, and the smaller the Cobb value is, the test material has the property of resisting water penetration and moisture is not easy to stay. These properties are closely related to the application of materials.

In a broad sense, most of the time when we talk about packaging materials, we refer to paper cartons or corrugated cardboard boxes. Especially corrugated boxes, which play an indispensable role in modern logistics and warehousing. They have important responsibilities for loading, protection and aesthetics. Because of its accessibility, light weight, relatively good structural strength, low cost, and recyclability, corrugated boxes are widely loved and widely used around the world.

However, everything has two sides, and there must be advantages and disadvantages. We know that the material of corrugated cardboard boxes is made of paper. In addition to being unable to resist piercing by sharp tools, there is another disadvantage that it has poor moisture resistance, that is, it has a tendency to absorb water. In the wet and rainy season, if you put an ordinary untreated corrugated carton in a damp basement, after a few days you will find that the whole carton will become soft and deformed so that it loses its loading capacity.

As a carton manufacturer, if your products are used in an environment with high relative air humidity, you need to use materials with poor water absorption ensuring that packaging can resist the possible humid environment during storage or transportation. Otherwise, your products will not be able to complete the functions of loading and storing goods normally, which may cause economic losses to the users.

Furthermore, the water absorption of fiberboard has a great influence on the printing adaptability of water-based adhesives, which will affect the process flow and product quality.

In order to ensure that the selected materials are fully compatible with the use and production process of the corrugated boxes, we urgently need a test to grasp the water absorption of the material in advance during the research and development stage or before formal mass production. So the Cobb test came into being.

The Cobb test result is relatively accurate, and the operation is very simple. The operator only needs to weigh the sample before the test. When one side of the sample is in contact with water for a specified time, then blot the excess water on the sample and weigh it again immediately. The result is expressed by the increased mass of the sample per unit area. The lower the Cobb value the lower water absorption is, the carton can remain more hard and stable under high humidity.

As a packaging user, you can also conduct the Cobb test to check whether the carton you use is up to standard.

In a word, the implementation of the Cobb test has great positive significance on the selection of packaging materials and checking whether the finished cartons meet the moisture-proof requirements.

What Instruments Are Needed for the Cobb Test and Where to Get Them?

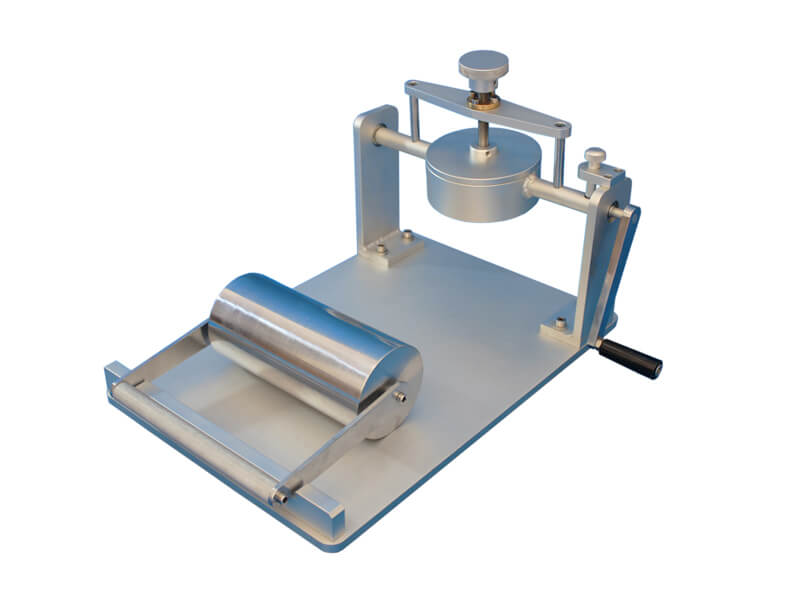

There are 3 types of instruments used for the Cobb test: a Cobb sample cutter, a Cobb testing device, and a digital balance with an accuracy of 0.001g.

You can get them from AMADETECH. As a professional instrument supplier in China, AMADETECH is able to supply various paper and board testing devices and other types of testing machines at competitive prices. All devices are consistent with specifications required by various international standards. If you have any questions, please feel free to get in touch with us.