As we all know, water ingress protection (IP) testing is also called waterproof testing, which contains a series of test approaches to determine how well a device can withstand water exposure. In the IP coding system, The characteristic numerical indicating the waterproofing grade is in the second digit.

It contains ten numbers from 0 to 9 representing different waterproof levels, including protection against water drops, spraying water, splashing water, water jets, water immersion, and powerful high-temperature water jets. 0 is the lowest level of non-protection, and 9 is the highest level of protection.

Of course, test items in different standards are slightly different. For example, ISO 20653 and DIN 40050-9 have more IPX4K and IPX6K than IEC 60529, and use IPX9K instead of IPX9 to indicate high temperature and high-pressure water jetting test.

Waterproof cellphone

Waterproof lamp

Waterproof camera

Waterproof watch

Waterproof testing is a routine experiment that some outdoor and electronic products must do in the research and development stage or before leaving the factory to meet specific application scenarios. Water ingress protection testing involves exposing the device to different water pressure levels, flow rates, and duration depending on the test rating.

This article describes and presents the details of water ingress protection tests from IPX1 to IPX9K from the perspectives of definitions, testing conditions, testing equipment, testing procedures, and assessment criteria. Reading this guide will help you understand and learn about IPX waterproof testing and how to choose suitable equipment.

IPX1 / IPX2 Water Ingress Protection Testing – Vertical Dripping

IPX1/2 Definition

IPX1 is a water ingress protection test that measures how well a device is protected against vertically falling water drops. The device is required to be exposed to water drops equivalent to 1 mm of rainfall per minute for 10 minutes. If the IPX1 test passes, it means that the device enclosure has the ability to protect the equipment inside the enclosure against harmful effects due to vertically falling water drops.

IPX1 drip testing

IPX2 is a water ingress protection test that measures how well a device is protected against dripping water at an angle of 15 degrees. The device is required to be exposed to water droplets equivalent to 3 mm rainfall per minute for 10 minutes in four different positions of tilt. If the IPX2 test passes, it indicates that the device enclosure inclined by up to 15° can protect the equipment inside the enclosure against harmful effects due to vertical drips.

IPX1/2 Testing Conditions

IP Code | Water flow rate | Water pressure | Water temperature | Exposure time | Dripping distance |

IPX1 | 1±0.5 mm/min | - | Should not differ by more than 5°C from the DUT temperature. If the water temperature is more than 5°C below the temperature of the DUT, A pressure balance should be provided for the enclosure (IEC 60529), or measures should be agreed upon between the users of the standard (ISO 20653 & DIN 40050-9) | 10 min | The vertical distance from the water outlet to the top of the DUT: 200 mm |

IPX2 | 3±0.5 mm/min | - | 2.5 min for each position of tilt |

IPX1/2 Water Dripping Testing Equipment

Equipment | Figures | Core Features | Key Parameters |

Box-type IPX1/2 dripping test equipment |  |

|

|

Open-type IPX1/2 dripping test equipment |  |

|

IPX1/2 Waterproof Testing Procedure

Testing Procedure for IPX1:

- Place the device under test (DUT) in its normal operating position on the turntable, ensuring the distance between the turntable axis and the DUT axis is approximately 100 mm, and the water outlet is 200 mm above the top of the DUT. If necessary, we suggest a means similar to binding to fix the DUT to the turntable to prevent falling during testing.

- Preset the water flow rate and test duration through the touch screen, then actuate the machine to allow the turntable to rotate by 1 r/min and simultaneously permit the vertical drips to fall onto the DUT at a rate of 1 mm/min for 10 minutes.

- After the test time is complete, check the DUT for any harmful effects.

Testing Procedure for IPX2:

- Place the DUT in its normal operating position on the turntable and ensure the turntable and DUT axes are on the same line. One more step is to incline the turntable by 15 degrees manually (Ensure the vertical distance between the topmost point of the DUT and the water outlet is 200 mm).

- Preset the required parameters and then start the machine to allow the vertical drips to fall onto the DUT at a rate of 3 mm/min for 2.5 minutes, then repeat this step for the rest 3 directions so that each of the four fixed positions of tilt is tested for 2.5 min.

- Inspect the DUT for any harmful effects when the test is complete.

IPX1/2 Assessment Criteria

- IPX1: The device is qualified if it doesn’t suffer any harmful effects or has no compromise on performance due to vertical water drops.

- IPX2: The device is qualified if it doesn’t suffer any harmful effects or has no compromise on performance due to vertically falling water drops when the device enclosure is tilted at any angle up to 15°.

IPX3 / IPX4 / IPX4K Water Ingress Protection Testing – Spraying & Splashing

IPX3/4/4K Definition

IPX3 is a water ingress protection test that measures the protection of a device against spraying water at any angle up to 60° from the vertical. If the IPX3 test passes, it means that the device enclosure has the ability to protect the equipment inside the enclosure against harmful effects resulting from spraying water.

IPX4 is a water ingress protection test that assesses the protection of a device against splashing water from any direction. If the IPX4 test passes, it indicates that the device enclosure is able to protect the equipment inside the enclosure against harmful effects resulting from splashing water.

IPX4K is a supercharged waterproof test on the basis of IPX4.

IPX4 oscillating-style spray testing

IPX4 hand-held spray testing

IPX3/4/4K Testing Conditions

IP Code | Water flow rate | Water pressure | Water temperature | Exposure time | Spraying distance |

IPX3 | By oscillating tube: (0.07±5%) L/min per holel (IEC 60529) (0.1±5%) L/min per hole (ISO 20653 & DIN 40050-9) | Approx. 80 kPa (ISO 20653 & DIN 40050-9) | Same as IPX1/2 above | 10 min (5 min in one position, 5 min in a position turned by 90° along the horizontal line) | 200 mm |

By hand-hold spray nozzle (10±5%) L/min | 50 ~ 150 kPa | 1 min/m2 At least 5 min | 300~500 mm | ||

IPX4 | Same as IPX3 | Same as IPX3 | Same as IPX3 | Same as IPX3 | |

IPX4K | (0.6±5%) L/min per hole | Approx. 400 kPa | 10 min (5 min in one position, 5 min in a position turned from this position by 90°) | 200 mm |

IPX3/4/4K Water Spraying/Splashing Testing Equipment

Equipment | Figures | Core Features | Key Parameters |

Box-type IPX3/4/4K water spray/splashing test equipment |  |

|

|

Open-type IPX3/4/4K water spray/splashing test equipment |  |

| |

IPX3/4 hand-hold spray nozzle (shower tube) |  |

|

|

IPX3/4/4K Waterproof Testing Procedure

Testing Procedure for IPX3 with An Oscillating Tube:

- Place the sample on the turntable, and use a means to fix it in case of falling during the test if necessary.

- Input the prescribed parameters into the controller, and start the test to allow the spraying water from the holes of the oscillating tube swiveling by ±60° with reference to the vertical plane at a rate of approx. 1s/60° to act on the sample enclosure from a distance of no more than 200 mm, lasting for 5 minutes.

- Turn the sample through a horizontal angle of 90° and continue the test for another five minutes.

- After the spray time, examine the sample for any harmful effects.

Testing Procedure for IPX4/4K with An Oscillating Tube:

The test method of IPX4/4K is the same as that of IPX3 above. A difference is that you need to set the swiveling angle of the tube to 180° (it may not reach 180° in the actual test due to the existence of a sample support rod).

Testing Steps for IPX3/4 with a hand-held spray nozzle (shower tube):

- Place the sample on a flat platform.

- Loosen the adjustment screws on both sides of the shower apparatus, and move the movable shield forward 30 degrees so that 30° of the curved surface is blocked to meet the relevant test requirements of IPX3 (if the movable shield is not moved, the curved surface of the entire shower head will be exposed, and to spray water over the sample enclosure, which meets the relevant test requirements of IPX4,) and then tighten the screws.

- Open the apparatus valve to start spraying water, and adjust the water pressure to 50 ~ 150 kPa or water flow rate to (10 L ± 5%) / min.

- For IPX3, Position the spay nozzle to allow it to spray water through an angle of 120°, 60° on either side of the vertical from a distance no more than 500 mm for a total of at least 5 min (1 min/m2). For IPX4, spray the sample from all practicable directions(Based on IEC 60529)

- Inspect the DUT for any harmful effects.

IPX3/4/4K Assessment Criteria

The device is qualified if it doesn’t suffer any harmful effects or has no compromise on performance due to spraying water(IPX3) or splashing water(IPX4/4K).

IPX5 / IPX6 / IPX6K Water Ingress Protection Testing – Jetting

IPX5/6/6K Definition

IPX5 / IPX6 is a water ingress testing that measures how well a product can resist water damage from low-pressure water jets (IPX5) or powerful water jets (IPX6). This test is conducted by jetting water on the sample from all angles for a certain period of time.

IPX6K requires the DUT to be exposed to strong high-velocity water with increased pressure.

IPX6K jetting testing

IPX5 hand-held jetting testing

IPX5/6/6K Testing Conditions

IP Code | Water flow rate | Water pressure | Water temperature | Exposure time | Jetting distance |

IPX5 | (12.5±5%) L/min | Approx. 30 kPa | Same as IPX1/2 above | 1 min/m2 At least 3 min | 2.5 ~ 3 m |

IPX6 | (100.0±5%) L/min | Approx. 100 kPa | 1 min/m2 At least 3 min | ||

IPX6K | (75.0±5%) L/min | Approx. 1000 kPa | At least 3 min |

IPX5/6/6K Water Jetting Testing Equipment

Equipment | Figures | Core Features | Key Parameters |

Box-type IPX5/6 /6K water jetting test equipment |  |

|

|

Open-type IPX5/6 /6K water jetting test equipment |  |

|

IPX5/6/6K Waterproof Testing Procedure

- Secure the sample on the turntable with a means like binding to prevent falling during testing.

- Select a corresponding nozzle and adjust the water flow to 12.5L/min (IPX5), 100L//min (IPX6), or 75L/min (IPX6K).

- Start the machine to jet water for 1 minute per square meter of the sample in revolution, with a minimum of 3 minutes. (when the open-type test equipment is used, Keep the distance between the nozzle and the sample between 2.5 meters and 3 meters and constantly adjust the nozzle angle to ensure that water wets every part of the sample. )

- Check if the sample remains undamaged and functioning properly after the test.

IPX5/6/6K Assessment Criteria

The device is qualified if it doesn’t suffer any harmful effects or has no compromise on performance due to water jets (IPX5) and powerful water jets (IPX6/6K).

IPX7 Water Ingress Protection Testing – Temporary Water Immersion

IPX7 Definition

IPX7 waterproof testing is used to determine whether the device under test can resist temporary immersion in water. The sample is required to be soaked in the water at a depth ensuring the highest point of the DUT is at least 150 mm but less than 1000 mm away from the water surface for 30 min.

IPX7 water immersion testing

IPX7 Testing Conditions

IP Code | Water flow rate | Water pressure | Water temperature | Exposure time | Immersion depth |

IPX7 | - | - | Should not differ by more than 5°C from the DUT temperature, except that the DUT is energized and/or its parts are in motion (IEC 60529). | 30 min | The vertical distance between the water surface and the highest point of the DUT is equal to or more than 150 mm but less than 1000 mm |

IPX7 Water Immersion Testing Equipment

Equipment | Figures | Core Features | Key Parameters |

Plain immersion tank |  |

|

|

Immersion tank with an electric hoist |  |

|

IPX7 Waterproof Testing Procedure

- Place the DUT in the water tank.

- Fill the water tank with fresh water up to the required depth with the help of the ruler, ensuring that the lowest point of the DUT with a height less than 850 mm is 1000 mm below the water surface or the highest point of the DUT with a height equal or greater than 850 mm is 150 mm below the water surface.

- Continue the test for 30 minutes (Visually observe whether there is water leakage during the immersion), then remove the DUT from the tank and examine it for any harmful effects.

IPX7 Assessment Criteria

The device passes the test if it doesn’t suffer any harmful effects or has no compromise on performance due to temporary immersion in water.

IPX8 Water Ingress Protection Testing – Pressurized Water Immersion

IPX8 Definition

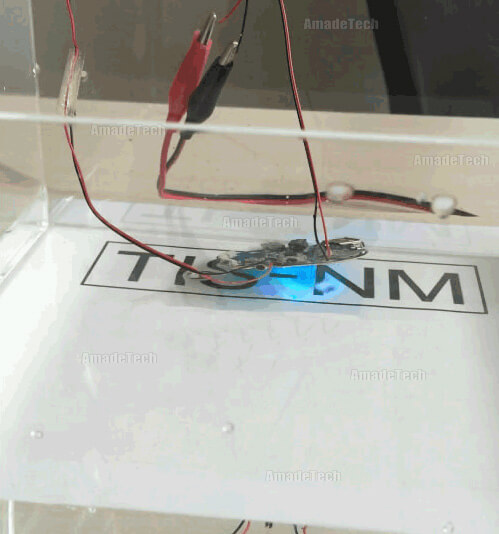

IPX8 is intended to assess whether or not a device is suitable for continuous immersion in water under specific conditions agreed upon by interested parties. These conditions have to be more severe than that of IPX7. This testing is suitable for underwater connectors, diving goggles, swimming pool lights, underwater cameras, watches, water meters, underwater sensors, and more.

IPX8 Pressurized Immersion Testing

IPX8 Testing Conditions

IP Code | Water flow rate | Water pressure | Water temperature | Exposure time | Immersion depth |

IPX8 | - | - | - | By agreement | By agreement |

IPX8 Pressurized Water Immersion Testing Equipment

Equipment | Figures | Core Features | Key Parameters |

IPX8 pressurized water Immersion tank |  |

|

|

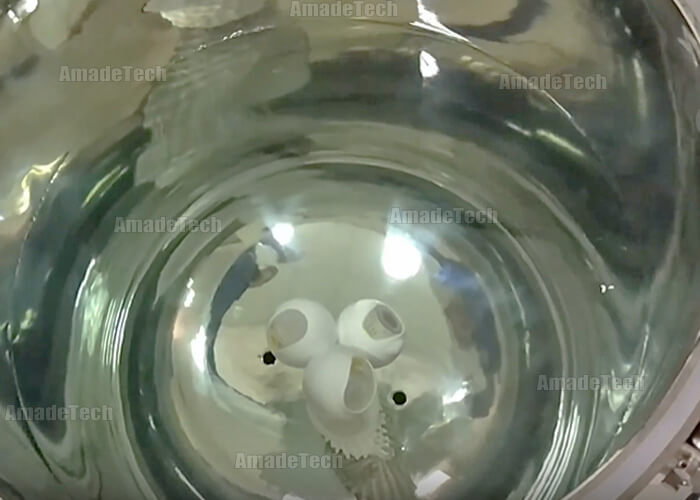

IPX8 Waterproof Testing Procedure

- Place the sample in the water tank and fix it to the bottom.

- Add water into the tank until the required depth is achieved, ensuring the sample is completely submerged.

- Close the tank lid and fasten it with a corresponding locking device in case of air leakage.

- Input the corresponding pressure equivalent to the required depth of water and duration into the control system.

- Start the machine to pressurize the tank until the preset value is achieved, then the device starts timing automatically.

- After the test time, relieve pressure in the tank, and then take the sample out to examine for any harmful effects.

IPX8 Assessment Criteria

The device is qualified if it doesn’t suffer harmful effects due to the ingress of water in quantities.

IPX9 / IPX9K Water Ingress Protection Testing – High Pressure and Temperature Water Jetting

IPX9/9K Definition

IPX9/9K waterproof testing is used to measure whether or not a device can resist high-temperature and high-pressure water jets. It is the highest level among the IPX waterproof test items, and the test requirements are also quite high.

The IPX9/9K testing is performed by allowing strong water jets with high temperatures to spray onto the rotating sample enclosure from different directions.

IPX9 water spray testing

IPX9/9K Testing Conditions

IP Code | Water flow rate | Water pressure | Water temperature | Exposure time | Jetting distance |

IPX9 | (14~16) L/min | Approx. 8000~10000 kPa | (80±5)°C | 30 s per position 1 min/m2 At least 3 min | (175±25) mm (IEC 60529) (100~200) mm (ISO 20653/DIN 40050-9) |

IPX9/9K High Pressure and Temperature Water Jetting Testing Equipment

Equipment | Figures | Core Features | Key Parameters |

IPX9/9K high pressure and temperature water spray test chamber |  |

|

|

IPX9/9K Waterproof Testing Procedure

- Place the sample on the turntable and regulate corresponding nozzles to achieve the required spray distance, then fasten the sample with a string to prevent falling during testing.

- Preset the test conditions on the touch screen and leave a period of time to get the water heated.

- Start the test after the required water temperature is achieved, allowing water from 4 nozzles to spray onto the rotating sample in turn. Each nozzle works for 30 s, lasting at least 3 min in total.

- When the spraying is complete, Remove the product from the chamber and inspect it for any harmful effects.

IPX9/9K Assessment Criteria

The device is qualified if it doesn’t suffer any harmful effects or has no compromise on performance due to high temperature and pressure water jetting from any direction.

Final Thoughts

Water Inpress Protection testing takes up most of the test content of the entire IP test, and it plays an indispensable role in the development and production of outdoor products. As mentioned above, different products require different levels of waterproof testing. Only when you have an in-depth understanding of them can you match the most suitable waterproof test for your products.

If you have more questions about IP waterproof testing, please directly contact AmadeTech. AmadeTech is a manufacturer and supplier of waterproof testing equipment solutions and equipment. We can provide a full set of IP Testing Euipment in traditional styles and customized styles. In many cases, due to the distinctive size, shape, and other special requirements of the product to be tested, conventional equipment models may not be able to meet your testing needs. AmadeTech can make personalized solutions according to your requirements to fit your testing samples. And we can integrate IPX1 to IPX6 test functions into one waterproof test chamber.

AmadeTech always welcomes your inquiries.