Crimp Pull Tester China Manufacturer and Supplier

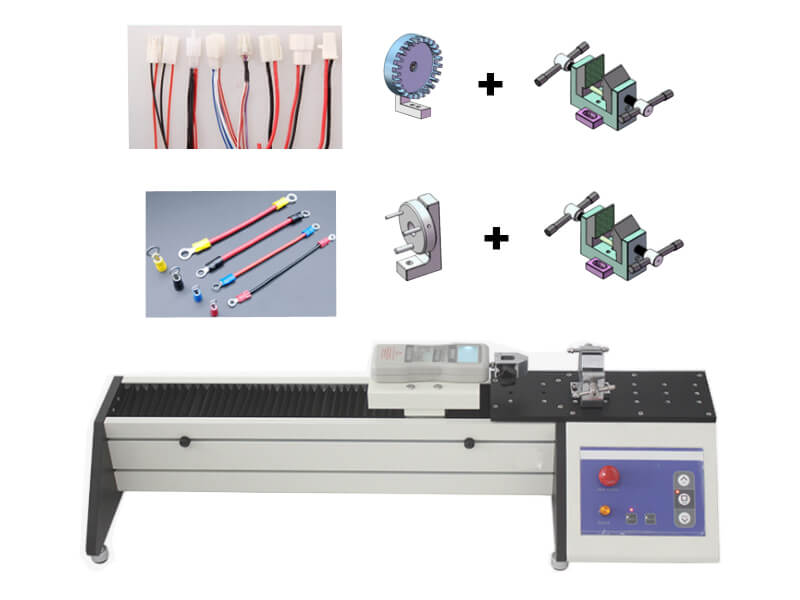

Wire Crimp Pull Tester is specially used to determine the pull-off force of various crimped wire terminals, crimped connectors, or wire harness terminals when separated from the wires or cables. It is usually also called the wire terminal pull tester or cable pull tester.

Wire harnesses are widely used in home appliances, automobiles, medical equipment, and other fields. Strictly speaking, any wire terminals or wire harnesses need to be performed the pull test to ensure the product’s reliability. The pull test is a widespread method to determine the quality of wire terminal crimping. Since the pull-off strength of the terminal crimping is affected by the suddenly applied force and the pulling rate, it is usually required to use a constant-rate motorized pull tester to ensure the repeatability of each test result.

There are several different crimp pull test equipment for performing the wire terminal pull test. AMADE develops and produces vertical and horizontal wire terminal pull testers by manual operation and motorized and intelligent wire pull testers in a horizontal structure. The following are the specifications of these wire crimp pull testers.

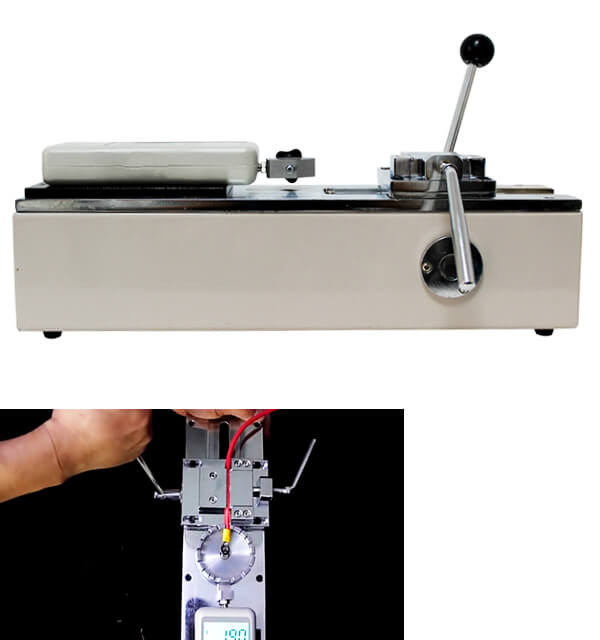

Manual Crimp Wire Pull Tester

- Model: AT-U2-51A

- Type: Horizontal

- Driving method: By quick-action Hand Lever

- Digital push pull gauge: Up to capacity of 500 N

- Overall dimension: 450 x 100 x 130 mm

- Weight: appr. 11 kg

- Data output: RS 232 or USB

- Test type: Destructive test

- Gripping fixtures:

H39 Wire terminal pull grip (Rotating disk with slot)

H39A Ring terminal fixture

H35 & H36 Universal wire terminal grips

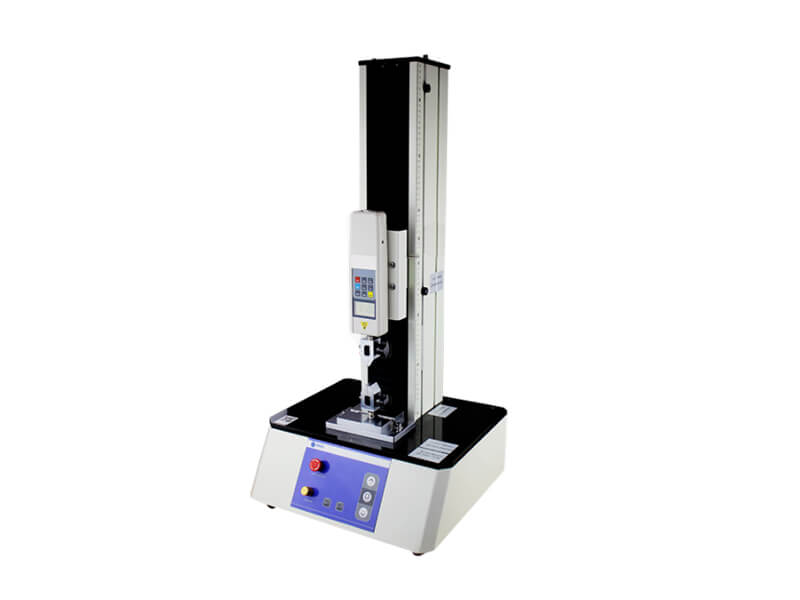

Manual Wire Crimp Pull Tester

- Model: AT-U2-70-9

- Type: Vertical

- Driving Method: By handwheel

- Digital push pull gauge: Up to capacity of 500 N

- Overall dimension: 250 x 350 x 510 mm

- Weight: appr. 15kg

- Data output: RS 232 or USB

- Test type: Destructive test

- Gripping fixtures:

H34 Adjustable dual roller grip (Fast lock and loosen the sample)

H39 Wire terminal pull grip (Rotating disk with slot)

H39A Ring terminal fixture

H35, H36 Universal wire terminal grips

Motorized Crimp Pull Tester

- Model: AT-U2-780

- Type: Horizontal

- Driving mode: By Frequency converter motor

- Digital push pull gauge: Capacity 500 N or 1000 N optional

- Overall dimension: 930 x 260 x 230 mm

- Weight: appr. 28 kg

- Speed control: Fixed speed of movement (10 ~ 350 mm / min settable)

- Data output: RS 232 or USB

- Test type: Destructive test

- Gripping fixtures:

H39 Wire terminal pull grip (Rotating disk with slot)

H39A Ring terminal fixture

H35, H36 Universal wire terminal grips

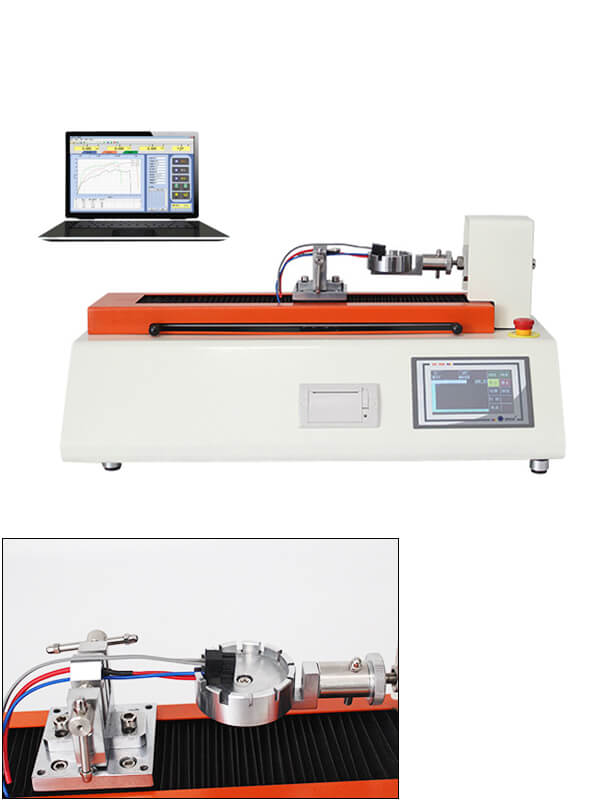

Computerized Crimp Wire Pull Tester

- Model: AT-U2-980-2 / 980A-2

- Type: Horizontal

- Driving mode: Stepping motor

- Force sensor: Capacity 1000N (High precision)

- Overall dimension: 300 x 420 x 650 mm

- Weight: Appr. 28 kg

- Speed control: Fixed speed of movement (1 ~ 500 mm / min settable)

- Data output: LCD touch screen / Computer output, thermal printer

- Test type: Destructive test & non-destructive test

- Test Function:

Measure Breaking force of the wire terminal

The hold time of the terminal’s fixed force

Curve graphs of the force / displacement / time changing - Gripping fixtures:

H39 Wire terminal pull grip (Rotating disk with slot)

H39A Ring terminal fixture

H35, H36 Universal wire terminal grips - The Professional test software is also available

Summary of Crimp Wire Pull Testers

Although the manual wire crimp pull tester is cheap and simple to configure, the test speed is not controllable due to users’ manual operation on the wheel or lever. The force applied is easy to be changed between different tests and operators, so the results of the manual pull tester measuring the pull-out force of the wire terminal are usually not comparable.

Some wire pull test standards require using a constant-rate cable pull tester to test the pull-off force of crimped wires to ensure the repeatability and reliability of each test result. The only way to achieve the consistency of the wire terminal pull test results is to use the electric/motorized wire pull tester.

Wire Crimp Pull Test Standards for Reference

- UL486A/B

- JIS C2805

- DIN46249

- ASTM B913

- SAE AS39029/AS7928

- IEC60352-2

- BS 5G 178

- ISO 1966

- DEF STAN 59-71

Application Objects of Wire Crimp Pull Testers

- Ring terminals

- Spades & forks terminals

- Pin terminals

- C45 terminals

- Blade terminals

- Hook terminals

- Quick-disconnect terminals

- Bullet terminals

- Butt terminals

- Flagged terminals

- Open barrel terminals

Digital Push Pull Gauge

Grips of the Wires Terminal Pull Tester

Wire Crimp Pull Grip

Ring terminal pull test fixture

Universal wire terminal pull test grips

Dual roller grip for wires

Wire Crimp Pull Grip

- Model: H39

- Specifications: Multiple slot widths, up to 6.4 mm

- The dimensions are 2.0 mm, 2.4 mm, 2.8 mm, 3.2 mm, 3.6 mm, 4.0 mm, 4.4 mm, 4.8 mm, 5.2 mm, 5.6 mm, 6.0 mm, 6.4 mm

- Capacity: 1000 N

- Application: Rotate the wheel to the desired size of the slot. It is used for wire crimp pull test

Ring Terminal Pull Test Fixture

- Model: H39A

- Specifications: the sizes of three pins:

① Dia.: 0.5 mm, Height: 15 mm

② Dia.: 0.4 mm, Height: 15 mm

③ Dia.: 0.2 mm, Height: 15 mm - Capacity: 1000 N

- Application: Used for the ring terminal pull tests

Adjustable Dual Roller Grip

- Model: H34

- Specifications:

- The thickness of sample that can be clamped: 0 ~ 20 mm

- Width of the sample that can be clamped: 0 ~ 15 mm

- Height of fixture: 60 mm

- Capacity: 500 N

- Application: Quick clamping of wires/cables, adjustable clamping spacing

Universal Wire Clamping Fixture

- This fixture is a standard configuration of the model AT-U2-51-A wire pull tester

Other Wire Terminal Pull Test Grips

- H35 Universal wire pull test grips

- H36 Universal wire crimp pull test grips

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE sales specialists will respond within one working day.