Vacuum Drying Chamber China Manufacturer & Supplier

Vacuum Drying Oven is a frequently used drying instrument in the laboratory, featuring an artificial vacuum environment to especially dry heat-sensitive, easily decomposed, and easily oxidized materials.

The interior of the chamber is vacuumed by a vacuum pump prior to drying. It is allowed to be filled with inert gas if necessary.

A vacuum pump paired with the drying oven can be provided if requested.

The vacuum drying chamber can minimize the damage and change for the specimens to the utmost extent during the drying at high temperatures. Reducing the possibilities of desquamation and oxidation reaction in the drying process is also the shining point of this vacuum drying oven, which is the reason why it is well applicable to test pieces with active chemical properties. Such as flammable solvents evaporation, although it is with a high risk of explosion if operated in an ordinary drying oven, danger can be avoided once putting the solvents into a vacuum drying cabinet with a low pressure to evaporate.

Both benchtop and vertical vacuum drying ovens are available from Amadetech. In order to meet various needs of dimensions and applications, our vacuum drying oven’s capacities cover from 10 liters to 913 liters.

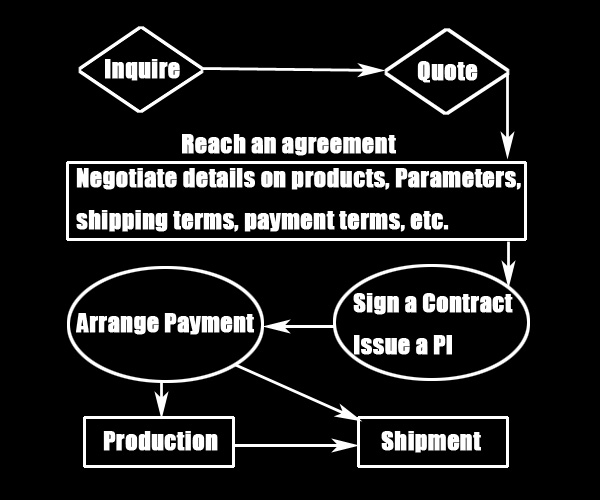

INQUIRE

Different Configurations

- Sorted by working cabinets: single cabinet, 2 cabinets, 3 cabinets.

- Sorted by input powers: 300W, 400W, 550W, 650W, 700W, 850W, 870W, 1450W, 1500W, 1550W, 1800W, 2100W, 3800W, 5600W etc.

- Sorted by shelves’ quantity: 1 / 2 / 3 / 4 / 5 / 6 pcs.

- Sorted by temperature control ranges: RT 10 ~ 65℃, RT 10 ~ 100℃, RT 10 ~ 200℃, RT 10 ~ 250℃.

- Sorted by special Application fields: Special for chemical use, Special for biology use, special for electronics, batteries, semiconductor components, etc.

- Welcome to contact Amade for more product details to meet your requirements.

Vacuum Drying Oven Features

- Housing is made of cold-rolled steel sheets through precision welding and coated with quality baking varnish to ensure smoothness and fastness.

- The cuboid chamber is equipped with multideck racks to maximize the working capacity.

- The tempered glass with two layers on the door offers a clear view for inspection.

- The degree of tightness of the door when closed is adjustable.

- A door gasket fabricated from integrally molded silicone rubber ensures a high vacuum of the drying chamber during use.

- The interior can be filled with inert gases(optional function).

- There are double digital screens to indicate the set value and real-time parameters simultaneously.

- Microprocessor temperature controller provides accurate and reliable running data to reduce the drying period by 40% compared with the traditional equipment.

- A vacuum environment with low pressure offers high resistance of test pieces to oxidization in the whole process of dry.

- The drying process is programmable(optional function).

- Fitted with over-temperature protection and power-off protection to prevent a hazard to the maximum.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.