UN38.3 Battery Thermal Test Chamber China Manufacturer

Battery Temperature Cycling Test Chamber is also called the thermal test chamber, used to simulate the anticipated exposure to low and high environmental temperature changes that cells, batteries, battery modules, battery packs and systems would likely experience during service life to verify their safety performance under such conditions.

The thermal cycling chamber is one of the commonly used lithium-ion battery safety testing machines. At the same time, this battery thermal test chamber can also be used for rapid temperature variation simulation tests of electronic components, auto parts, home appliance parts and other products.

The inner chamber of the temperature cycling testing equipment is made of 304 stainless steel to ensure corrosion and rust resistance and provides flexible inner dimensions to accommodate your specimens. Thanks to the application of high-performance refrigeration compressors and nickel-chromium alloy electric heating tubes, coupled with mature refrigeration and heating systems, this thermal cycling testing machine can achieve rapid temperature changes up or down within 30 minutes in the range of -40℃ to +85℃ to meet your various temperature needs.

In addition, the machine adopts PLC programmable controller. Before the test, you are required to preset multi-segment operation commands on the LCD touch screen. During runtime, the system will enable segmented control and execute the program step by step according to the set steps to allow the specimens inside the chamber to be subjected to the specified temperature cycles.

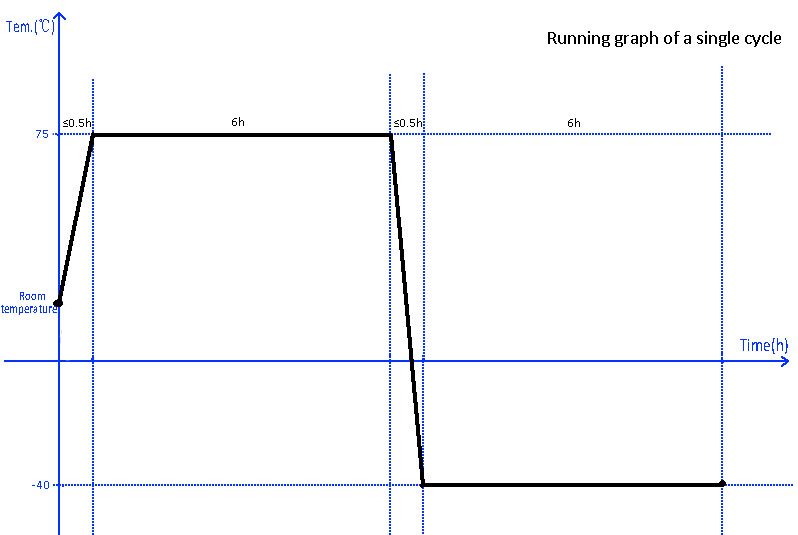

We take the thermal test in UN38.3 as an example. After putting the cell or battery sample into the test chamber, set up the running program and start the test. When the heating system works, the temperature in the chamber will soon climb from room temperature to 75℃ and remain for 6 hours. Then the compressor is actuated automatically to start the cooling, reducing the temperature in the chamber from 75℃ to -40℃ within 30 minutes, and keeping it at that temperature for 6 hours.

The above is a single cycle. The temp. cycle chamber will repeat this single cycle 10 times according to the set program to complete the entire test.

Our temperature cycling test chamber’s maximum allowable temperature range is as low as -70℃ and as high as 150℃. To avoid performance waste and help you save costs, we will recommend you the model of the most suitable test range according to your test requirements or the standards you follow.

If you require to carry out a thermal abuse test on cells or batteries, please click HERE to learn more about our thermal abuse test chamber.

Battery Thermal Cycling Test Standards

- UN38.3

- UL 1642

- UL 2054

- IEC 62660

- EN 50604-1

- ISO 12405-3, etc.

Main Technical Specifications

| Model | AT-L5011 |

| Temperature Range | -70°C ~ +150°C (The specific range will be subject to your test requirements.) |

| Temperature Control Accuracy | ± 0.01 °C |

| Temperature Fluctuation | ≤ ± 0.5°C |

| Temperature Uniformity | ± 2 °C (measured by the national measurement standard nine-point measurement method) |

| Heating Rate | -40°C to +75 °C temperature conversion within 30 minutes (average temperature rise, non-linear no load) |

| Cooling Rate | 75°C to -40°C temperature conversion within 30 minutes (average temperature rise, non-linear no load) |

| Cooling Method | Air cooling |

| Test Chamber Internal Dimensions | 500 (W) x 600 (H) x 500 (D) mm (150L)

80L/225L/408L/800L/1000L also available |

| Main Materials | Internal of chamber: SUS304 stainless steel plates

External of chamber: Cold rolled steel sheet with baking paint treatment |

| Thermal Insulation Material | PU foam |

| Power Supply | 3 Phase 4 wires + reliable grounding wire

AC 380V +/- 10%, 50 Hz,12 kW, 32 A |

| Safety Protections | Overtemperature protector

No fuse protection switch Compressor high and low pressure protection Compressor overload and overheating protection, etc. |

Battery Thermal Test Chamber Features

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.