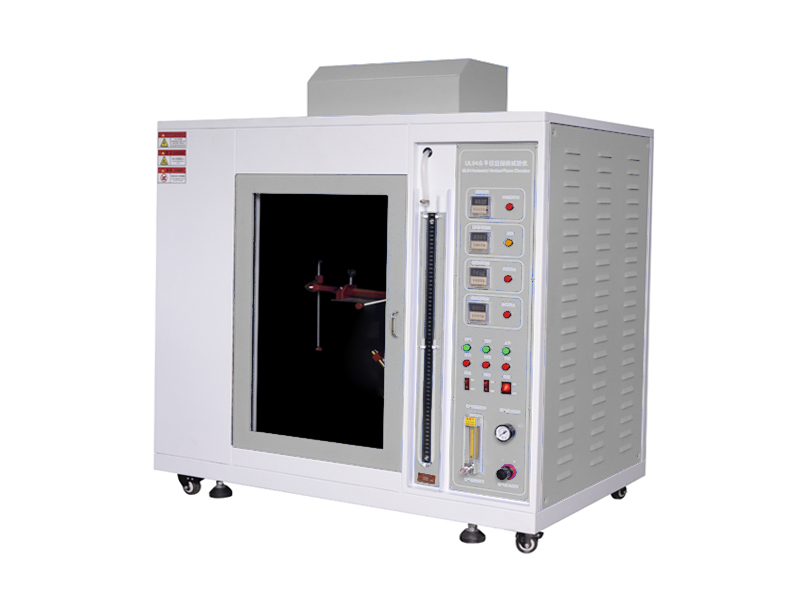

UL94 Horizontal & Vertical Burning Test Equipment China Manufacturer

UL94 Horizontal & Vertical Flame Chamber is an essential flammability test equipment intended to determine the burning rating of plastic materials used for parts in devices and appliances under specified conditions. It can help users grasp the tendency of materials to extinguish or spread after being ignited, and the results can be used as a strong basis for evaluating the flame retardancy of materials.

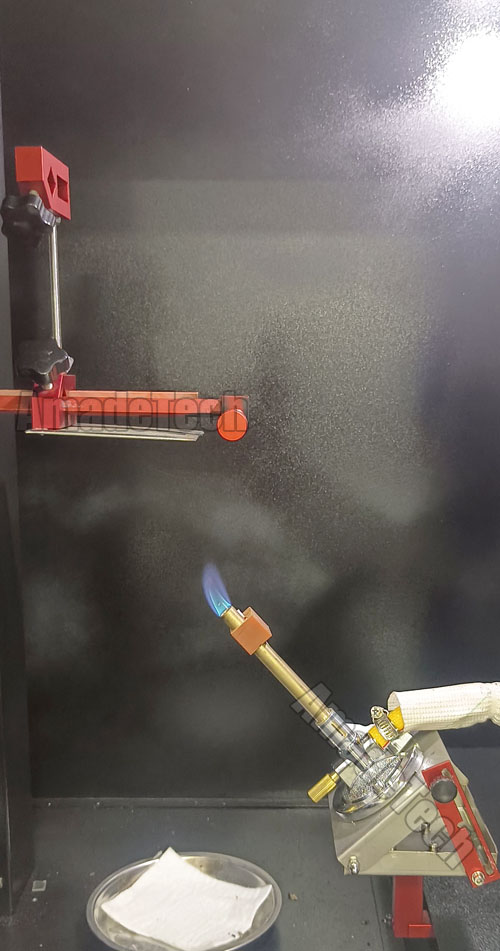

The plastic sample of specified shape and size is clamped and fixed in the fixture matching the test item according to the specified posture and angle. The built-in burner with given power can automatically traverse to the preset flame application position under the sample under control to apply flame to the sample for a specified time. After the applied flame is removed, the burning state of the sample needs to be continuously observed. If the sample continues to burn, the afterflame time, afterglow time, or the time spent on the specified flame combustion stroke can be displayed and recorded for corresponding comparison and subsequent calculations.

Fume Chamber

AmadeTech UL94 Horizontal & Vertical Flame Chamber features an enclosed space of at least 0.5 m3 to provide a test environment that is not disturbed by the wind while the specimen is burning. An exhaust fan is built in the chamber to extract fume or toxic gas after the test. To allow you to observe the combustion situation of the sample conveniently, a heat-resistant glass is equipped in the door. In addition, we have painted the inner wall of the chamber black to facilitate better observation. In order to ensure the safety of the test, we have equipped a gas leakage detection and alarm device in the inner box. Once a leak is detected, the device will sound an audible warning and automatically cut off the gas supply.

Bunsen Burner

The Bunsen burner of UL94 burning tester’s power from AmadeTech is available in 50 W or 500 W to fit different test items. The burner is originally from America and consists of a tube with a length of (100±10) mm and an inside diameter of (9.5±0.3) mm.

When the burner tube is in a vertical state, it can be manually tilted 20° or 45° to the direction of the fixture assembly and locked with the aid of a special limit device. The burner has one-key ignition and an automatic ignition function. According to different test needs, you can adjust the flame state and height by turning the corresponding adjustment devices of the equipment.

When given a forward command, the burner can automatically move horizontally to the ignition position of the sample to apply the flame. When the specified flame application time is reached, the burner will automatically return to the starting position.

Fixture Assemblies

With the help of ingenious design, this flame test chamber is compatible with different fixture types to realize the multi-purpose function of one machine. We can flexibly configure the fixture assembly inside the chamber to perform horizontal or vertical flame tests according to your testing needs. The clamped sample can realize the movement in the up, down, front, back, left, and right directions to meet the diversified needs of sample positioning.

Specifically, the UL94 test items that this machine is compatible with include Horizontal Burning Test: HB, 20 mm Vertical Burning Test: V-0, V-1 or V-2, Thin material vertical burning test: VTM-0, VTM- 1 or VTM-2, and 500 W (125 MM) vertical burning test: 5VA or 5VB (requiring high-power burner and larger chamber).

If you are want to conduct the Radiant Panel Flame Spread Test or Horizontal Burning Foamed Material Test: HBF, HF-1, or HF-2, Please consult us individually for the corresponding equipment, and we will give you a quotation.

Control Panel

The control panel of our conventional UL94 flammability test equipment consists of physical buttons and LED displays. Each key has its specific purpose. You can efficiently operate this device with the text description below the buttons. It should be noted that when doing a horizontal or vertical combustion test, you need to manually press the “Afterflame out” button and “Afterglow out” button at the specified time point to record the corresponding elapsed time, and the corresponding data will be displayed on the displays.

In addition, AmadeTech can also supply UL94 test equipment with a touchscreen controller. It can realize data input and calculation, store multiple sets of historical test data, and also supports on-site printing of test results.

In addition, AmadeTech can also provide more flame retardant testing equipment for plastic materials, such as:

Compliant Test Standards

- UL94 (Horizontal Burning test: HB)

- UL94 (50 W (20 mm) Vertical Burning Test: V-0, V-1 or V-2)

- UL94 [500 W (125 mm) Vertical Burning Test: 5VA or 5VB] (Changing the chamber size and burner required)

- UL94 (Thin Material Vertical Burning Test: VTM-0, VTM-1 or VTM-2)

- ISO 1210, ASTM D 635, D4804, ASTM D 3801, ASTM D 4804, ISO 9773, IEC 707, IEC60695-11-10, etc.

Main Technical Specifications

| Model | AT-P6002 |

| Volume of chamber | More than 0.5 m³, black interior |

| Test flame | 50W or 500W |

| Burner tube | Internal diameter: φ(9.5 +/- 0.3) mm, length: (100+/-10) mm |

| Burning angle | 0°, 20°, 45° adjustable |

| Height of flame | 20 mm ~ 175 mm adjustable |

| Flame application time | 0 ~ 99 m and 99 s settable |

| Afterflame time | 0 ~ 99 m and 99 s settable |

| Afterglow time | 0 ~ 99 m and 99 s settable |

| Timer accuracy | ± 0.1 s |

| Gas source | Methane / LPG / natural gas with purity above 98% (prepared by users) |

| Power supply | 220 V, 50 Hz or 110 V, 60 Hz selectable |

| Dimensions | 1150 mm (L) × 650 mm (D) × 1250 mm (H) |

UL94 Horizontal/Vertical Flame Chamber Features

- Made of rugged steel to ensure structural strength and durability.

- Compact size takes up less space.

- Built-in a lamp inside the chamber to facilitate the specimen mounting.

- Equipped with an exhaust fan to remove the products of combustion.

- Fitted with a door consisting of a piece of transparent glass to guarantee that specimens can be seen throughout the test.

- The burner used is the brand designated by UL, with angle adjustment (0°, 20°, 45°) and a precise gas control system consisting of a gas flowmeter, pressure regulator, and pressure gauge.

- Compatible with different fixture kits to complete different test items in UL94.

- Provided with flame application timer, afterflame timer, afterglow timer, etc., to record the required test parameters.

- Chamber size and configurations are customizable as per requirements.

FAQs

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.