Packaging Transportation Simulation Vibration Tester China Manufacturer

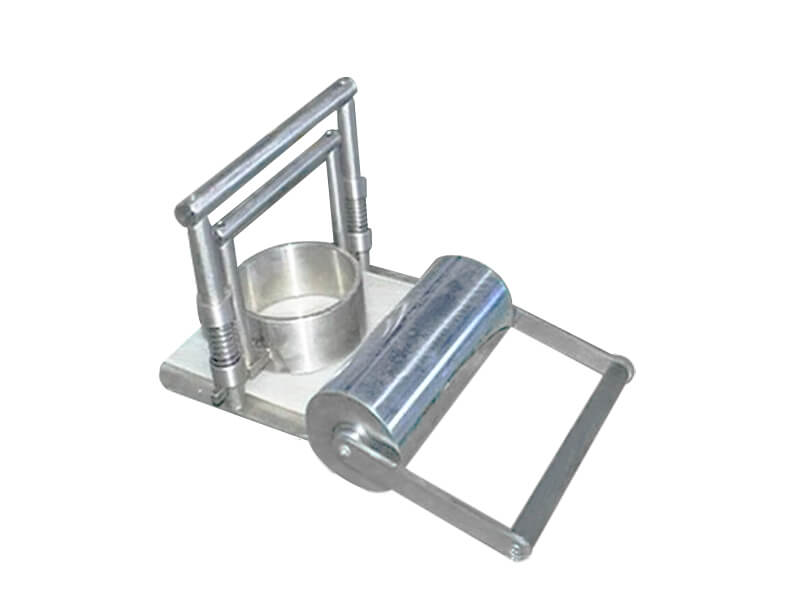

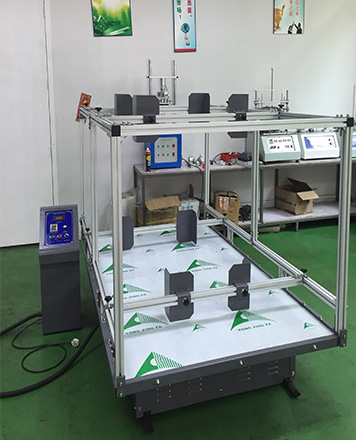

Rotary Type Vibration Test Machine is intended to simulate the vibration during cargo transportation to figure out whether the package and the content inside can resist these conditions.

The eccentric bearing inside the machine is able to produce an elliptical motion track during rotation, generating the fixed displacement at one-inch peak to peak and at a predetermined frequency.

Although It is a non-simulation Integrity performance vibration test, It is widely used to test the strength of the combination of products and the package and the robustness of the package.

It effectively helps people in determining the strength of the interior goods during transportation and the protective ability of the package to the contents when subjected to rotatory vibration at a constant frequency. It can be used as a single test or as part of a series of tests.

Test Principle

A package sample with the same weight as that in practice is placed on the vibrating table and clamped firmly with the guide rails and four edge fixtures to prevent it from moving during the test.

The table shakes the sample at a low-frequency oscillation with a fixed displacement. The temperature and humidity conditions, test duration, vibration frequency, and sample placement state are all predetermined.

If necessary, a specific load can be added to the test sample to simulate the condition that the package is at the bottom of a stack.

The influence of the simulated working conditions obtained in the laboratory on the goods is used as the basis for the evaluation of the product and the packaging.

Test Standards

- ASTM D999 Standard test methods for vibration testing of shipping containers

- ISTA 1A Non-simulation integrity performance test procedure – Rotary vibration test – Fixed displacement

- ISTA 2A Partial simulation performance test procedure – Rotary vibration test – Fixed displacement

- EN-71

Main Technical Parameters

| Model | AT-P8005 |

| Max. Load | 100 kg or specified |

| Work Table Size | 1200 × 1000 mm or specified |

| Frequency Range | 100 ~ 300 rpm |

| Amplitude | 1 inch (25.4 mm) (meets ISTA 1 A / EN71) |

| Mode of Vibration | Rotary type |

| Simulation speed | 25 ~ 40 km / h |

| Speed Accuracy | ≤ ± 3 RPM |

| Motor Power | 1 HP |

| Testing Time Set Range | 0 ~ 999 h 99 m |

| Power Supply | AC 220 V, 50 Hz or Specified |

| Weight | About 150 kg |

Rotary Vibration Test Machine Features

- This machine has reasonable design, compact structure, safe and stable operation.

- Fitted with the synchronously silent belt transmission, with low noise.

- The package sample is clamped at vertical edges by 4 fixtures , with the help of the guide rails.

- Adding one more layer of guardrail with more fixtures to accommodate higher packages is available.

- Controlled by a micro processor, enabling the vibration to stop automatically once the preset parameter is reached.

- The table size, load and the height of the guard rails can be cusomized according to specific requirements.

- The vibration table and the control box are separated from each other to guarantee the safety of the operator during the test.

- The vibration frequency can be presented on an LED with high accuracy.

- The bottom of the machine is made of the heavy-duty channel steel with damping rubber pads, which is easy to install and able to run smoothly without installing anchor screws.

- Equipped with a DC motor for speed regulation, with stable operation and strong load capacity.

- The vibration table moves in a manner of rotary motion to shake the sample.

- It is with a decent price that all clients can afford it.

What’s the Significance of Performing Rotary Vibration Test on the Package Box?

In our daily life, no matter what the product is, it will inevitably suffer vibration during transportation. The difference is just the magnitude of the vibration. The influence arising from it is different according to different products.

For example, the glass and earphones are also transported by a vehicle. Obviously, the glass is more sensitive to vibration than the earphones in the process of shipment and has stricter requirements for the vibration level.

In order to choose a safe and suitable transportation method and eliminate the loss caused by transportation, we must find a device that can conduct packaging vibration testing.

Usually, the packaging vibration testing is carried out using a rotary vibration test machine or random vibration test machine.

Both can reproduce the vibration that may be encountered during the transportation journey, so as to detect whether the package and content will be damaged, and then try to find a reasonable packaging solution.

The benefits of rotary vibration testing:

- Helps analyze the strength of the product packaging, evaluate whether the existing packaging can protect products inside during shipment, so as to find a better packaging solution.

- Able to reduce product damage caused by defective packaging, thus to save unnecessary costs.

- Conducive to satisfying your customers. When your customers receive a good package and products in good condition, they will feel particularly pleased, and give you a good comment.

What’s the Difference Between Rotary Vibration Test Machine and Random Vibration Test Machine?

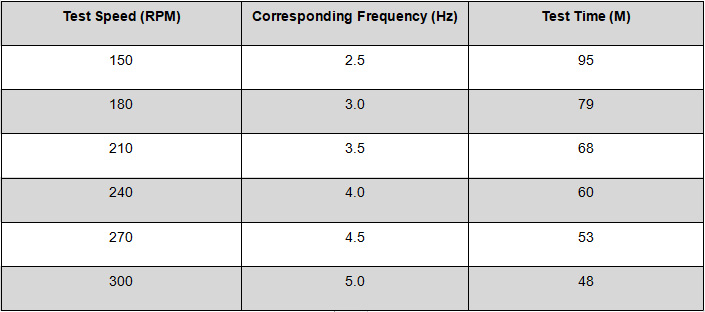

Rotary Vibration Test Machine

- It is used for the vibration tests of ASTM D999, ISTA 1A, or 2A standard.

- It has a vibration table with a fixed amplitude of 25.4mm.

- It only makes rotary motion, and the vibration frequency is adjustable from 1.5Hz to 5Hz.

It is used for non-simulation integrity performance tests. - For the detailed requirements on speed, corresponding frequency, and duration, please refer to the right table.

Random Vibration Test Machine

- This machine is suitable for testing standards of ISTA 2A ASTM D4728 vibration tests.

- It required the overall Grms level of 1.15.

- It is an electromagnetic vibration table. A closed-loop controller can produce desired power spectral density at the table surface adjacent to the test specimen.

- The price is usually higher.

What the Test Procedure of the Rotary Type Vibration Test?

- Place the filled package to be tested in the middle of the work table of the rotary vibration testing equipment.

- Move a pair of parallel guardrails to clamp the carton, and then slide the clamping fixtures on the guardrails to fix the carton.

- Check whether the equipment collides with other objects (there must be a space of 0.5 to 1 meter around the machine).

- Turn the governor knob to the lowest position.

- Connect the power supply specified by the manufacturer and turn on the power button. (At this time, the whole machine is in the standby state).

- Preset the test duration according to requirements of the standard.

- When everything is ready, press the start button to actuate machine and slowly turn the governor to the required speed.

- When the machine runs to the preset time, it will automatically stop and be in standby state.

- After finishing the work, turn off the power switch, take off the sample, and record the test data.

- Organize the machine table and fix the guardrail.

FAQs

The rotary vibration tester has a constant amplitude and is suitable for products with a single package. It is mainly to simulate bumps and vibrations during vehicle transportation to determine the damage to the products. In case of different road conditions such as bumps, uphills, downhills, turns, etc., the product collides with the product in the packaging box, and the product collides with the box, so as to further improve the product quality and product packaging quality.

The vibration of the electromagnetic vibration tester derives from the movement of the energized conductor under the action of electromagnetic force in the magnetic field. An exciting force is generated when the alternating current signal is passing through the moving coil in the magnetic circuit, and a vibration motion is generated in the magnetic circuit at the same time, which is similar to a speaker.

Its cost is much higher than the rotary vibration tester. The electromagnetic vibration tester is suitable for products that require high frequency.

This electromagnetic shaker is used to detect early failures, simulate actual working conditions and structural strength.

- Must use the power supply specified by the manufacturer. It is strictly forbidden to use unmatched voltage.

- When installing the sample to be tested, it must be mounted firmly. Place the package in the center as much as possible. If the sample is found to be unclamped during the test, it should be re-clamped after stopping the machine. Operation is strictly prohibited when the machine is not stopped.

- The bottom area of the carton sample cannot exceed the edges of the work table.

- The weight of the test sample should not exceed the maximum load. If with long-term overload use, It may lead to failure and shortened life of the testing machine.

- Adjust the speed governor to the “0” position before starting to prevent the circuit from burning out. After turning on the power, slowly rotate the frequency adjustment knob to make the table reach the required oscillation frequency.

- This transportation vibration tester is a used to test on the packaging box after the product is packaged. Do not directly perform the product vibration test to avoid scratching and damaging the sample.

- The control box is a power control component and must not bear heavy objects and severe vibration.

- Both the control box and the table have heat dissipation holes, which should not be blocked by any objects and debris.

- When the machine is found to have abnormal sound during operation, immediately stop it for inspection, or contact us for handling before it continue to run.

Don’t worry, we have according solutions for your situation.

Considering the tall packing boxes, for example the refrigerator box with a small base area, but a relatively high height. It is liable to topple and fall in vibration test if fastened by our regular guard rails.

In order to prevent this from happening, we will extend the guard rails to a higher position to match the height of your package and configure with 4 more clamps (8 clamps in total with 2 layers) to hold the carton firmly.

In a word, the height of guard rails can be tailored on the basis of your package height.

Sure, we can tailor a table with the suitable length and width for you to accommodate your package. You just need to tell us the accurate size of your package to be tested when inquiring. Our sales specialist will submit a proposal only fits your requests.

Rotary Motion is a constant elliptical motion trajectory.

The shaking table is attached to the eccentric bearing. When the eccentric bearing rotates under the drive of the motor, the entire plane of the test platform will cyclically move in the upper, front, lower and back directions to draw an elliptical trajectory, which is also similar to the up and down trajectory of a horse’s body when it is running.

When the operator adjusts the speed of the rotary motion, it is equivalent to adjusting the traveling speed of the entire vehicle or ship.

This rotary vibration testing equipment is able to simulate the scenes of the collision or squeezing between products, and between products and the packaging box containing them when the vehicle loaded with goods is subjected to bumping, uphill, downhill, turning or under other road conditions.

There are no strict restrictions on the products in the packaging box, and almost all products can be accepted. But in practical applications, packaging vibration testing is mainly suitable for fragile and easily broken or deformed items, such as pottery, ceramics, LED lights, glass, glass products, computer or mobile phone displays, fruits, eggs, etc. If you are not sure whether it is applicable to your product, you can always “CONTACT US“, our sales specialists are happy to answer any questions from you.

Send an Inquiry

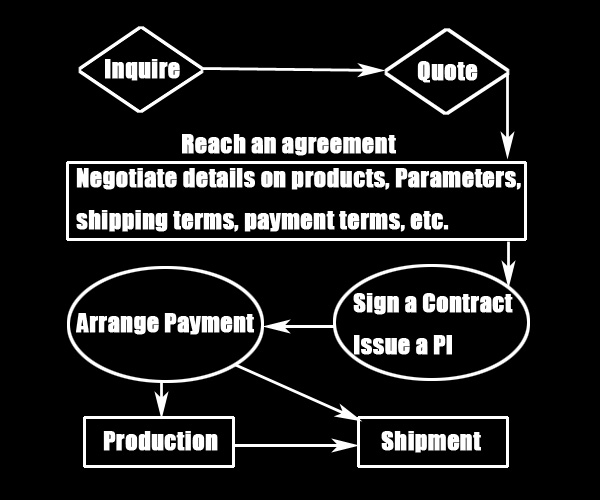

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.