Eyeglass Frame Durability Testing Machine China Supplier and Manufacturer

Spectacle Frame Endurance Tester is intended to determine the fatigue resistance and durability of the spectacle frame by subjecting one temple of the sample to the cyclical rotating movement at a specified speed for a given number of cycles.

It is one of the essential instruments to determine the mechanical stability of spectacle frames.

Spectacle Frame Endurance Test Principle

The nose bridge of the spectacle frame sample is secured on the bridge support. Both temple tips are clamped in the rotating and fixed holders, respectively. One temple mounted in the rotating clamp is driven by the rotating disc through the universal joint to make the angular movement in line with the specified route at a predetermined rate for the specified number of cycles. The distance difference between the specified measurement points on the two temples before and after the test is measured, and the change in appearance and physical characteristics is checked for deformation.

Description for Eyeglass Endurance Tester

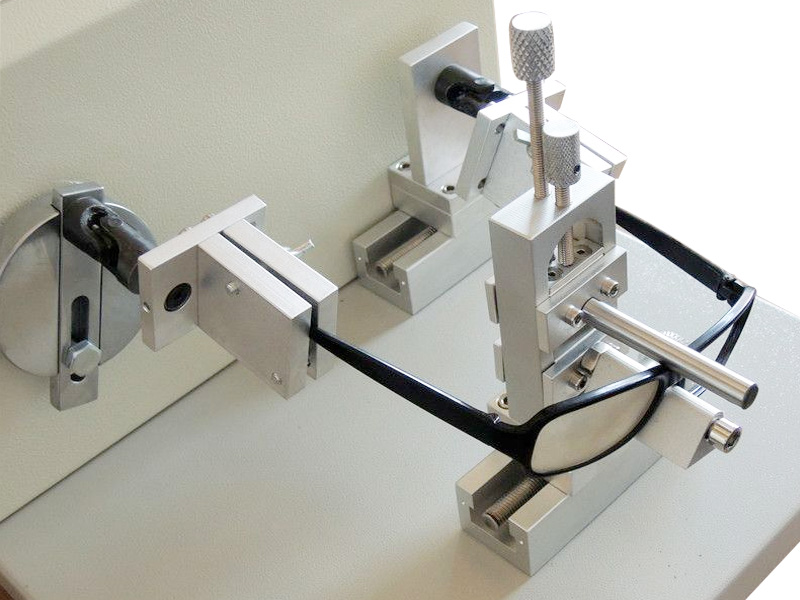

Our Spectacle frame endurance tester comprises two holding devices attached to universal joints, bridge support assembly, control panel, rotating disc, motor, base plate, etc.

Each clamp is made up of 2 flat steel plates brought together by means of 2 butterfly nuts to facilitate tight gripping. Two clamps are mounted on universal joints. When the machine starts, the rotating disc rotated by a motor drives the universal joint to cause one temple on the left to rotate cyclically in a specified route. The right fixed clamp is available to move horizontally to accommodate different sizes of glasses.

The bridge support is a horizontal rod with a triangular cross-section of a specified dimension, which is to simulate the bridge of a human nose to enhance testing reducibility. You are allowed to adjust the bridge support vertically or laterally to be compatible with different samples.

Clamping device

The control panel consists of a LED counter and a few physical buttons. You can feel free to set an intended number of cycles using this digital counter. The preset number and real-time running number will be displayed throughout the test for your monitoring. You are available to set the running speed, suspend and resume the test conveniently by the physical buttons.

For other spectacle frame testing equipment under ISO 12870, please visit HERE.

| Model | AT-DR3002 |

| Counter | 0~9,999, adjustable |

| Rotating speed | 40 cpm, adjustable |

| Dimensions | 28 (W) * 42 (D) * 21 (H) |

| Weight | 28 kg |

| Power supply | 220 V 50Hz / 110 V 60Hz |

- ISO 12870

- ISO 12311

- The compact and lightweight design facilitates moving.

- The fixed clamp and nose bridge positions are movable to accept different sample sizes.

- The rotating speed is adjustable.

- Fitted with an LED display to show real-time data.

- Easy for users to mount and dismount the sample.

- Permits the installation of a protective cover if requried.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.