Outsole Flex Resistance Tester | Sole Bending Tester China Manufacturer

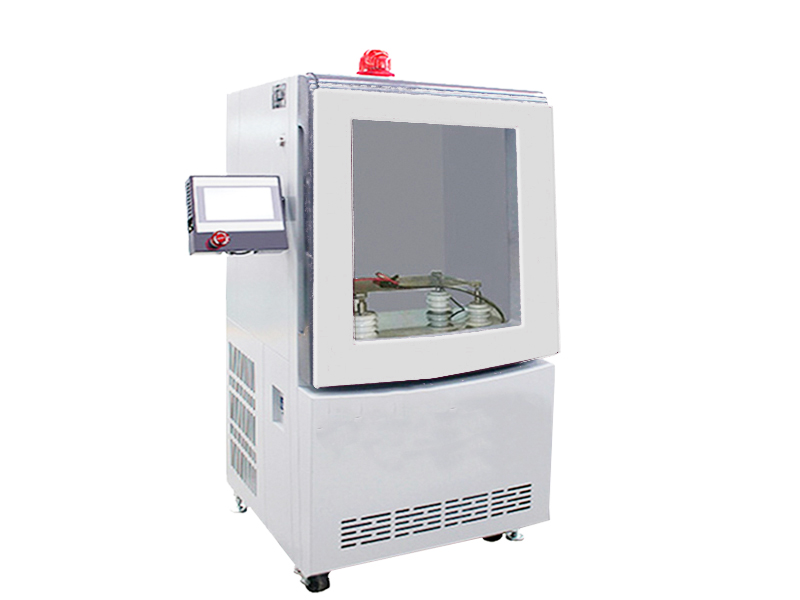

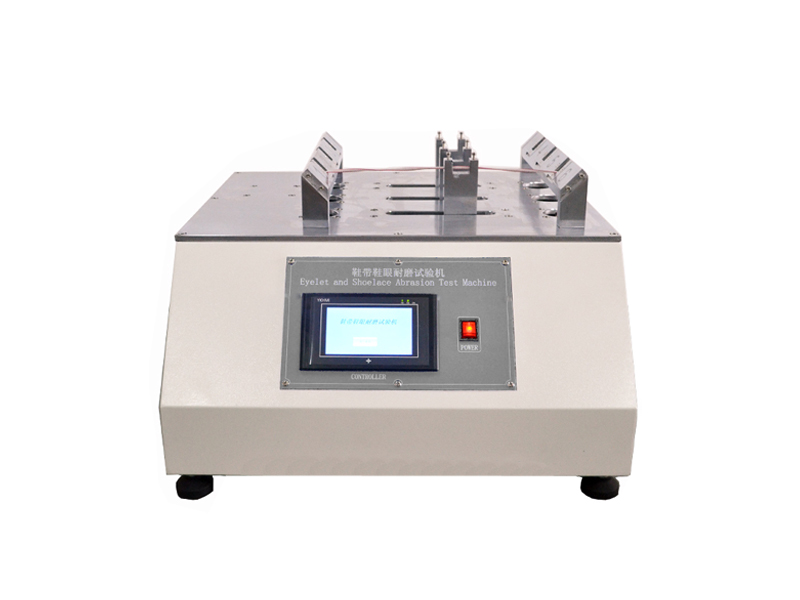

Sole Flexing Tester is also known as the outsole bending tester, which is a footwear testing device intended to determine the resistance of outsole to continuous flexing at 90° angle with a constant bending rate.

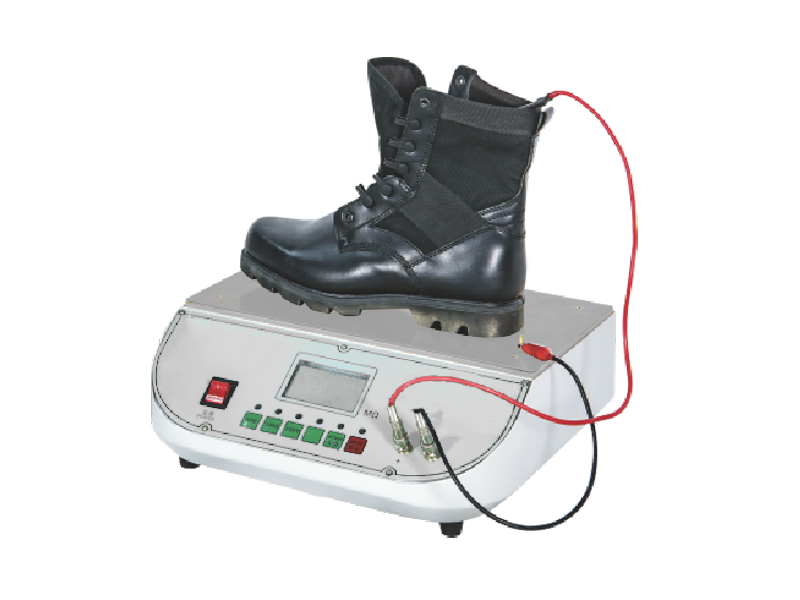

It is widely applicable to a variety of outsoles of footwear. Usually it is used in conjunction with the outsole rigidity tester in the test.

Test Principle

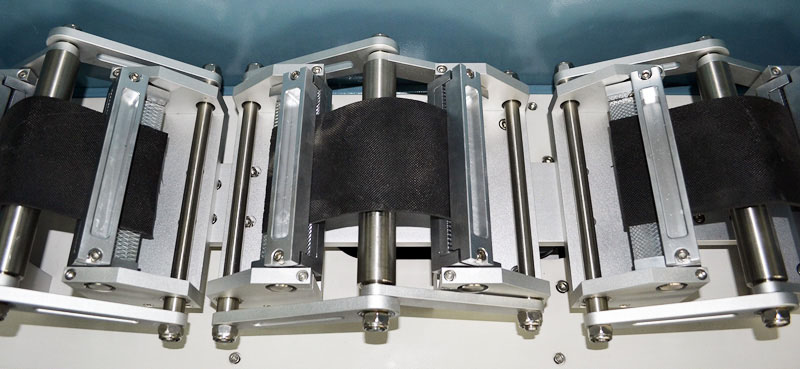

The test piece fastened to the clamps is incised by a cutting tool in the area directly over the center roller when the specimen is in the maximum stretched state. After flexed for specific cycles at a specified speed through a 90-degree angle, the final cut length on the surface of the specimen is measured using a measuring magnifier to compare with the initial cut length before the test to get the cut growth for determining the flexing resistant performance of the test sample.

INQUIRE

Test Standards

- ISO 17707 Footwear-test methods for outsoles-flex resistance

- ISO20344-8.4.2 Personal protective equipment-test methods for footwear-determination of flexing resistance of outsole

- ISO20347-5.8.4 Personal protective equipment-occupational footwear-outsole flexing resistance

- SATRA TM161 Bennewart flex test-resistance to cut growth on flexing

Main Technical Parameters

| Model | AT-F3003 |

| Test Stations | 3 pcs |

| Bending Angle | 90° |

| Mandrel Diameter | φ30 mm |

| Bending Speed | 125 ~ 150 cycles / min (adjustable) |

| Clamp Apart | 110 mm |

| Movable Fixture Stroke | 41.5 mm |

| Width of the Grip | 144 mm |

| Counter | LCD display, 0 ~ 999,999 |

| Dimension | 100 × 53 × 30 cm |

| Net Weight | 93 kg |

| Power | 1 phase, AC 220 V, 3 A |

| Accessories | EN standard cutting tool 1 pc |

Outsole Flex Resistance Tester Features

- Clamps are made of stainless steel to provide enough tenacity and sturdiness.

- The unique clamp design facilitates faster fixing of samples.

- Workstations can accommodate 3pcs soles to be tested at the same time.

- Equipped with a quality motor offers strong power for flexing.

- Digital-display counter supports preset the number of flexes before the test.

- The adjustable bending rate is available from 125cpm to 150cpm.

- The OEM is available.

- Supports operation interface in Chinese&English.

How to Carry Out the Sole Flexing Test

- Prepare the test sample and mark the point on it for later insertion of a cut.

- Mount the test piece on the clamps when the test instrument is in a neutral bending position.

- Pierce the test piece at the point above the mandrel using a cutting tool when the specimen is at maximum flex position, then measure the initial length of the cut.

- Actuate the bending tester to conduct the test for 30,000 cycles at a constant speed between 135 cycles /min and 150 cycles/min.

- At completion of given cycles, measure the latest length of the cut again and minus the length of the cut before the test to get the cut growth.

The above is just a reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.