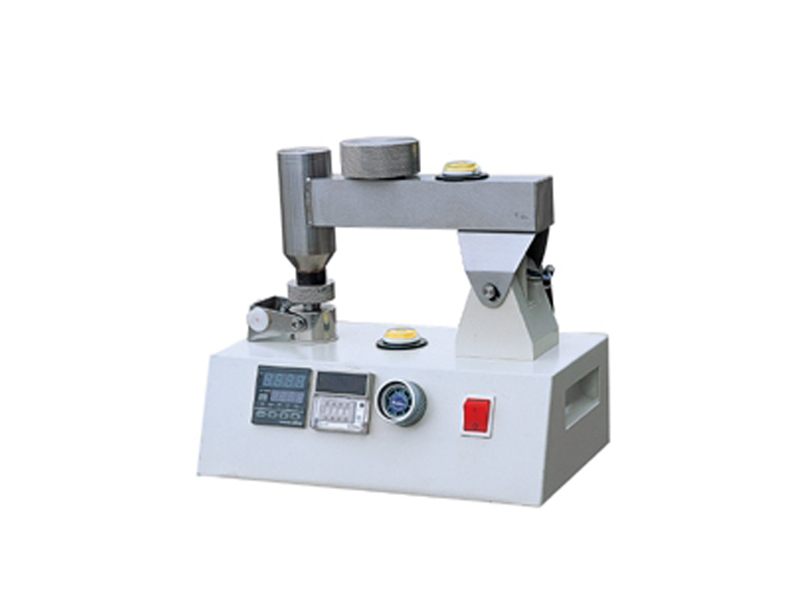

Finished Shoes Bending Tester China Manufacturer

The Completed Footwear Flexing Tester is intended to evaluate the resistance of final shoes to repetitive flexing and cracking. The machine is designed strictly in accordance with relevant standard, and it can help footwear makers adjust and improve the quality of products. This Footwear Tester is suitable for all types of footwear, including sneakers, casual shoes, occupational shoes, other finished shoes, etc.

Principle of Footwear Flexing Resistance Testing Machine

The finished shoe sample is mounted in the grips which can make the reciprocating motion, and continuously bent about the natural flexing line at a constant speed through a specified angle. The flexing action is completed once either preset flexing time or the number of flexes is reached. The sample is inspected for damage and the flex-resistant ability is determined.

Test Standard

SATRA TM92

Main Technical Parameters

| Model No. | AT-F3002 |

| Specimen Stations | 4 pcs or 2 pcs optional

Shoe size: for Children: 4 ~ 13 | for Men or Women: 1 ~ 12 (UK size) |

| Flexing Angle | 10° ~ 90° (adjustable), Normal: 30°, 45°, 60°, 90° |

| Test Speed | 50 ~ 150 r / min (standard)

Speed and Angle comparison table 60 ~ 300 r / m (Flexing angle 0° ~ 15°) 60 ~ 200 r / m(Flexing angle 0° ~ 50°) 60 ~ 140 r / m(Flexing angle 0° ~ 60°) 60 ~ 100 r / m (Flexing angle 0° ~ 90°) |

| Specimen Length/Width | Length: 150 mm ~ 400 mm

Width: 150 mm (max.) |

| Counter | LCD display, 0 ~ 999,999 |

| Motor | DC 1/2 HP |

Shoes Flexing Tester Features

- Made of precision stainless steel to cause this flexing machine to be sturdy and durable.

- Touch screen or Digital display + button control available.

- Specimens are easy to be mounted and dismounted from the grips.

- The humanized design ensures that the testing machine to be easy to operate.

- With a minimum wear and noise level during the work.

- The stations can accommodate two shoes or four shoes(2 pairs of finished shoes) to be tested each time.

- The testing speed can be adjusted according to the test angle.

- The machine is steady and smooth while running, owing to the vibration offset design and quakeproof feet.

- Fitted with acrylic-made clear lid to cover the specimens to protect operators during the test.

How to Use The Shoes Flexing Tester

- Position the flexing line (draw a line along the length of the insole starting from the mid-point of the toecap and ending at the mid-point of the heel, and measure the distance of this line from the heel end to the direction of the toecap end based on the value specified on SATRA TM92 to find and mark the flexing point, then retreat 5 ± 1mm to heel direction down the longitudinal line to locate a point, draw the second line across this point perpendicular to the first long line, this line is referred as Flexing line).

- Set a flexing angle and speed at 140 ± 10 cpm under the relevant specification.

- Mount one shoe or a pair in the clamps of flexing testers firmly, then start the machine.

- Suspend the tester and Inspect whether shoes are held tightly by the grips after 500 cycles.

- Stop the machine, check and evaluate the damage to the specimens after the required inspection stage reaches.

- Record all types of damage at each inspection stage. Testing is completed If the shoe has failed or has been subjected to prescribed flexing cycles.

(The above is a brief intruduction of the procedure. Please refer to the SATRA TM92 standard for more details. )

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.