Scott-type Internal Bond Strength Tester for Paper and Boards

Scott Bond Tester is intended to determine the internal bond strength of a sheet of paper or board. It enables measuring the energy required to rapidly delaminate materials by a pendulum in the “Z” or thickness direction at a specified rate.

The tester fits single and multi-layer papers and boards, including coated sheets and those laminated with synthetic polymer films. Samples with low grammage, pores, low density, or high softness are not recommended to be tested with this machine.

The internal bond strength tester has a pendulum of the given mass with a metal striker ball at its free end, which is free to rotate from a horizontal level over at least 180 degrees.

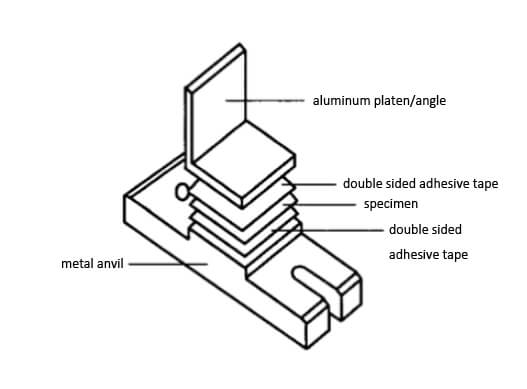

A square test piece in 25.4 mm x 25.4 mm requires to be sandwiched between 2 layers of double-sided adhesive tape. Its upper side and lower side are tightly adhered to an L-shaped aluminum platen and a rigid metal anvil, forming a test assembly.

You need to secure the test assembly in the defined position to allow the pendulum to deliver a strike on the inside face of the aluminum platen after pressing the release switch. The energy in J/m2 (internal bond strength value) absorbed can be displayed on the digital screen immediately after each strike. The maximum measurable delamination energy this machine can determine is as high as 1000 J/m2. You are available to print the test results by means of the in-built thermal printer on-site.

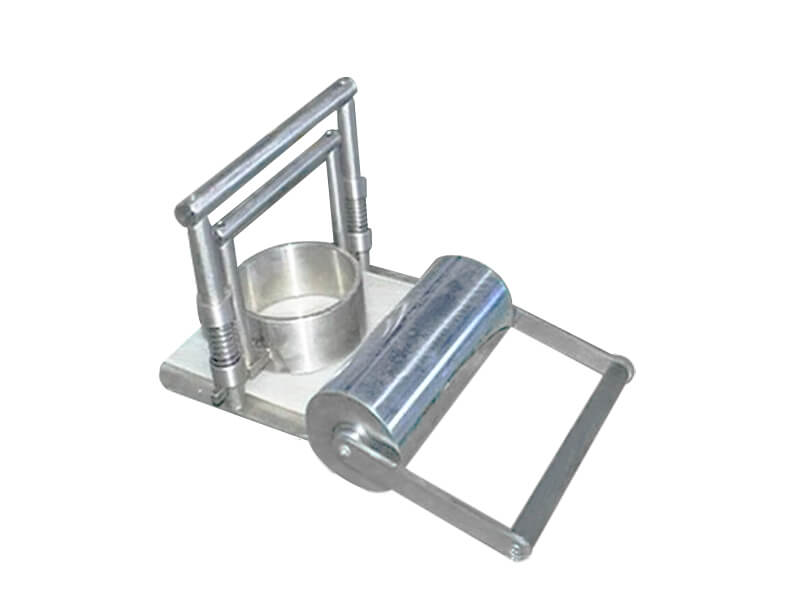

In order to facilitate preparing samples, this Scott bond tester is equipped with a sample preparation station to allow you to make 5 test assemblies at a time. It consists of various stationary and separable metal components. A roll of adhesive tape of 25.4 mm in width can be hung erectly on a rotatable axle to be pulled out conveniently during the preparation as per needs. You can pull the lever handle to apply a pressure of (690±20) kPa to each assembly for a specified period of time to achieve enough adhesion. Our new equipment has the function of one-button pressurization by pneumatic or hydraulic means, instead of manual operation to take action on the sample assemblies.

Compliant Test Standards

- ISO 16260

- TAPPI T 569 om-22

- TAPPI T 833 pm-94

- GB/T 26203-2010

- ASTM T569 pm-00

- TAPPI- UM403

Main Technical Parameters

| Model | AT-P8037 |

| Specimen size | 25.4 mm × 25.4 mm |

| Control mode | Push-button or Touch screen (selectable) |

| Test capacity | Gear A: 20 ~ 500 J/m2, Gear B: 500 ~ 1000 J/m2 |

| Resolution | 0.1 J/m2 |

| Indication error | Gear A: ± 1 J/m2 , Gear B: ± 2 J/m2 |

| Units | J/m2, lbf/in2 interchangeable |

| Dimensions | 530 mm x 430 mm x 730 mm |

| Weight | 65 kg |

| Power supply | AC 220 V / 110 V, 50/60Hz |

Internal Bond Strength Tester Features

- Completely consistent with relevant standards and user-friendly.

- Made of rigid metal to achieve exceptional structure strength to avoid energy loss caused by vibration during the test.

- The control panel is available in button type or touch-control type.

- Provided with a complete set of sample preparation devices.

- Controlled by a microprocessor, with test data statistical processing function.

- Fitted with an LCD to exhibit parameters.

- Test results can be printed out with a built-in printer.

- One button operation to pressurize the test assembly.

- Either pneumatic or hydraulic pressurization method to clamp the test assemblies, whose pressure can be adjusted.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.