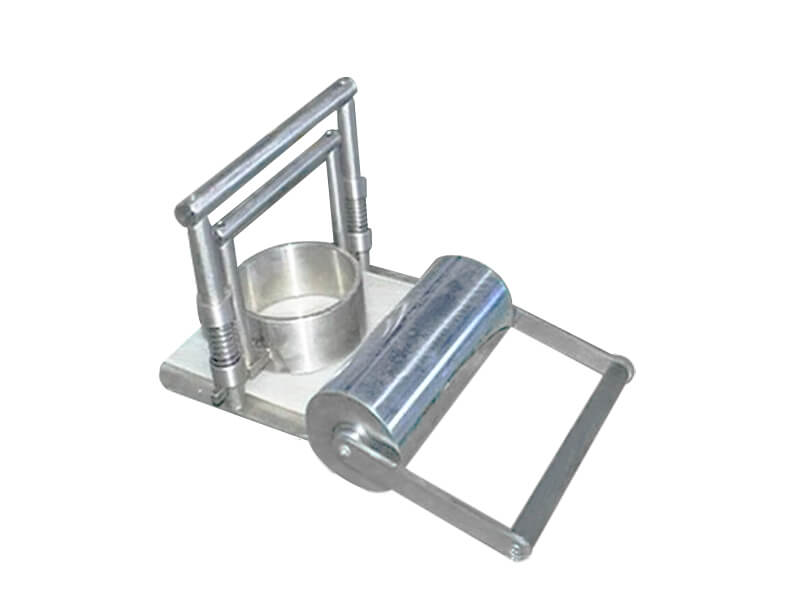

Folding Apparatus (Schopper Type) Supplier

Schopper-type Folding Endurance Tester is a testing machine used to measure the folding resistance of papers having a thickness of 0.25 mm (0.01 in.) or less and a tensile strength greater than 1.33 kN/m or cardboard with a thickness of 0.25 mm to 1.4 mm.

Special papers such as book cover paper, writing paper, drawing paper, and envelope paper are usually required to be tested with the Schopper type folding method. It is also suitable for the folding endurance test of metal foil, aluminum foils, and plastic films.

Conforming Test Standards

- ISO 5626

- TAPPI-T423PM

- ASTM-D2176

- SCAN P 17:77

- TAPPI T 423/453

- TAPPI T453/511

- JIS-P8115

- SJ/T11140

- GB/T457-2008

Main Technical Parameters

| Model | AT-P8036 |

| Sample thickness | Paper sample (0.01 ~ 0.25 mm in thickness, and the tensile strength is greater than 1.33kN/m),

Cardboard (0.25 ~ 1.4 mm in thickness) |

| Distance between clamp heads in each pair | 90 ± 0.5 mm |

| Creasing roller dimension | 6 mm in diameter, 18 mm in length |

| distance between the folding blade and the creasing roller | 0.3 mm |

| The width between the roller and the unbent test piece | 0.5 mm |

| Folding blade thickness | 0.5 mm |

| width of the slot in the blade | 0.5 mm |

| Spring tension | 4.91 N, 7.55 N, 9.81 N, 14.72 N adjustable |

| Folding speed | 110 ~ 120 RPM |

| Sample width | 15 mm |

| Counter | 0 ~ 99,999 |

| Power supply | 1 phase, AC 220 V, 50 / 60 Hz or specified |

What is Schopper Type Folding Endurance Tester?

The folding endurance tester (Schopper type) is specially used to test the folding endurance of paper and paperboard. It contains a pair of horizontal clamps for holding the sample, 4 creasing rollers, and a folding blade. The jaw distance between the two clamps assortative horizontally is 90 mm, and the folding blade is located in the middle of the two jaws.

During the folding test, the tension of the spring is constantly changing. For paper with a thickness of less than 0.25mm, when the sample is straight, the tension applied by the spring is 9.8 N ± 0.2 N. When the folding blade runs to the limit position, the paper strip is folded to its maximum, and the tension applied by the spring is 12.75 N ± 0.20 N.

A motor drives the movement of the folding blade, and the movement stroke is 20mm.

The counter records the number of folds, and it stops automatically when the paper strip breaks.

What is the Paper Folding Endurance Test Procedure with the Schopper Type Folding Apparatus?

- Adjust the Schopper folding endurance tester to the horizontal state.

- Start the machine and adjust the gap between the folding blades to the center of the 4 folding rollers to ensure that the installed paper strip is exactly in a straight line and the slotted folding blade reciprocates in a vertical plane at right angles to the test piece through the point midway between the clamps.

- Tighten the screws of both ends of two clamps of the paper strip to ensure that the sample does not slide, and pull the spring barrel until the pin locks the spring barrel to apply tension to the sample.

- Start the test, allowing the sample to be folded until it is broken, and record the number of double folds when the sample breaks.

What’s the Difference Between MIT Folding Endurance Tester and Schopper Folding Endurance Tester?

- They have different thickness applications in paper or paperboard samples. MIT folding endurance tester is used to test paper or paperboard with a thickness between 0.25 and 1.25 mm. The Schopper-type tester is used to test paper samples with thicknesses less than or equal to 0.25 mm and tension greater than 1.33 kN / m.

- The method of testing is also different. The MIT folding endurance tester uses a clamping head whose gaps can be replaced to clamp the paper strip firmly, and the head can rotate back and forth by 135°. The other end of the paper strip is clamped by adjustable spring tension jaws. The oscillating head starts to fold the specimen until it breaks. The Schopper folding endurance tester uses a pair of spring clamps that are in a straight position to clamp the two ends of the paper sample and apply tension to the two ends of the paper strip. The blade installed in the center of the folding roller repeatedly folds in the direction perpendicular to the paper strip until it breaks.

Request a Quote

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.