Salt Fog (Mist) Test Chamber Supplier

The salt(fog) spray chamber is designed to evaluate the corrosion resistance of metallic materials and coatings by simulating harsh saline environments. It is widely used in automotive, aerospace, and electronics industries to help in determining product durability and stability.

Our salt fog test chambers are capable of performing the neutral salt spray (NSS) test, acetic acid salt spray (AASS) test and copper-accelerated acetic acid salt spray (CASS) test. And the test results have excellent reproducibility and repeatability.

A salt spray test machine consists of a fog cabinet, a saturation tower, atomizer towers, atomizing nozzles, a salt solution reservoir, fog collectors, sample supports, a control panel and other essential components.

Fog Cabinet

The cabinet is made of reinforced Polypropylene Random Copolymer(PPR), offering exceptional resistance to acidic and saline corrosion. A double-wall insulation design maintains thermal stability. The cabinet’s cover is constructed with two sloping ceilings to allow the drops of sprayed solution formed at the top to slide down the slops to the sides and avoid them falling naturally down to the specimens throughout the test.

There is a heating element immersed in the water at the bottom of the inner cabinet to maintain the cabinet and its contents at the specified temperature, and you are available to freely adjust the cabinet temperature. The top edge of the cabinet is designed with a U-shaped aqueduct, which needs to be filled with water to form a water seal when the lid is closed to prevent salt fog from overflowing to the outside of the cabinet during testing. Different capacities of cabinets such as 60L, 90L, 120L, 160L are available for users to choose.

Saturation Tower

In order to prevent the evaporation of water from the sprayed droplets, a saturation tower is equipped inside the device to allow the air to be humidified by passing through it before entering the atomizer. In addition, the water in the saturation tower needs to be heated to offset the cooling effect of expansion to atmospheric pressure during the atomization process. The water temperature varies depending on different compressed air supply pressures. Our machines allow you to freely adjust the saturation tower water temperature to the desired value. There is an automatic water replenishment function when the water level is too low.

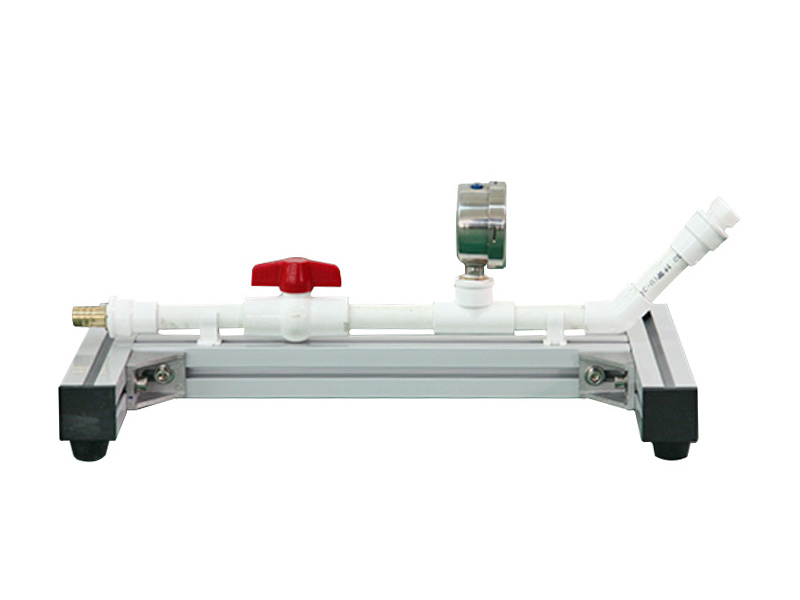

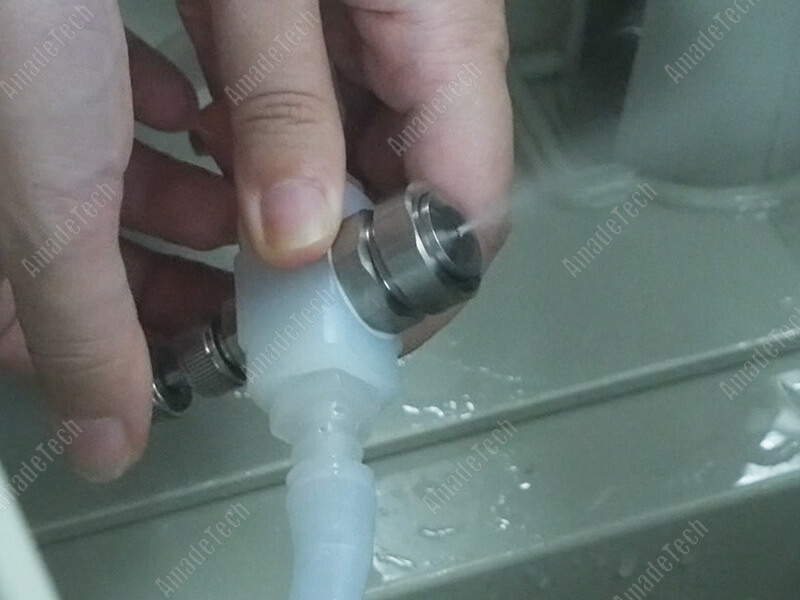

Spray Nozzle & Atomizer Tower

Unlike other people’s traditional spray nozzles made of crystal, our salt mist chamber adopts precision-machined titanium spray nozzles. It is characterized by corrosion resistance and long service life. The key is that it allows you to adjust the size of the atomization according to your testing needs by turning the knob at the bottom, which is not possible with traditional nozzles.

Spray nozzle

Atomizer tower

The atomizing nozzle is positioned at the bottom of a vertical hollow circular tube to spray upwards. A cap is fitted at the top of the tube to prevent the salt spray from being directed onto the lid of the cabinet, and an inverted cone at the bottom of the cap guides the upward mist to spread horizontally in all directions. The cap can be adjusted up or down to help in obtaining uniform distribution of the mist within the cabinet.

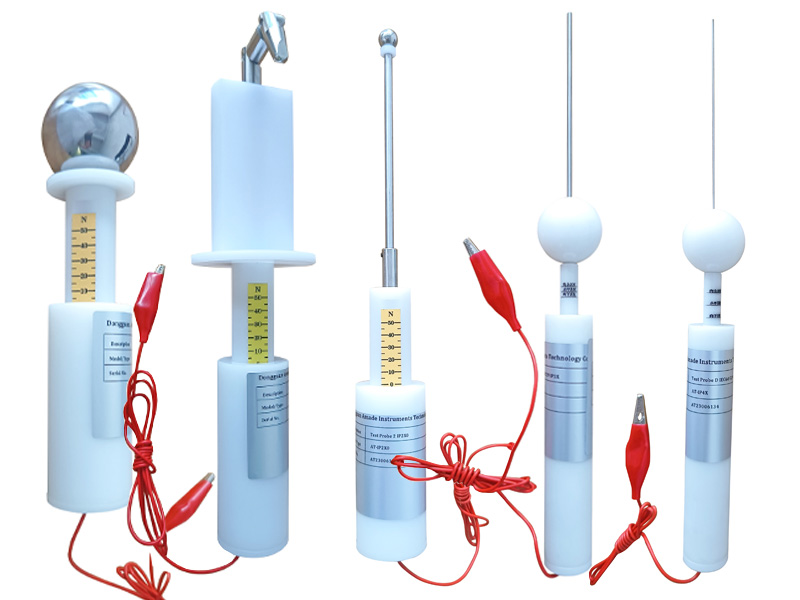

Fog Collectors

Two fog collectors are rationed to one atomizer tower to check the the homogeneity of the spraying of the cabinet. One is close to an tower, and the other is remote from an tower, ensuring no liquid falling from the sample or from parts of the cabinet is collected.

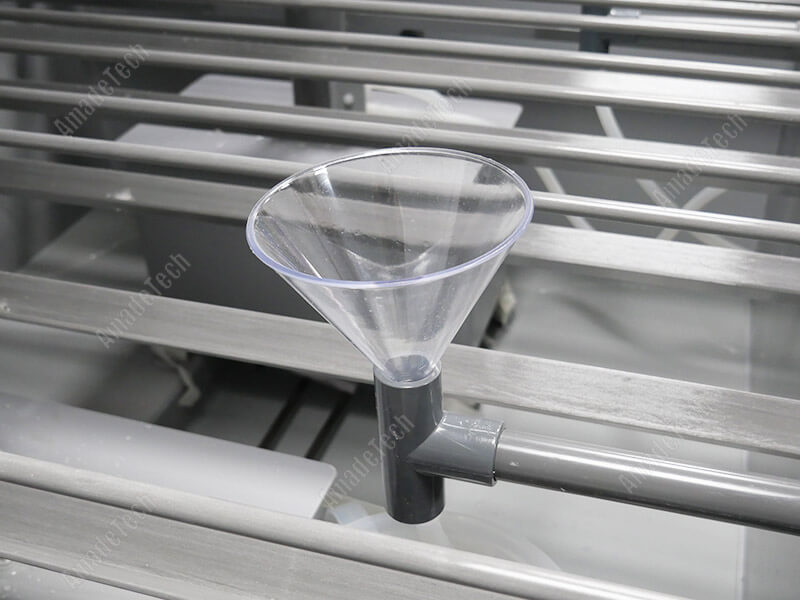

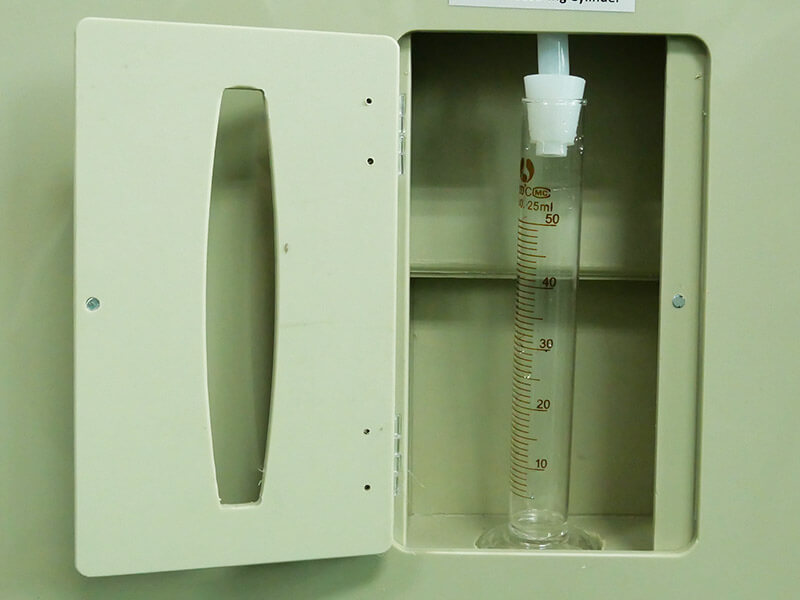

Funnel

Cylinder

The fog collector consists of a funnel with a diameter of 10 cm and a collection area of approximately 80 cm2 , connecting hose, measuring cylinder with volume scale. In order to allow the operator to keep an eye on the amount of fog collected, the measuring cylinder has been designed to be located directly in the front of the salt spray cabinet.

Sample Supports

The sample holding device for our salt spray chambers consists of removable V-shaped racks and rods made of synthetic fibre. The bottom row of V-racks is used to hold the test specimen and the upper row of rods is used to support and tilt the test specimen to ensure that the test specimen placed on the rack facing upwards is at an angle as close as possible to 20° to the vertical. You can also flexibly adjust the spacing of the support devices according to your testing needs and the size and shape of the specimen.

Sample arrangement

Control Panel

We offer two types of control panels for you to choose from: a push-button control panel and a PLC 7-inch touch screen. The Push-button screen allows you to set and give test commands by pressing physical buttons. It is equipped with a variety of water level alarm indicators, and automatically shuts down when the test time is reached.

Push-button control panel

Touch screen control panel

All control operations on the touch screen are accomplished by tapping the corresponding virtual icons on the screen with your finger. In addition to this, it also supports intermittent cyclic test mode, i.e. a spray time period and a stop time period are preset, and the unit cycles through the two time periods alternately.

Compound Fog Spray Chambers

AmadeTech is also able to offer advanced compound salt spray chambers in different sizes. In addition to all the features of a traditional salt spray tester, they also have temperature and humidity regulation to simulate the alternating conditions of temperature, humidity and heat.

Compound salt spray chambers are more complex in structure, in addition to containing all the components of the traditional salt spray test chambers, but also increased temperature and humidity control components, such as compressors for controlling low temperature. As a result, its function is also more powerful, it is equivalent to a constant temperature and humidity chamber and a salt spray test chamber of the combined body.

The compound salt spray test chamber is suitable for testing various performance indicators of samples under alternating compound conditions such as high temperature, dampness and heat, dryness, and salt spray.

Compound salt spray chamber

Test Principle

Salt solution of specified composition and proportion is uniformly sprayed onto the surface of the test specimen inside the fog chamber through compressed air atomization under specified temperature conditions. The test specimens are inspected frequently or after recommended exposure periods. By maintaining precise pH (6.5~7.2), temperature, and spray settlement rates (1~2ml/hr/80cm²), the system replicates years of environmental exposure within days. Advanced models incorporate cyclic modes to simulate alternating cold/wet/dry phases, mimicking real-world coastal or industrial atmospheres.

Test Standards

- ASTM B117 Standard practice for operating salt spray (fog) apparatus

- JIS H8502 Methods of corrosion resistance test for metallic coatings

- IEC68-2-11 Basic environmental testing procedures – salt spray test

- IEC68-2-52 Environmental testing – salt spray test cyclic (Sodium chloride solution)

- ISO 9227 Corrosion tests in artificial atmospheres – salt spray tests

- GB/T 2423.17-1993 salt spray test

- GB/T 2423.18-2000 salt spray test

- GB/T 10125-1997 salt spray test

- GB.10587-89 salt spray test

- CNS.4158 salt spray test

- CNS.4159 CASS Accelerated acetic acid copper salt spray test

- GB/T 12967.3-91 CASS Accelerated acetic acid copper salt spray test

Technical Parameters

| Model | AT-C1008-60 | AT-C1008-90 | AT-C1008-120 | AT-C1008-160 |

| Interior dimension(L×W×H) | 60×45×40 cm | 90×60×50 cm | 120×80×50 cm | 160×100×50 cm |

| Volume of spray | 1-2ml/80cm²/h

(Average collection rate for a horizontal collecting area of 80cm²) |

|||

| Heating system | Titanium alloy electric heating tube, more corrosion resistant | |||

| Salt mist collecting device | 2 pieces of funnel shaped salt mist collectors | |||

| Spray mode | Continuous spraying

Intermittent spray |

|||

| Spray pressure | 0.1 Mpa | |||

| Salt spray test type | NSS, AASS, CASS | |||

| PH value | NSS: 6.5~7.2 ;

CASS AASS: 3.1~3.3 |

|||

| Test chamber temperature | (35±1)℃ (NSS, AASS) | |||

| (50±1)℃ (CASS) | ||||

| Saturation tower temperature | (47±1)℃ (NSS, AASS) | |||

| (63±1)℃ (CASS) | ||||

| Power supply | 1 phase 220V, 50Hz / 110 V, 60 Hz | |||

Salt Spray Cabinet Features

- The fog cabinet is constructed from corrosion resistant PPR material.

- The lid is available in transparent or opaque colors.

- Ramp design of the cover avoids accumulated drops of liquid on the ceiling of the cabinet.

- A water seal is available to isolate the fog area from the outside environment.

- Saturation tower and cabinet tank with automatic water refill function.

- The cabinet has a defogging function.

- The spray volume of the nozzle can be adjusted.

- Equipped with special sample supports in the exposure zone.

- Push-button control panel or 7” touch screen control panel available.

- Supports continuous spray or intermittent spray if required.

- Fitted with various safety protection devices such as water shortage, salt solution shortage, electric shortage, etc.

- Various sizes of cabinets are available from AmadeTech.

- Advanced models with compound test environments are available.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.