Protective Shoes Insulation Against Cold Test Chamber China Manufacturer

Shoe Cold Insulation Tester is a commonly used footwear testing machine intended for the determination of the flexing resistance or elasticity resistance of materials such as finished shoes, upper leather, shoe soles, leather, synthetic leather, textile, rubber, etc. at low temperatures to understand how the materials or finished products adapt to low-temperature climates or cold regions.

Test Principle

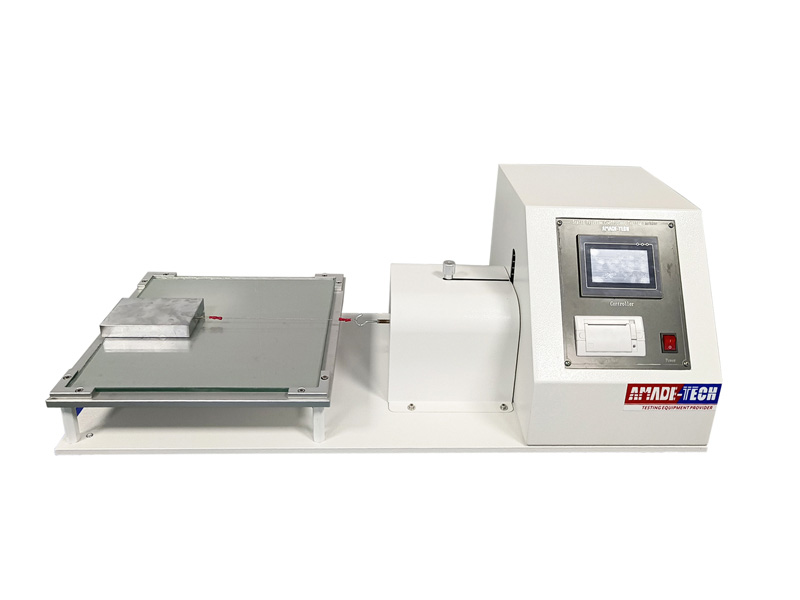

The shoe sample filled with steel balls as a thermal transfer medium is placed on a copper plate inside the cold box keeping the constant temperature at -17℃. The upper top opening is carefully closed with a suitable plug. The temperature probe is fixed to the insole or insock. The temperature on the insole or insock right after placing the test piece in the chamber and after 30 more minutes is measured using the temperature measuring device connected to the temperature probe. The temperature decrease measured during the 30 minute period of cooling is reported.

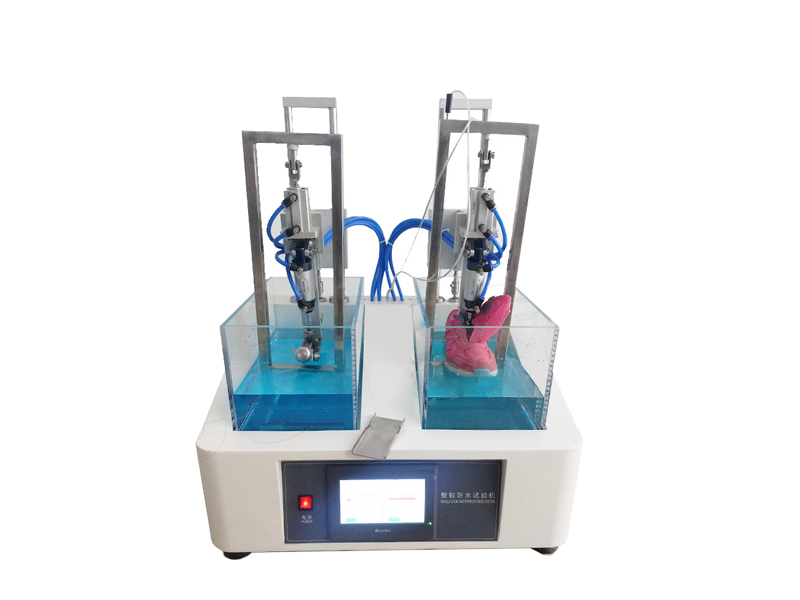

This low-temperature test chamber also can be installed with different flexing apparatuses for the tests of Bally flexing, Vamp (Upper) flexing, Ross flexing, etc.

Test Standards

EN ISO 20344 5.13, GB/T 20991, AS/NZS 2210.2 Determination of insulation against cold

INQUIRE

Main Technical Parameters

| Model | AT-F3005 |

| Test Chamber’s Temperature Control | RT ~ -20 ℃, RT ~ -30 ℃ or RT ~ -50 ℃ (Optional) |

| Copper Plate | Dimension: L 350 mm x W 150 mm, Thickness: 5 mm |

| Thermal Transfer Medium | Stainless steel balls: diameter 5 mm, total mass: (4000 ± 40) g |

| Temperature Probe | Accuracy: ± 0.5℃, soldered to a copper disc of (2 ± 0.1) mm thick, diameter (15 ± 1) mm |

| Temperature Measuring Device | Connected to the temperature probe |

| Standard Accessories | Temperature probe 1 pc

5 mm diameter steel balls 4 kg Temperature measuring device 1 pc |

| Optional accessories | Bally flexing Jig, Vamp (Upper) flexing jig, Ross flexing jig or specified |

Features of Shoes Cold Insulation Test Chamber

- Amade’s low-temperature test chamber is stable and durable, and the refrigeration compressor and essential electrical parts are all internationally renowned brands.

- Powerful refrigeration ability to satisfy the low-temperature requirement throughout the test.

- The inner test box and main parts are made of stainless steel, which is durable and reliable.

- Multiple protection devices such as leakage protection, over-temperature protection, reverse-phase protector are available to ensure the safety of the machine and the operator during the test.

- Other more fixtures can be equipped in the chamber according to the test requirements to achieve versatile functionalities.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.