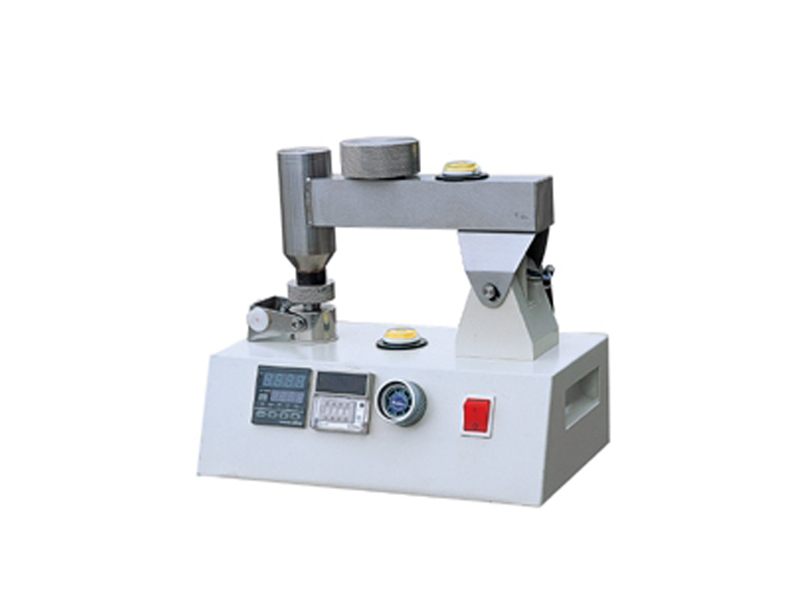

Safety Shoes Impact Tester China Manufacturer

Safety Shoe Impact Tester is the Footwear Testing Device intended for the determination of impact resistance of safety shoe’s toecap under specified conditions.

The test piece is the forepart of the footwear by cutting off the toe end 30 mm behind the rear edge of the toecap. A cylinder is positioned on one of its ends inside the test piece. The specimen is placed and secured in the directed place of the testing machine to make sure the striker is capable of hitting the back and the front of the toecap. The striker is elevated slowly to the appropriate height and then released to blow the test piece to deliver impact energy. The lowest height to which the cylinder has been compressed is measured with a dial gauge to evaluate the impact resistance.

This safety shoe tester is designed on the basis of EN, ANSI, BS, CAS standards, using 100J or 200J as kinetic energy to strike the toecap of safety footwear. Due to the difference among the various standards, please remember to clarify the specific standard to be applied when asking for a quotation.

Test Standards

- EN ISO 20344 section 5.4 & 5.16

- AS/NZS 2210.2 Section 5.4 & 5.16

- CSA-Z195 Section 5.21

- ANSI-Z41 Section 1.1.5

- ASTM F2412 Section 5

- ASTM F2413 Section 5.1

- GB/T 20991-2007

Main Technical Parameters

| Model | AT-F3010 |

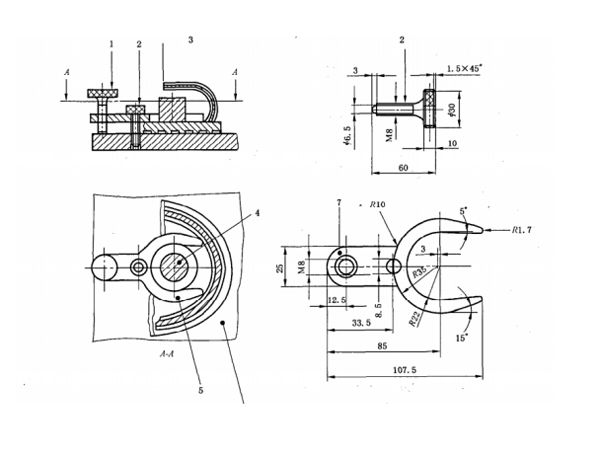

| Impact Striker | EN 12568, ISO 20344

Mass of (20 ± 0.2) kg, made of steel Rockwell hardness: 60 HRC Wedge: at least 60 mm long, at 40 mm in height Corner radius R3 mm Angle: (90 ± 1)°

|

| Cylinder of Modelling Clay | EN 12568 Dia: (25 ± 2) mm, height: (28 ± 2) mm ≤ size 5, Height: (30 ± 2) mm ﹥size 5

ISO 20344 Dia: (25 ± 2) mm, height: (20 ± 2) mm ≤ size 40, Height: (25 ± 2)mm ﹥size 40 ANSI-Z41 Dia: 25.4 mm |

| Impact Height | 0 ~ 1100 mm adjustable |

| Impact Energy | 200 J, 100 J |

| Standard Accessories | Toecap clamp device 1 set

Power line 1 pc |

| Optional Accessories | Metatarsal protective test clamp device for ISO 20344 – 5.16 |

Safety Shoes Impact Tester Features

- Amade safety shoes impact tester’s unique design can prevent the second impact on the sample after the first blow.

- Lift the impact head with one key: After setting the impact height, you press the lift button on the controller, and the striker will be raised to the preset height.

- For operator safety, the controller and the safety shoe impact tester are separate.

- To prevent the operator from being hurt by splashing fragments from the test sample, a guardrail was installed at the bottom of the test device.

- AMADE can customize the impact device according to the customer’s test requirements.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.