Laboratory-type Hydraulic Platen Vulcanizing Press Rubber Machine China Manufacturer and Supplier

Rubber Plate Vulcanizing Press Machine provides the pressure, temperature and time control required for vulcanization to press and shape various molded and non-molded rubber and plastic polymer sheet materials for further testing or as a mass production basis.

The vulcanizing press machine is mainly suitable for formula design of rubber and plastics, heat and pressure vulcanization treatment of common rubber materials, preparation of simple rubber vulcanized products, preparation of simple thermosetting material products, thermocompression moulding of common rubber plastics and composite materials, research on the vulcanization process of common rubber materials and rubber vulcanization process parameter optimization and control.

Rubber Plate Vulcanizing Press Machine Working Principle

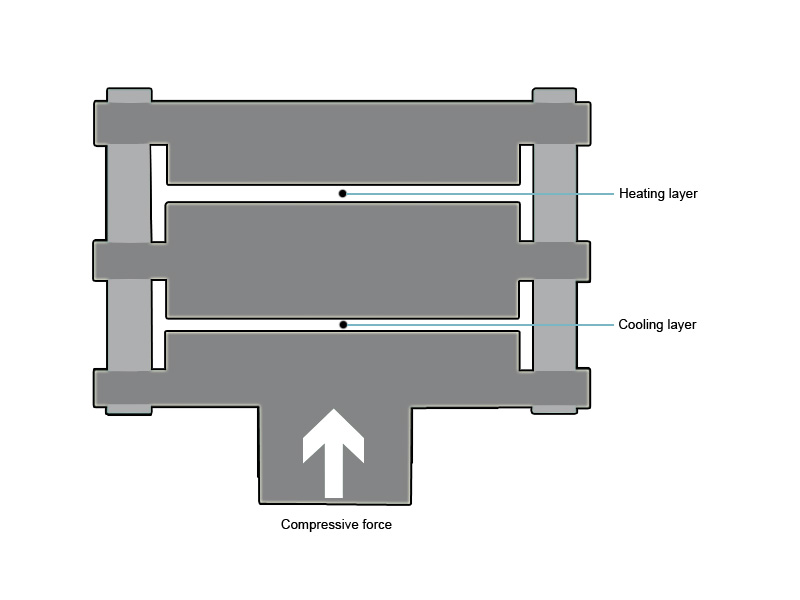

The rubber material placed in the mold is clamped between two flat plates heated to a specified temperature. The predetermined pressure between two plates is applied to the rubber material for a specified period of time by means of a set of the hydraulic system. After high temperature and high pressure, the vulcanization is completed and the material is pressed into the desired shape.

Description on the Plate Vulcanizing Machine from AMADE TECH

Our vulcanizing press adopts a four-column structure. Four high-precision guide pillars have strong load capacity, stable lifting and excellent wear resistance. There are upper and lower working areas made of 4 pieces of KDB solid high-carbon steel, which have the characteristics of high-temperature resistance, corrosion resistance, fast heat conduction and no deformation. Each plate is parallel to the other, has the same contact area, and remains aligned longitudinally.

The upper layer is a heating layer with a built-in heating tube and a high-precision temperature sensor, which can heat-press and melt the material. Its temperature range is from room temperature to 300°C. Equipped with P.I.D self-tuning mode and a high-precision sensor, it has an automatic temperature compensation function to ensure temperature balance. The lower layer is the cooling layer. It allows water circulation inside the plates, which can simultaneously cool and shape the material. The sheet material is available to be cooled immediately after hot pressing, which improves the test effect and work efficiency.

Pressing plates

The bottom plate is connected to the piston rod of the hydraulic system. When the hydraulic system is working, the piston rod moves up and down up to 180 mm under control to bring about the up-and-down displacement of the plate to control the opening and closing of the heating layer and cooling layer as required. Our pneumatic vulcanizing press machine is equipped with a high-performance oil pressure system, with a high-precision oil cylinder and oil pressure sensor. The system has the function of automatic pressure compensation. You can preset the time and pressure of primary and secondary pressurization. The machine can automatically pressurize and depressurize during work. There are various pressure ranges available for you to choose from, and the maximum support is 100 tons. You can customize the vulcanizer press machines of different maximum pressures according to your material properties.

Button control vulcanizing press

Our plate vulcanizing presses support traditional button control and PLC touchscreen control. The button control panel consists of different keys, switches, meters and digital screens. Its operation interface layout is reasonable and easy to use. All triggering devices are marked with corresponding functions below. Real-time information such as temperature, current, oil pressure, and time can be displayed on the corresponding electronic screen or meter in real-time. The button controller can help you save purchase costs while providing intuitive operation.

PLC programmable colour touchscreen control applies the most cutting-edge industrial technology. The real-time data of various command switches and monitoring data are integrated into this high-definition display screen. You can see the dynamics of the molding process, temperature, pre-pressing time, and pressurizing time, and you can easily adjust the pressure, set the pressure and control the heating program by touch. The flat plates can realize fully automatic rising and falling. The PLC control further improves the convenience of operation and allows the control module to achieve more functions.

Main Technical Parameters

| Model | AT-R7026-X |

| Applicable materials | Rubber & Plastic |

| Plate Pressure | 10/20/30/50/100T or customized |

| Plate area | 300 × 300 mm or customized |

| Temperature scope | Ambient temperature ~ 300°C |

| Temperature control accuracy | ±2°C |

| Heating method | Electric heating |

| Cooling method | Water cooling |

| Control mode | Microcomputer + physical keys / PLC + touch screen |

| Oil cyclinder stroke | 180 mm |

| Net weight | Approx. 700 kg |

| Power supply | 3∮,AC 380 |

Rubber Plate Vulcanizing Press Features

- Small size, complete functions, stable temperature and low noise

- Use imported digital model KDB high carbon steel solid pressure plate

- Platen size can be customized as required

- With two laminated plates, the upper layer is heated by electricity, and the lower layer is cooled by circulating water

- Equipped with an oil pressure system with an automatic pressure compensation function

- P.I.D temperature control

- There are button control models and PLC touchscreen models to choose from

- PLC can realize automatic mold opening and closing

- Equipped with security door

- Easy to operate, save material, accurate temperature, suitable for laboratory research and development

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.