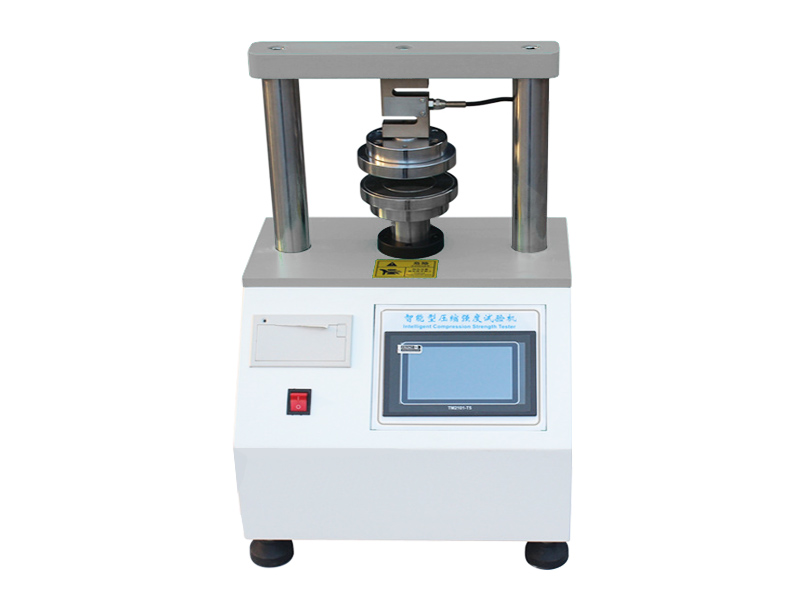

Crush Tester for Paper, Board and Corrugated Fibreboard

Compression Testing Machine is the most commonly used crush tester used to determine the compressive strength of paper, board and fibreboard.

It is a piece of multi-purpose paper and packaging testing equipment. Different test items can be conducted as long as this machine is configured with corresponding auxiliary equipment. This instrument has many other different names, such as Ring Crush Tester, Flat Crush Tester, Edge Crush Tester or Edgewise Crush Tester, Pin Adhesion Tester, Corrugating Medium Tester, Corrugated Crush Tester.

Test Items

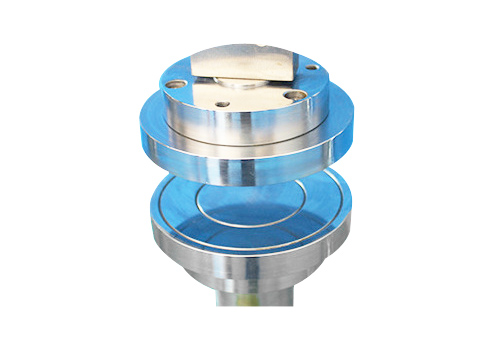

RCT: Ring Crush Test Sampling Device and Test Piece Holder need to be equipped.

ECT: Edge Crush Test Sampling Cutter & Guide Blocks need to be equipped.

FCT: Flat Crush Test Sampling Device needs to be equipped.

PAT: Pin Adhesion Test Fixture needs to be equipped.

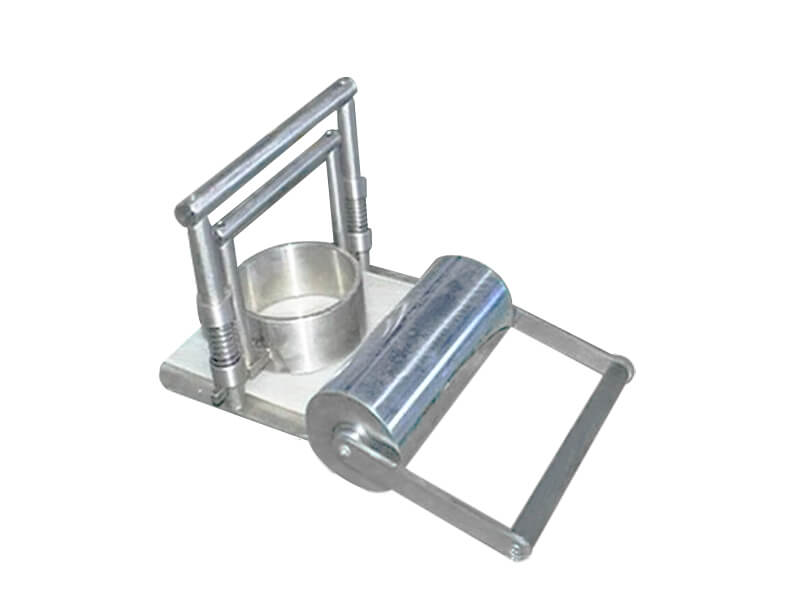

CMT: Corrugating Medium Fluter & Rack and Comb needs to be equipped.

CCT: Corrugating Medium Fluter & Edge Crush Specimen Holder need to be equipped.

Feel free to contact AMADE for consulting more details on sampling devices and auxiliary equipment.

INQUIRE

The core components of this equipment acting on the test piece are two platens: An upper and a lower platen. Each is large enough to accommodate the test piece completely and sufficiently rigid to withstand significant deformation by the compressive forces. The platens are mounted to have not more than 0.05 relative movement in the horizontal plane, and their surfaces are parallel and flat to each other.

The lower platen is movable towards the other at a constant speed. A precision load cell in the upper platen starts detecting and collecting the compressive force once the lower platen contacts the upper platen via the sample assembly. The real-time values are transmitted to the machine’s control center for analysis and presentation, along with the increasing force exerted on the specimen by the moving platen. The maximum force per unit length that a test piece can support until the onset of failure when a compressive force is applied can be measured.

Tests Standards

- For RCT — ISO 12192, DIN 53134, SCAN P34, TAPPI T 822, APPITA / AS 1301.407s

- For FCT — EN 23035, ISO 3035, SCAN P32, TAPPI T 825, FEFCO No. 6, PPITA / AS 1301.429s

- For ECT — ISO 3037, ISO 13821, DIN 53149, SCAN P33, TAPPI T 823, TAPPI T 838, TAPPI T 811, TAPPI T 839, FEFCO No. 8, APPITA / AS 1301.444s

- For PAT — TAPPI T 821, FEFCO No. 11, APPITA/AS 1301.430s, JIS-Z-0402, JIS-Z-1516

- For CMT — ISO 7263, DIN 53134, SCAN P27, TAPPI T809, APPITA / AS 1301.434s

- For CCT — TAPPI T 843, SCAN P42

Main Technical Specifications

| Model | AT-P8004 |

| Test Type | RCT, FCT, ECT, PAT, CMT, CCT |

| Load Unit | N, kgf, lbf |

| Strength Unit | N / m, N / cm, N / mm, Lbf / in, Kgf / cm, kN / m |

| Measurement Range | 5 ~ 2000 N, Resolution 0.1 N |

| Load Accuracy | Indication error ≤ 1% |

| Test Speed | 12.5 ± 2.5 mm / min or adjustable |

| Return Speed | 30 mm / min |

| Flatness | < 0.05 mm |

| Parallelism | < 1/2000 × B(B: dia. of Round compression platen ) |

| Motor | 1/4 HP |

| Max. Distance of Compression Platen | 80 mm |

| Compression Platen Diameter | 100 mm |

| Weight | About 50 kg |

| Dimension | About 420 ×350 × 640 mm |

| Power | 1 phase, AC220V, 2 A, 50/60Hz or Specified |

Compression Testing Equipment Features

- Equipped with a synchronous motor to provide stable and robust power.

- It adopts a high precision load sensor and precision ball screw transmission to ensure the tester runs more stable and test results are more accurate.

- This machine is capable of implementing different determinations such as ring crush test, corrugated board flat compression test, edgewise compression strength test, pin adhesion strength test, corrugating medium flat compression test and corrugated crush test.

- Fitted with a 7-inch touch screen, which can display the test value, maximum peak value, and current force value in real-time (Non-touch screen display is optional).

- Controlled by a microcomputer. Automatic storage and statistical analysis of test results are available, and test results include maximum peak value, displacement, maximum value, minimum value, average value, etc.

- Three units can be switchable at will: N, kgf, lbf.

- Configured with multiple protection functions: data memory function, travel protection, overload protection, automatic reset, fault alarm, etc.

- Fitted with a built-in thermal micro printer to print the results.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.