IPX5-6-6K Waterproof Test Device Supplier

Open-type IPX5/IPX6/IPX6K Waterproof Test Setup is able to deliver different levels of high-velocity water jets onto the sample under test from different angles at a distance of 2.5 ~ 3 meters, and after a specified time of exposure, the rigorous waterproof performance of the sample against the impact of high-speed water jets is determined.

The open-type test setup from AmadeTech has advantage of eliminating the constraints of sample mounting space over the box-type IPX5/6/6K test device, as it has got rid of the chamber that holds the sample. This feature allows it to accept different types of large or irregular-sized samples.

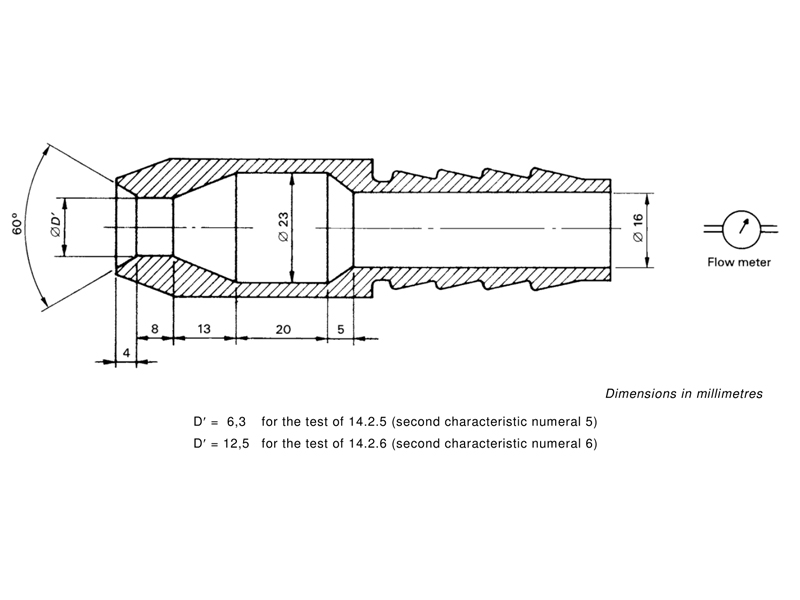

Depending on the test items, we equipped each device with two metal nozzles of different sizes: one nozzle has an opening with an inner diameter of 6.3 mm, which is used for IPX5 and IPX6K testing, and the other nozzle has an opening with an inner diameter of 12.5 mm for IPX6 testing. During the test, high-speed water jets are sprayed from a nozzle.

You can hold the nozzle and spray water onto the sample from any intended angle and direction when testing, facilitating the test to be performed flexibly and enabling the sample enclosure to be fully exposed to water jets, which is the second advantage of the open-type test device over the box-type test device.

Spray nozzle schematic diagram

Alternatively, a stainless steel stand with retaining device is provided to hang and fix the nozzles during the test. We provide a dedicated turntable which can rotate forward and reversely under control to allow you to place and secure the sample, and the sample power can switched on and off alternately after connected to the power socket on the turntable base if required.

As we know, the formation of strong high-velocity water requires strong water pressure beyond that of ordinary tap water. In order to obtain the required pressures, our open-type IPX5/6/6K waterproof test setup comes with a separate stainless steel box. This box contains a large-capacity water tank, high-pressure water pumps, electronic control system and operating system, etc. The water tank can hold up to appr. 550 L water as temporary water supply during testing, and a tap water pipe is required to be connected to the inlet of the water tank to add water in advance. The water in the water tank is pumped into the corresponding pipes driven by the high-pressure water pump, and then sprays out from the nozzle to form a strong water jets.

There is an operating panel on the front of the box that consists of a controller, a pressure gauge and flow meters. The commonly used configuration for the controller is PLC + a 7-inch touch screen, or you can choose a lower-cost controller with physical buttons and digital display screens. Through the controller you can select the desired test item, set the required parameters such as test time and sample power status, start and end the test. As the test level changes, you can manually adjust the water flow rate to the specified value.

AmadeTech has the ability to provide various customized configurations and solutions according to your requirements. For example, we can tailor a turntable with a larger size and greater load capacity for your sample, or provide a set of equipment equipped with multiple nozzles, or integrate different IP waterproof testing projects into one equipment to help you save costs and reduce equipment footprint in the laboratory. In short, if you have any requirements for IP waterproof testing, please contact us. Here at AmadeTech, there is always a solution that is right for you.

Conforming Test Standards

IEC60529, ISO 20653, IEC 60598-1, IEC 60068-2-18, IEC 60034-5, DIN 40050-9

Technical Parameters

Model | AT-1005C | AT-1005C-600 | AT-1005C-800 | AT-1005C-1000 | AT-1005C-1180 |

Equipment type | Open-type | Box-type with an enclosed chamber | |||

inside chamber dimensions | / | (W) 600 x (D) 600 x (H) 600 mm | (W) 800 x (D) 800 x (H) 800 mm | (W) 1000 x (D) 1000 x (H) 1000 mm | (W) 1180 x (D) 1180 x (H) 1180 mm |

Overall dimensions | (W) 1100 x (D) 900 x (H) 1300 mm | (W) 3550 x (D) 1050 x (H) 1600 mm | (W) 3550 x (D) 1050 x (H) 1600 mm | (W) 4050 x (D) 1250 x (H) 1850 mm | (W) 4350 x (D) 1400 x (H) 1900 mm |

Turntable diameter | Dia. 600 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm |

Turntable height | Fixed | ||||

Nozzle opening size | Dia. 6.3 mm (IPX5 & IPX6K), Dia. 12.5 mm (IPX6) | ||||

Water flow and pressure required | IPX5: 12.5 L/min ± 5%, pressure appr. 30 kPa IPX6: 100 L/min ± 5%, pressure appr. 100 kPa IPX6K: 75 L/min ± 5%, pressure appr. 1000 kPa | ||||

Water jetting distance | 2.5 ~ 3 meters | ||||

Control mode | PLC + 7-inch touch screen | ||||

Feature | Allows energized samples during the test | ||||

Features

- Made of 304 stainless steel.

- The removable nozzle allows the operator to hold it to spray samples flexibly.

- Equipped with a stainless steel stand to hold the nozzles.

- Comes with a rotatable turntable to mount the sample.

- A waterproof socket is reserved to power on the sample under test if required.

- Has a high definition touch screen to realize human-machine interaction.

- Able to complete the test automatically under control.

- Multiple water meters are available to achieve precision regulation and control of water flow.

- Water supply and testing control box is fitted with casters to facilitate movement.

- Supports various customized configurations and solutions.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.