Frame-type and Wall Mounted IPX1 / IPX2 Waterproof Drip Test Apparatus Supplier

IPX1/IPX2 Test Setup is a drip apparatus intended to determine the protection against vertical water drips. Different from the conventional rain test chambers featuring an enclosed space to accommodate the sample, the open-type IPX1 and IPX2 test setup from AmadeTech has no space limitations and can theoretically accept larger-sized and irregular-shaped samples.

The machine is equipped with a movable turntable with casters. When mounting the sample, you can easily place and fix the sample on the test turntable from multiple directions. You can even move the turntable out to mount the sample. After the sample is mounted, reposition the turntable so that the geometric center of the turntable aligns with that of the drip box. Thanks to the no enclosure design, when the machine is running, you can stand next to it and clearly observe the real-time status of the sample exposed to rain from at least three directions, so as to better understand its waterproof performance and evaluate the test results. In addition, the simple structure facilitates the customization of more drip boxes of different sizes economically.

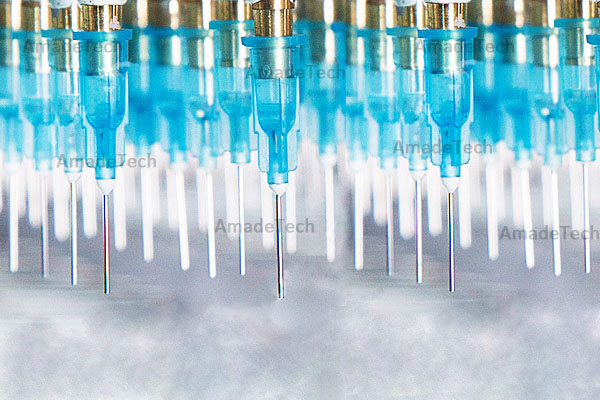

The drip box is a container with equal length and width. Inside it is a sealed water tank to temporarily store the water needed to simulate dripping rain. There is a water inlet on the top of the drip box connected to a water pipe. During the test, water from the water pipe is continuously injected into the drip box. The bottom of the drip box is covered with dense needles, and the number of needles varies according to the size of the drip box. The needles of 0.4 mm in inner diameter are arranged in a grid pattern and are spaced 20 mm apart from each other.

Dripping needles

The joints of these needles are push-in mountable and are easy to replace when required. A mesh guard is added to the area in front of the needles to prevent the operator’s body from accidentally touching the needle and causing injury.

To extend the service time of the drip box and needles, AmadeTech specially installed an air blowing system for the drip box. When all the test items using this equipment for the day are completed, you need to press the blow button on the control box to pressurize the drip box to drain all the remaining water inside to prevent water from being stored in the box for a long time to form scale and dirt.

Each IPX1/IPX2 test setup is quipped with a separate control box. The water pipes, compressed air pipes, and wires required for the test all need to pass through this controller. The water inlet is equipped with a filter to improve the purity of the water and reduce the chance of clogging needles.

There is a touch screen on the front of the control panel. You can set necessary test parameters, control test status and monitor test data with it. The lifting and lowering operation of the drip box is also integrated into this touch screen. A manual water flow adjustment device located under the panel of the controller allows you to easily adjust to the specified water flow rate after actuating the machine.

Control box

AmadeTech open-type IPX1 & IPX2 Test setup is available in 2 types: Wall mounted and Frame-type. Both allow customization of different sizes of drip boxes. The wall-mounted model means that the equipment needs to be installed on the vertical wall of a waterproof laboratory, so that the drip box is bracketed and moves up and down by the rotation of a screw under control. We will leave screw holes for fixing on the device and provide corresponding screws. You only need to drill holes in the wall and install them. The frame-type model means that the equipment involves an upright aluminum alloy rectangular frame to support the drip box and accommodate the turntable under the drip box. The drip box is moved up and down by an electric hoist under control. Both the frame and the turntable are movable by means of the casters at the bottom.

Wall mounted IPX1/2 drip tester

Frame-type IPX1/2 drip tester

Wall-mounted drip test equipment

Frame-type drip test equipment

Photoelectric senser and limiting stopper

No matter what version of the device, both are equipped with upper and lower limiters and photoelectric sensing devices. The stopper is mainly to protect the drip box from colliding with the top of the sample or the turntable during manual lowering. The photoelectric sensing device is to ensure that the drip box and the sample always maintain 200 mm stipulated by relevant standards after completing automatic lowering: a light emitter and a light receiver are installed on the left and right sides below the drip box. The light emitted by the emitter is aimed at the light receiver and the distance between this light and the needle above is exactly 200 mm. When the drip box automatically descends under control, once this light is blocked by the sample on the turntable, the light receiver cannot receive enough light, the system determines that an obstacle has been detected, and the drip box immediately stops descending, obtaining the 200 mm vertical spacing between the needle and the top of the sample enclosure.

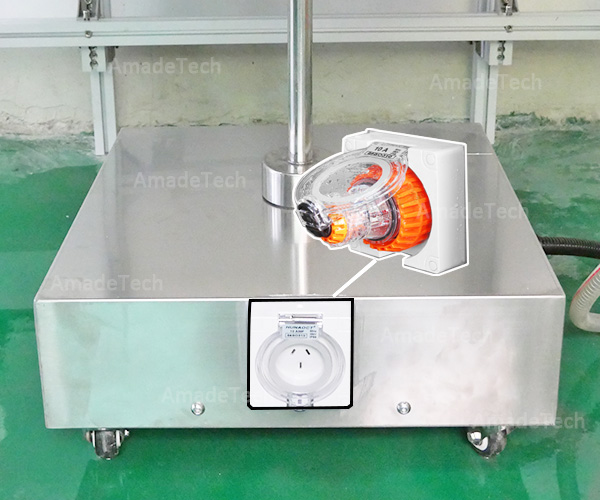

Socket for sample

In addition, AmadeTech IPX1/IPX2 test setup supports energized samples. We have a power socket at the bottom of the turntable to provide power for the samples. This power supply voltage can be integrated into the main power supply to keep consistent with the input voltage of the device, or it can be left with a separate interface in the controller to be customized by the user. The power cord of the sample needs to be connected to the waterproof plug we provided first, and then the waterproof plug is inserted into the power socket. The power supply can continuously supply power to the sample under control, or it can supply power intermittently, such as power supply for 30s, power off for 30s, and power supply for 30s again, and the cycle continues.

If you just want a single drip box or a single turntable rather than a complete set of equipment, that’s no problem at AmadeTech. We can provide flexible and personalized products to customers around the world. You just need to tell us your requirements and we can tailor them for you according to your sample size or weight requirements.

In addition, we can also provide box-type IPX1/2 test devices and other IP test equipment. Welcome to consult AmadeTech at any time.

Comparison between the Wall mounted, Frame-type and Box-type Drip Test devices

FeaturesVersions | Wall-mounted | Frame-type | Box-type |

Requirements for test site waterproofness | High | High | Low |

Water saving property | Low | Low | High |

Device mobility | Low | High | High |

Ease of mounting the sample | High | High | Medium |

Ease of viewing the sample | High | High | Low |

Integration with other IPX tests | Unavailble | Unavailable | Available |

Device cost | Low | Medium | High |

Conforming Test Standards

- IEC60529

- ISO 20653

- IEC 60598-1

- IEC 60068-2-18

- IEC 60034-5

- DIN 40050-9

Technical Parameters

Model | AT-C1005A2-400 | AT-C1005A2-600 | AT-C1005A-600 | AT-C1005A-800 | AT-C1005A-1000 | AT-C1005A-1200 | AT-C1005A1-600 | AT-C1005A1-800 | AT-C1005A1-1000 | AT-C1005A1-1200 | AT-C1005A1-1600 |

Equipment type | Box-type with an enclosed chamber | Wall-mounted | Frame-type | ||||||||

Drip area | (W) 400 X (D) 400 mm | (W) 600 X (D) 600 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 1600 X (D) 1600 mm |

Turntable diameter | Dia. 300 mm | Dia. 400 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 1000 mm | Dia. 1000 mm |

Overall dimensions | (W) 1050 x (D) 850 x (H) 1550 mm | (W) 1250 x (D) 1050 x (H) 1750 mm | (W) 850 x (D) 950 x (H) 2450 mm | (W) 1050 x (D) 1150 x (H) 2450 mm | (W) 1250 x (D) 1350 x (H) 2450 mm | (W) 1450 x (D) 1550 x (H) 2450 mm | (W) 1150 x (D) 850 x (H) 2450 mm | (W) 1350 x (D) 1050 x (H) 2450 mm | (W) 1500 x (D) 1200 x (H) 2450 mm | (W) 1700 x (D) 1400 x (H) 2450 mm | (W) 1800 x (D) 1800 x (H) 2700 mm |

Spacing of drip holes | 20 x 20 mm | ||||||||||

Drip pinhole | Dia. 0.4 mm | ||||||||||

Drip pan height | Fixed | 800 ~ 1800 mm adjustable | |||||||||

Turntable height | Adjustable | 600 mm (fixed) | |||||||||

Turntable angle | 0° (horizontal) or 15° inclined adjustable | ||||||||||

Turntable loading capacity | Max. 50 kg | ||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | ||||||||||

Control mode | PLC + 7-inch touch screen | ||||||||||

Feature | Allows energized samples during the test | ||||||||||

Open-type IPX1 & IPX2 Test Setup Features

- Made of 304 stainless steel and aluminum alloy.

- Drip box size can be customizable.

- The turntable size is customizable.

- The turntable is revolvable under control.

- The turntable supports a tilt of 15°.

- The drip box can be raised or lowered automatically with one press.

- The needles are easy to replace.

- Equipped with a photoelectric sensing device to automatically achieve a vertical distance of 200 mm between the needle and the top of the sample housing.

- Fitted with a touch screen to facilitate control and operation.

- Equipped with a filter in water inlet to enhance the purity of the water.

- Equipped with a set of air blowing device to discharging remaining water inside the drip box.

- Manual water flow meters available to adjust the flow.

- Equipped with adjustable upper and lower limiters to protect the device.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.