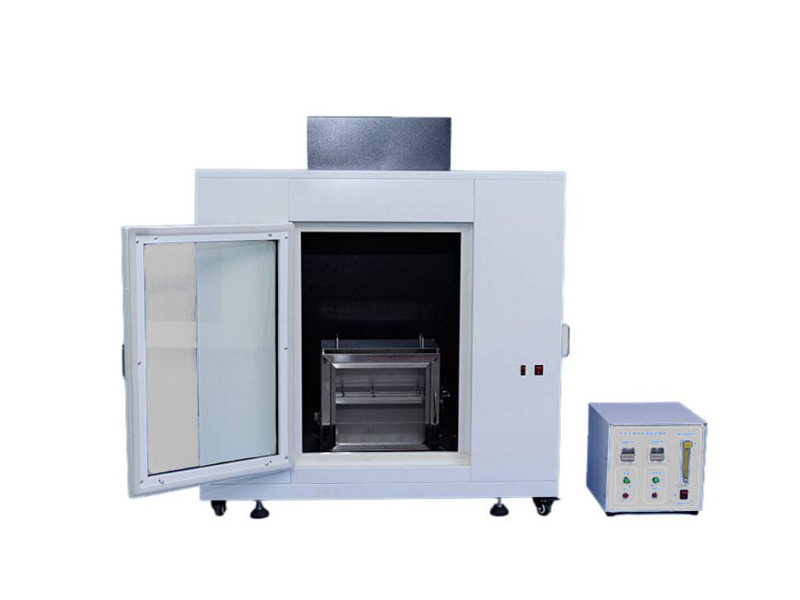

ASTM D2097 Upholstery Leather Flex Testing Machine

Newark flexing tester is used for determining the flexibility and adhesion of a finish on upholstery leather. The test is in accordance with the ASTM D2097.

This device consists basically of two pistons: One of which is fixed, and the other is capable of moving at 500 rpm with a stroke of 32 mm. The movable piston is also adjustable on its shaft to change the distance between the two pistons. This tester is configured with an LCD for data sets and monitoring the running state and a safety protection cover for safety consideration during the test.

Test Principle

The leather is mechanically flexed alternately from a flat position into a single or double bend. At the end of a preset number of bending cycles, the leather is visually examined for finish cracks.

Main Technical Parameters

| Model | AT-L9020 |

| Test Stations | 6 |

| Counter | LCD, 0 ~ 999,999 |

| Specimen Size | 76 × 114 mm |

| Flexing Stroke | 32 mm |

| Flexing Speed | 500 cpm |

| Safety Protection | Acrylic protective cover |

| Dimension | 92 × 55 × 45 mm |

| Weight | 75 kg |

| Power Supply | 1Phase AC 220V 50Hz 3A or specified |

Test Procedure

- Measure the thickness of the test piece to be tested.

- While in the closed position, adjust the pistons to 15 times the thickness of the test piece.

- Turn the pulley by hand until the pistons are the maximum distance apart. Clamp the test piece around the two pistons without stretching the test piece.

- Finish the first cycle by turning the pulley by hand and forcing the test piece into its flexing pattern.

- Turn on the power, and the test piece will follow this pattern during the whole flexing time.

- At the completion of the test, remove the test piece for evaluation.

- Use a 4× magnifying glass to examine the test piece for cracks in or through the finish.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.