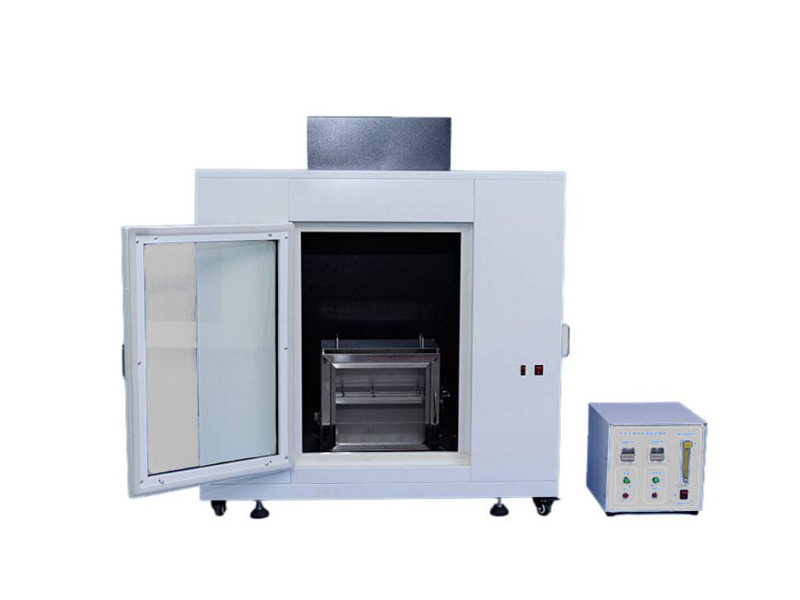

IULTCS Leather Rubbing Fastness Tester China Supplier

IULTCS & Veslic Rub Fastness tester is used to determine the color fastness of the leather to cycles of to-and-fro rubbing by reproducing the behavior of the surface of a dyed leather on rubbing with a wool felt.

This leather testing machine is applicable to all types of leather. Test leather and wool felt can be either dry or wet based on specific specifications.

Test Principle

One side of the leather specimen is rubbed against reference wool felt under a specified pressure for a specified number by forward and backward movements. The degree of color staining of the wool felt, or the change in color of the leather is evaluated with gray scales. Any other visible changes in the surface of the leather are also reported.

AmadeTech rub fastness test apparatus has a planar metal platform to allow a strip of sample leather to be placed on it lengthwise. Two metal square bars are located breadthwise at the front and rear ends of the platform, respectively, to fix the sample tightly with the help of four fastening screws through the bars. The gripping device at the outer end of the specimen, including the square bar, is a longitudinally movable assembly. It allows you to elongate the specimen linearly to a specified length in the rubbing direction by turning the long screw. This platform is able to move back and forth with a travel distance of 35 cm to 40 cm at a predetermined speed of (40 ± 2) cycles per minute under control.

There is a pivoted arm above the platform. A cylindrical metal block of 500 g in mass is at the free end of the arm. A 15 mm long, 15 mm wide, and 3.9 mm high cavity is located at the bottom of the metal block, which is used to hold the rubbing materials such as wool felt. The arm is required to be lowered to allow full and free contact between the rubbing material and the specimen. A piece of weight of mass 500 g attached to the top of the block is available to obtain a total downward pressure of 1000 g acting on the sample during testing. The cylindrical metal block is able to freely move vertically with the movement of the specimen.

Test Standards

- ISO 11640 Leather-Tests for colour fastness-colour fastness to cycles of to and fro rubbing

- SATRA PM 173 Colour fastness to rubbing-reciprocating method

- QB/T 2537 Leather-Tests for colour fastness-colour fastness to cycles of to and fro rubbing

- GB/T 20991 7.3 Determination of abrasion resistance of insole

- EN ISO20344 7.3 Determination of abrasion resistance of insole

- AS/NZS 2210.2 7.3 Determination of abrasion resistance of insole

- ISO 17700 Method A To and fro square rubbing finger fastness testing Footwear-test methods for upper components and insocks-colour fastness to rubbing

- DIN 4843 Safety footwear safety requirements testing

Main Technical Parameters

| Model | AT-L9007 |

| Finger Mass | 500 g |

| Weight Mass | 500 g |

| Rubbing Distance | 35 mm ~ 40 mm |

| Rubbing Speed | 40 ± 2 cycles / min |

| Sample Size | At least 100 mm × 20 mm or 120 mm × 20 mm |

| Horse Power | 120 W |

| Base of Finger | 15 mm × 15 mm |

| Fixtures Distance | 80 mm |

| Counter | Digital display, 0 ~ 999,999 cycles adjustable |

| Volume | 280 × 460 × 240 mm |

| Weight | 45 kg |

| Power | 1∮,AC 220 V, 3 A |

IULTCS Veslic Rub Fastness Tester Features

- It owns a compact size for the convenience of movement and placement.

- A graduated scale is available on the sample holding platform to faciliate extending the specimen manually in the direction of rubbing.

- Compatible with wet and dry tests.

- One or two test stations in one machine is available.

- A microcomputer controls the machine operation.

- Fitted with a digital display to set parameters and indicate running status.

- The machine is easy for users to use and maintain.

Leather Rub Fastness Test Procedure

- Mount a conditioned test piece into the machine and stretch it by 10% in the direction of rubbing.

- Place the weight so that the total mass of the finger can attain 1000g ± 35 g for ordinary leather.

- Mount a piece of conditioned wool felt to the finger.

- Place the finger on the leather and conduct the prescribed number of cycles.

- Repeat the test with the finger at a new position of the test piece if required.

- In case the pilling effect on the felt occurs, repeat the test.

- Remove the test piece and evaluate the color fastness of the specimen.

The above is just for reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.