IPX9K High Pressure and High Temperature Water Jetting Test Set-up

IPX9K High Pressure Water Spray Test Chamber is a waterproof testing device used to assess the protective performance of equipment subjected to high-pressure and temperature water jets. It can expose the sample to an environment generating water jets with a high temperature from any direction to complete the highest rating of waterproof test in the ingress protection (IP) test system. It is widely used in high-level waterproof tests on electronics, auto parts, battery packs, communication equipment, outdoor distribution boxes, etc.

AmadeTech’s IPX9K high pressure and temperature water spray test chamber provides an enclosed space whose dimensions can be tailored to your specimens. The interior contains a set of water spray devices and a turntable for placing the sample.

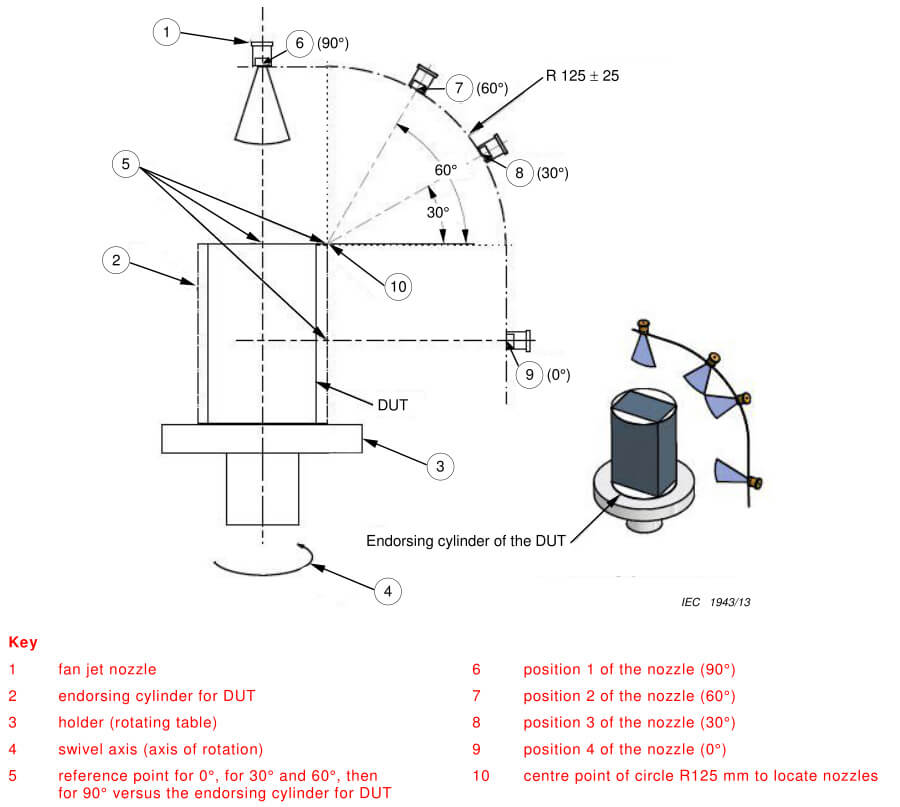

The water spray apparatus features four fan jet nozzles made of steel with a hardness of HRC62, arranged on the same vertical plane to achieve four spray positions of 0°, 30°, 60°, and 90°. Each nozzle position is allowed to be adjusted to achieve the required test distance with the DUT.

During the test, The heated water at (80±5)°C under the pressure of 8000 ~ 10000 kPa is sprayed from four nozzles in turn at a preset time interval.

Spray test assemble

The turntable, which can bear up to 50 kg, is able to rotate alternately clockwise and counterclockwise at a speed of (5±1) r/min throughout the test to ensure that the sample enclosure can be sprayed from different directions. There are holes distributed on the turntable to facilitate your fastening samples.

AmadeTech IPX9K water spray test chamber is characterized by an automatic water circulation device. The water flowing into the lower water tank from the test chamber is continuously pumped to the upper chamber of the equipment to achieve automatic recirculation, which not only saves water resources but also improves the constancy of the test.

IPX9K spray nozzle

We have configured the test equipment with a 7” touch screen, adding a programmable controller PLC to allow you to set and input parameters conveniently. The machine will automatically complete the test according to the set program. Real-time data is presented through the screen. When the test time is up, the machine automatically stops spraying water to enable you to inspect the specimen for any harmful effects.

AmadeTech can also provide open-type IPX9 high-pressure and high-temperature testing equipment (refer to the right picture). It does not have a closed test chamber and can accept test samples of unconventional sizes and shapes and meet personalized testing needs. If you have any questions and requirements, please feel free to contact us.

In addition, IPX1-6 Test Chambers capable of performing 6 different test levels of water ingression protection are also available from AmadeTech. If you are looking for more IP Testing Equipment, please go HERE.

If necessary, AmadeTech can also integrate other IP rating test equipment including any IPX1 – IPX2 – IPX3 – IPX4 – IPX5 – IPX6 into the IPX9 inner chamber to achieve multiple uses in one machine.

Test Standards

- IEC 60529

- ISO 20653

- DIN 40050-9, etc.

Technical Specifications

Model | AT-C1005FP-800 | AT-C1005FP-1000 | AT-C1005FO |

Equipment type | Box-type with a chamber | Box-type with a chamber | Open type |

Interior dimensions | (W) 800 x (D) 800 x (H) 800 mm | (W) 1000 x (D) 1000 x (H) 1000 mm | Turntable dia. 800 mm x height 700 mm |

Overall dimensions | (W) 1250 x (D) 1000 x (H) 1755 mm | (W) 1450 x (D) 1230 x (H) 1820 mm | Control cabinet (W) 1420 x (D) 1150 x (H) 1300 mm, Host (W) 700 x (D) 950 x (H) 2900 mm |

Spray angle | 0°, 30°, 60°, 90° | ||

Number of nozzles | 4 | ||

Distance between nozzles and the sample | 100 ~ 200 mm | ||

Water flow rate | 14 ~ 16 L/min | ||

Water temperature | Atmospheric temperature ~ 80 ± 5℃ | ||

Turntable rotation speed | 1 ~ 10 RPM adjustable | ||

Test time | 30 seconds for each angle | ||

Water pressure | 8000 ~ 10000 kPa | ||

Water impact force | 0.9 ~ 1.2 N | ||

IPX9K High Pressure and Temperature Test Chamber Features

- The body is made of 304 stainless steel for excellent rust and corrosion resistance.

- The door is equipped with a piece of tempered glass for better observing the sample under the test.

- Configured with a PLC module coupled with a 7” touch screen.

- Real-time parameters are displayed on the screen.

- Equipped with a set of rapid water heating systems.

- Supports high temperature and high-pressure water jetting.

- Four fan jet nozzles are easy to be replaced when required.

- The water spray distance is adjustable.

- The spray interval of different nozzles is adjustable.

- Turntable shape and load can be customizable.

- Multiple samples can be attached to the turntable easily.

- The turntable revolution speed is adjustable.

- Equipped with a water inlet to connect to a tap water pipe.

- Fitted with an automatic water circulation system to save water.

- Multiple protection devices are available against short-circuit, overload, water shortage, overflow, etc.

- Energized samples can be tested if required.

Frequently Asked Questions (FAQs)

Leave Your Message Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.