IPX1~IPX9 Comprehensive Waterproof Test Machine Manufacturer

This all-in-one IP combined waterproof test chamber is a versatile equipment covering functions of IPX1/2 drip test, IPX3/4/4K water spray test, IPX5/6/6K strong water jetting test and IPX9/K high temperature and high pressure water spray test. It is compatible with different levels of waterproof testing for medical products, consumer electronics, automotive parts and other products.

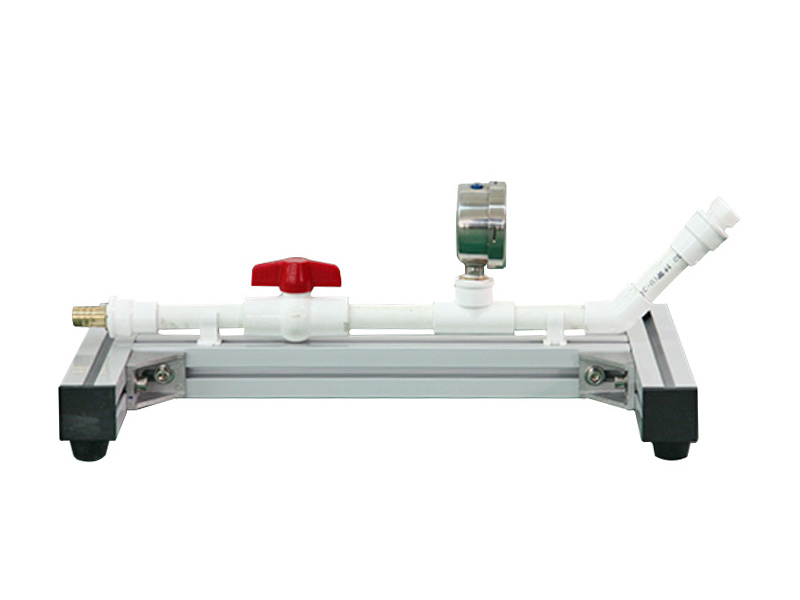

The machine is built up with welded rectangular heavy-duty steel tubing and the surface is covered with removable steel plates. The device features a test chamber in the upper part to hold the hardware devices for the different test items. A square drip box with needles distributed at a specified spacing is positioned at the ceiling of the inner chamber, and it is used to simulate light rain scenario enabling IPX1 and IPX2 testing. There is a stainless steel turntable supported by a vertical rod rooted from the bottom of the inner chamber is located in the middle of the chamber to hold the specimen under test, and the revolution speed and angle of inclination are adjustable as needed. A oscillating tube with nozzles is available in the middle area of the inner chamber to enable IPX3, IPX4 and IPX4K test at 120 degrees or 360 degrees of oscillation. The ends of the tube are positioned on the left and right walls of the inner chamber. A swing arm equipped with 4 high-pressure IPX9/K nozzles at the specified angle and spacing is mounted in the inside corner of the inner chamber. You only need to rotate the swing arm outward to align with the specimen attached to the turntable before performing IPX9/K testing. These nozzle specifications are strictly compliant with relevant standards and enable to spray high-temperature water of (80±5)°C at defined pressure at a specified intervals throughout the test. The innermost wall of the inner chamber has a rectangular or circular opening to which is attached a water guide conduit of not less than 2.5 metres in length, and the two jet nozzles for IPX5, IPX6 and IPX6K are positioned on the other side of the guide conduit. The nozzles can be fixed or swung up and down automatically. During the test, a jet of water is ejected from the nozzles through the guide conduit and onto the surface of the rotating specimen inside the inner chamber for a defined period of time.

The waterproof test chamber size is allowed to be customized as per your specimen dimensions. In addition, we provide personalized configurations allowing for various flexible combinations of test ratings from IPX1 to IPX9 integrated into the chamber in accordance with your test requirements. The sample under test can be powered on and off alternately if required.

IPX1~4 combined test chamber

IPX3~6 combined test chamber

IPX1~6 combined test chamber

IPX3~9 combined test chamber

AmadeTech IP integrated rain test chamber is equipped with a colorful touch screen and PLC. Test controls for all test items are integrated into this screen, greatly saving space and enhancing ease of operation. You can enter the interfaces of different test ratings to enter the necessary parameters by tapping corresponding icons, control the test status. The flow rate and pressure specified for each test item can be obtained by adjusting the electronic flow meter. Each waterproof test rating is independently controlled and does not interfere with each other. When the machine starts, it automatically completes the test according to the standard procedure and then stops automatically. All the data and progress of the testing process will be shown on the display screen in real time for you to view and monitor, ensuring the steady progress of the test.

Test Standards

IEC 60529

ISO 20653

DIN 40050-9

IEC 60598-1

IEC 60068-2-18

IEC 60034-5, etc.

Technical Parameters

Model | AT-C1005 series | |||

General parameters | Main material | #304 Stainless steel | ||

Controller | 7” touch screen + PLC | |||

Interior chamber dimensions | W1300 x D1300 x H1300 mm (Optional) | |||

Water supply | Tap water (Recyclable) | |||

Sample power supply | available | |||

Turntable rotation | Forward / reverse alternately | |||

Turntable speed | 1 ~ 5 rpm adjustable | |||

Turntable height | Adjustable | |||

Machine power | 3-phase, AC 380V, 50Hz or specified by user | |||

IPX1/2 parameters | Drip area | 1000 x 1000 mm (optional) | ||

Needle diameter | 0.4 mm | |||

Needle spacing | 20 mm | |||

Water flow rate | 1 ~ 5 rpm adjustable | |||

Turntable angle | 0° or 15° | |||

Test duration | 10 min adjustable | |||

IPX3/4/4K parameters | Oscillating tube diameter | 600 mm (optional) | ||

Inner diameter of oscillating tube | 15 mm | |||

Open hole aperture | 0.4mm (IPX3 & IPX4), 0.8mm (IPX4K) | |||

Open hole spacing | 50 mm | |||

Swing angle of oscillating tube | IPX3 ± 60°(120°) IPX4, IPX4K ± 180° (355° in actuality) | |||

Swing speed of oscillating tube | 1 second/60° 4 seconds for 2 x 120° 12 seconds for 2 x 360° | |||

Water flow rate | 0.1L/min per open hole (IPX3/IPX4) 0.6L/min per open hole (IPX4K) Electronically adjusted | |||

Test duration | 10 min adjustable | |||

IPX5/6/6K parameters | Nozzle diameters | Dia. 6.3mm (IPX5,IPX6K) Dia. 12.5mm (IPX6) | ||

Water jetting distance | Appr. 2.7 meters | |||

Nozzle swing mode | Fixed or automatically swing up and down under control | |||

Water flow rate | IPX5: 12.5 L/min±5% IPX6: 100L/min±5% IPX6K: 75 L/min±5% Electronically adjusted | |||

Test duration | Min. 3 min adjustable | |||

IPX9/9K parameters | Test water temperature | 80℃±5℃ | ||

Number of nozzles | 4 pcs | |||

Spray angle | 0°, 30°, 60°, 90° | |||

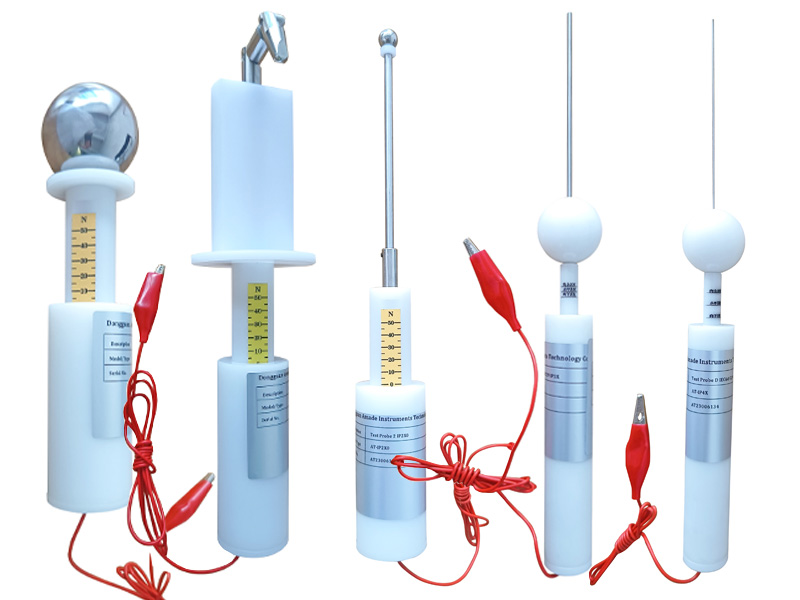

Water Impact force | 0.9 ~ 1.2N (Calibration device included) | |||

Distance between nozzles and sample | 100 ~ 150mm adjustable | |||

Water flow rate | 14 ~ 16L/min (Electronically adjusted) | |||

Test duration | 30 seconds per position, 120 seconds in total for one cycle, or set arbitrarily | |||

IP Water Test Chamber Features

- Constructed with heavy-duty steel tubes and 304 stainless steel plates.

- Multiple test functions from IPX1 to IPX6K and IPX9/K can be integrated into one test machine.

- Allows flexible selection in test items inside the chamber.

- The chamber size can be tailored to personalized need.

- Equipped with a 7” touch screen for parameter setting, test control and data presentation.

- The device terminates the work automatically once the predetermined test item is done.

- All test items are controlled independently to each other.

- Water flow and pressure are individually and electronically adjustable for each test item.

- The turntable rotation speed is adjustable.

- Built in a water tank to achieve water recycling throughout the test.

- No waterproof requirement on the test site.

- The sample can be energized over the test if needed.

- The needles and nozzles are easy to be replaced if required.

- Equipped with various protection devices such as water shortage, short circuit and overload.

- Easy to use and maintain for operators.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.