ISO 16750-4 / VW 80000 K-12 Ice Water Shock Test Equipment Supplier

Ice Water Splash & Submersion Shock Test Chamber is used to determine whether electrical and electronic equipment of vehicles that are easily splashed when driven on wet roads in winter can withstand damage and failures caused by different temperature expansion coefficients from thermal shock. When testing, the thermal shock is achieved by exposing the specimens alternately to simulated high temperature environment and low-temperature ice water. After specified number of cycles, the specimens are inspected for mechanical cracking, seal failures, loss of tightness and water ingress. This environmental chamber plays an essential role in the research and development, production and quality control of the automotive industry.

AmadeTech ice water shock test device mainly consists of 2 parts: The upper part is an inner chamber made of 316 stainless steel. It has the same function of a hot air oven and is able to obtain a uniform and stable high temperature environment by means of high-efficient heating devices and forced convection fan within a relatively short time, and the ambient environment inside it can be heated up to 150 degrees Celsius. The temperature parameter is collected in real time by a PT100 sensor. A front door is equipped for you to mount and remove samples. There is a piece of transparent viewing window and a lighting lamp in the door to facilitate you to see what’s happening inside the chamber throughout the test.

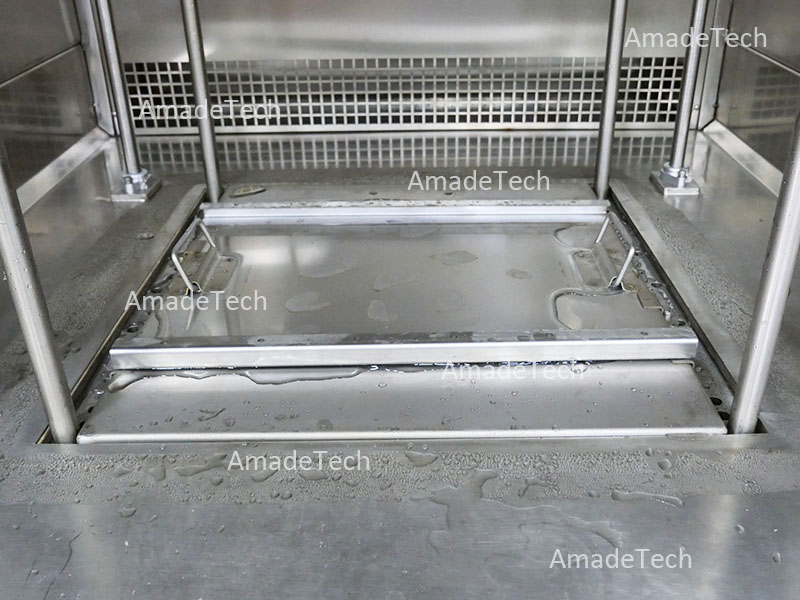

The lower part is a water tank made of the same materials as that of the inner chamber to resist all kinds of corrosion and adverse conditions during the test. Before the test, the water tank needs to be filled with a solution of the specified formula, and the water level has three options for you to choose: high, medium, and low. The high water level is used for ice water submersion test, and the low water level is used for ice water splash test to reduce the use of dust. Thanks to a powerful refrigeration system configured in the equipment, the solution in the water tank can be cooled to the minimum ±2℃ specified by the standard after the cooling command is given, and then the low temperature is maintained. The temperature control device adopts water circulation cooling to ensure that the water temperature is uniform and stable. The cleaning of the water tank is very important. Our equipment supports both automatic and manual cleaning modes.

There are four guide rods and a lifting device inside the inner chamber. Under the traction and control of the pneumatic chain, the square sample mounting platform can rise or fall to shuttle through the corresponding shaped opening at the bottom of the inner box. When the sample mounting platform rises to the highest point, it is just flush with the bottom of the inner box to facilitate your sample loading. You can directly fix the sample on the platform with suitable clamps, or you can add a hanging basket on the platform to hold the sample.

lifting device

specimen mounting platform

When doing the ice water immersion test, the sample mounting platform needs to be lowered to the lowest point, and the platform and the sample on it will be completely immersed in the liquid in the water tank. The rise and fall of the platform supports manual and automatic control. In the formal test, the automatic mode is used: the system will automatically complete the alternating rise and fall of the sample according to the specified exposure time and number of cycles according to your pre-set parameters, and finally complete the entire immersion test.

If you need to do an ice water splash shock test, there will be a fixed nozzle on the right side of the test chamber to spray ice water to the sample based on prescribed number of cycles. You can adjust the water spray distance to the specified 325±25 mm by moving the sample. The nozzle is made of 316L material, which can be disassembled and cleaned. The size and shape are strictly made in accordance with relevant standards. The flow rate of the ice water splash test is controlled by a flow sensor, that is, the signal of the flow sensor is fed back to the PLC, and the automatic constant flow is controlled by PID, and the flow rate is directly displayed on the touch screen.

ice water submersion shock test

Our Ice water shock test equipment is equipped with a PLC touch screen control system. All the interface layouts are simple and intuitive. Before the test, you only need to enter the necessary parameters such as inner chamber temperature, water temperature in the tank, splash time, submersion time, holding time, number of cycles, etc. After the test starts, the system will automatically heat up the inner chamber and cool down the water in the water tank. When the test conditions are met, the lifting device starts to work automatically to expose the sample to high and low temperatures alternately until the set cycle is completed. The entire test process, including the timing of the current working stage of the machine, the real-time temperature of the high-temperature chamber, and the real-time temperature of the water in the low-temperature water tank, will be displayed on the screen for you to monitor.

Please note that the ice water splash test function and the ice water submersion test function do not have to be integrated into one device at the same time. We can integrate one or both functions into the device according to your actual test needs, so as to help you save the overall procurement cost.

Test Standards

ISO 16750-4:2006,

GB/T 28046.4-2011,

VW 80000 K-12:2009-10, etc.

VW80000 K-13

Technical Parameters

Model | AT-1005GI series (Submersion test equipment) | |||

Overall dimensions | Appr. 1500 x 1900 x 2250 mm(W*D*H) | |||

Inner chamber dimensions | Appr. 1000 x 1000 x 1000 mm(W*D*H) | |||

Water tank dimensions | Appr. 600 x 600 x 600 mm (W*D*H) | |||

Water tank volume | Appr. 200 L (circulating water stirring) | |||

Sample mounting platform size | 500 mm (L) x 500 mm (W) x 500 mm (H) | |||

Sample weight | Not more than 50 kg | |||

Jet | Slit jet (1 pc) | |||

Distance between sample and jet | 325 ± 25 mm | |||

Inner chamber temperature range | RT+10℃ ~ +150℃ | |||

Heating rate | Less than 45 mins from RT+10℃ to 150℃ | |||

Min water temperature in tank | 0 ~ 4℃ | |||

Cooling rate | Less than 60 mins from 25℃ to 2℃ | |||

Submersion duration | 1 ~ 99 min settable | |||

Number of cycles | 1 ~ 99 times settable | |||

Test fluid | De-ionized water: 5% NaCI may be added | |||

Power supply | 3-phase, 380V, 50Hz, 12 kW (5-wire) | |||

Safety protection devices | Leakage protection, water shortage protection, short circuit protection, phase sequence protection, thermal overload protection | |||

Features

- If necessary, it is compatible with ice water splash test method and submersion test method.

- The outer shell is processed by high-quality steel plate, and the surface is sprayed with baking paint, which is beautiful and durable.

- The inner chamber is made of SUS316 stainless steel plate to ensure that it will not rust after long-term use.

- High-density glass fiber wool is used to ensure thermal insulation performance and maintain a balanced and stable temperature in the chamber.

- There is a transparent observation window on the door and an LED lighting lamp is installed to facilitate observation of internal test conditions.

- The high-temperature system uses a long-axis fan motor and a 316 stainless steel multi-wing impeller to achieve a strong convection vertical diffusion cycle, so that the temperature of the inner box is uniform and stable.

- A hole with a diameter of 100mm is left on the left side of the device to allow external test power cord or signal line.

- The control system uses a 7-inch touch screen + Panasonic PLC to ensure that the equipment automatically completes the test according to the set program.

- The compressor of the refrigeration system of the equipment adopts the French imported Taikang brand to ensure the refrigeration effect and reliability.

- R404R environmentally friendly refrigerant is used, and the entire system pipeline has passed the pressurized 48hleak test to confirm that the refrigeration system can operate stably for a long time.

- The ice water splash test uses flow sensors and PID to accurately control the flow.

- Separate circulation pumps are used for the ice water splash test and the submersion test.

- The water tank has the functions of automatic cleaning and manual cleaning.

- The equipment is equipped with safety functions such as leakage protection, water shortage protection, short circuit protection, phase sequence protection, and thermal overload protection.

- Fixable PU casters are installed at the bottom of the machine, which can easily move the machine to the designated location and fix it.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.