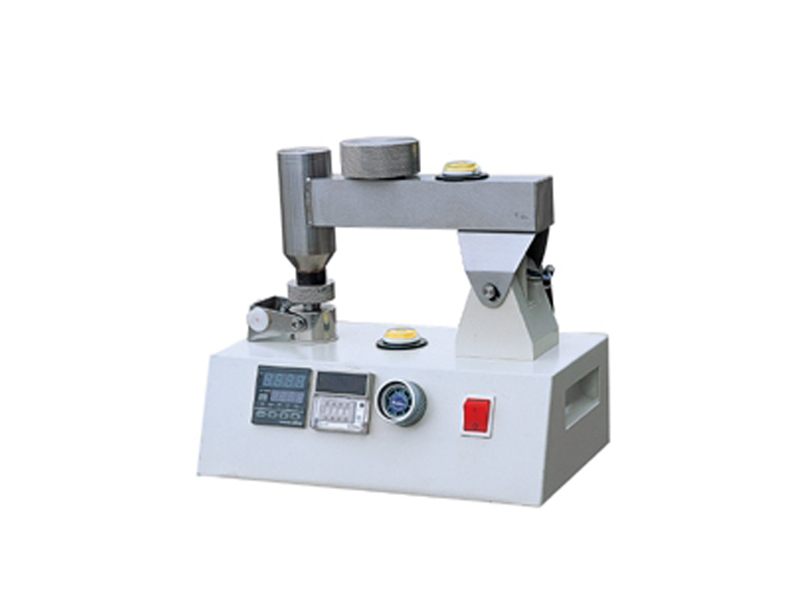

Heel Fatigue Testing Machine China Manufacturer

Heel Fatigue Tester is a shoe testing machine used to determine the performance of heels of ladies’ shoes to resist the repeatedly small impacts by simulating the blow of each step in walking.

Although this heel fatigue testing machine is primarily intended for plastic heels, it is also applicable to steel heel dowels and all types of high heels with any construction.

Test Principle

A striker head fixed rigidly to the pendulum strikes the test specimen assembly continuously at the speed of 1 blow per second, generating energy of 0.68 J each hit, until the failure of the heel takes place or expected fatigue resistance is observed.

Test Standards

BS-5131 4.9, ISO 19956, QB/T 2864, etc.

Main Technical Parameters

| Model | AT-F3015 |

| Impact Energy | 0.68 J ± 0.02 J |

| Impact Frequency | 60 blows / min |

| Impact Angle | 90° |

| Pendulum Bob | Dia. 57 ± 1 mm, Thickness 20 ± 1 mm |

| Impact Shaft | Dia. 12.5 ± 1 mm |

| Distance From the Bob Centre to the Hub Centre | 152 ± 2 mm |

| Striker Head | 35 mm (L) × 20 mm (W) × 6 mm (T) |

| Striker head corner radius | 3 mm ± 0.5 mm |

| Pendulum Moment | 0.68N.m ± 0.02N.m |

| Counter | LCD display 0~999,999 |

| Power | 1 phase AC 200V~240V, 3A |

| Dimension | 60 × 40 × 65 cm |

| Weight | 80 kg |

Heel Fatigue Tester Features

- This Footwear Heel Fatigue Resistance Tester is manufactured from excellent materials to ensure stability and durability.

- The height and angle of the tested heel can be adjustable.

- The number of the impact can be preset, and the machine carries out the test until the heel breaks or reaches the specified number of the impact.

- Fitted with an LCD and intelligent digital controller, simple to operate and use friendly.

- Configured with a precision pendulum to exert accurate energy on the specimen.

- If necessary, we can also produce non-standard instruments on the basis of specific requirements.

Heel Fatigue Test Procedure

- Check and ensure heel fatigue apparatus and prepared specimens are in position.

- Plug in power (a portable transformer is necessary If the venue voltage is 110V, as the built-in voltage is 220V).

- Insert the specimen assembly in the corresponding clamp of the machine, set and adjust the position of the specimen assemble at a suitable angle following the specified rule.

- Set the striking number or time on the controller, then start the machine.

- Check whether any damage has occurred at intervals of 60 min. If yes, record the number of the strike and describe the damage.

- If a complete failure does not occur after 20,000 blows, discontinue the test and have a record. Damage involving fracture or cracking of the heel at the point of the striker’s impact is regarded as invalid in the test.

The above is just for a reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.