Electrodynamic Vibration Test Equipment | Electromagnetic Shaker China Manufacturer

Electrodynamic Vibration Test System is used to simulate vibration states under various conditions by means of electromagnetic excitation to determine the vibration resistance, stability, and reliability of various components and finished products in service life.

Our electrodynamic shakers can accept a wide range of payloads to reproduce Sinusoidal, Random, Resonant search and dwell, Classical shock, Road simulation, and other vibration modes in single-axis or X, Y, Z multi-axis directions. The electrodynamic vibration test systems conform to ISO, IEC, ASTM, DIN, UL, MIL, and other international standards, widely used in aerospace, precision instruments, energy, communications, electronics, and other industries.

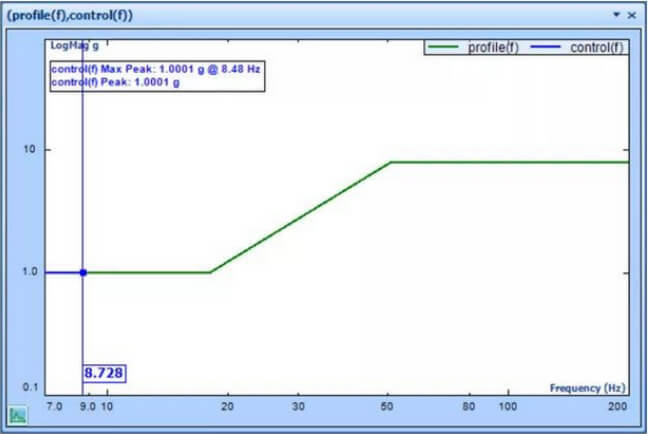

We take the vibration test of lithium-ion batteries in the UN 38.3 chapter of the dangerous goods transport safety manual formulated by the United Nations as an example. A set of the electrodynamic vibration test system with a small vibration shaker is a must-have device to complete this test. The standard requires the vibration on the cells or batteries to be a sinusoidal waveform with a logarithmic sweep of 7 Hz and 200 Hz and back to 7 Hz traversed in 15 minutes. You need to mark 3 mutually perpendicular mounting positions on the sample first (note that one of the vibration directions must be vertical to the terminal face) and then mount one of them on the electrodynamic shaker table with the help of the auxiliary devices. Start the machine after setting the logarithmic frequency sweep parameters on the computer. The machine will repeat the logarithmic frequency sweep 12 times in 3 hours and then end automatically. You are required to test the remaining two vertical positions of the sample in the same way. It will take a total of at least 9 hours to test one sample.

According to the weight of different sample cells or batteries (with 12 kg as the dividing line), the parameter settings for one-way logarithmic frequency sweep in the standard are different. In the first segment, both stipulate that the sample should be tested at an initial frequency of 7 Hz and a peak acceleration of 1 g until it reaches 18 Hz. You need to allow the machine to increase the peak acceleration from the second segment. For samples with a mass less than or equal to 12 kg, the peak acceleration is required to reach 8 g when the vibration frequency is about 50 Hz (The amplitude is maintained at 0.8 mm), and keep the acceleration until 200 Hz arrives. For samples with mass greater than 12 KG, the peak acceleration is required to reach 2 g when the vibration frequency is about 25 Hz (The amplitude is maintained at 0.8 mm), and maintain the acceleration until 200 Hz reaches.

UN38.3 vibration test spectrum

If you are interested in other lithium-ion battery safety testing equipment, please click HERE to learn more from AMADE TECH.

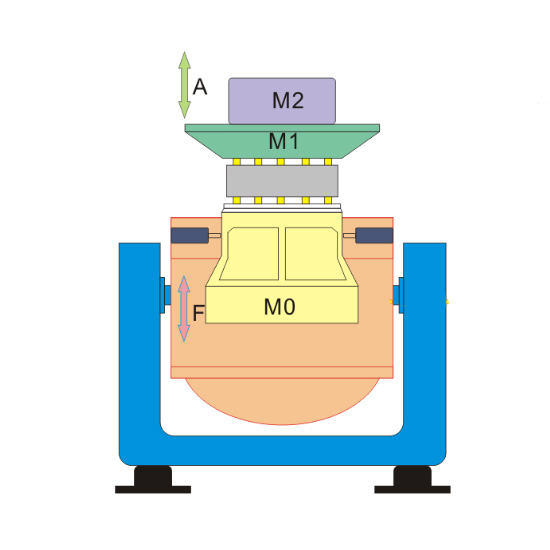

Electrodynamic Shaker Working Principle

The working principle of an electrodynamic vibration shaker is similar to that of a loudspeaker. That is, A current-carrying conductor moves under the action of electromagnetic force in a constant magnetic field. The armature of the electromagnetic shaker is located in a space with a high magnetic induction intensity.

When the required vibration signal is generated from the signal generator or vibration controller of the vibration test system and transmitted to the drive coil of the armature after being amplified by the power amplifier, the excitation force of the armature is generated when the corresponding alternating current passes through the drive coil. The vibration shaker table will generate the required vibration waveform.

Model | AT-EV1005 | AT-EV101 | AT-EV202 | AT-EV203 | AT-EV204 | AT-EV206 | AT-EV210 | AT-EV320 | AT-EV350 | AT-EV470 | >>more |

Frequency range (Hz) | 5~6000 | 5~6000 | 5~4000 | 5~4000 | 5~4000 | 5~4000 | 5~3000 | 5~2500 | 5~2700 | 5~2500 | >>more |

Rated Sine force (kfg/kN) | 55/0.539 | 100/9.8 | 200/1.96 | 300/2.94 | 400/3.92 | 600/5.88 | 1100/10.78 | 2000/19.6 | 5000/49 | 7000/68.6 | >>more |

Rated shock force (kfg/kN) | 100/9.8 | 200/1.96 | 400/3.92 | 600/5.88 | 800/7.84 | 1200/11.76 | 2200/21.56 | 4000/39.2 | 10000/98 | 14000/137.2 | >>more |

Max. acceleration Sine/Ranom (g) | 30/30 | 65/60 | 80/60 | 100/60 | 100/60 | 100/60 | 100/60 | 85/60 | 90/60 | 100/60 | >>more |

Max. displacment peak-peak (mm) | 20 | 20 | 38 | 38 | 38 | 51 | 51 | 76 | 76 | 100 | >>more |

Max. velocity (m/s) | 1.6 | 1.8 | 2.0 | 2 | 2 | 2 | 2 | 2 | 2 | 1.8 | >>more |

Payload (kg) | 20 | 100 | 100 | 120 | 120 | 300 | 300 | 300 | 500 (Up to 2000) | 500 (Up to 2000) | >>more |

Armature mass (kg) | 1.7 | 1.5 | 2.5 | 3 | 4 | 6 | 11 | 24 | 55 | 70 | >>more |

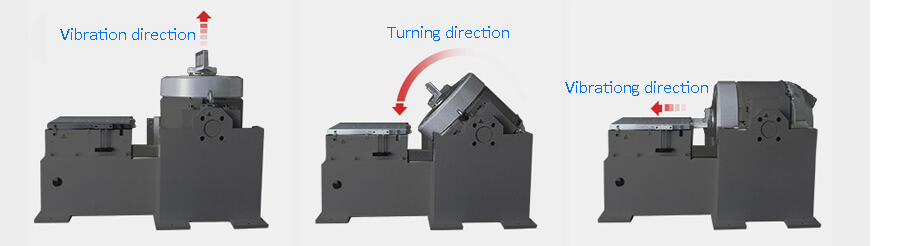

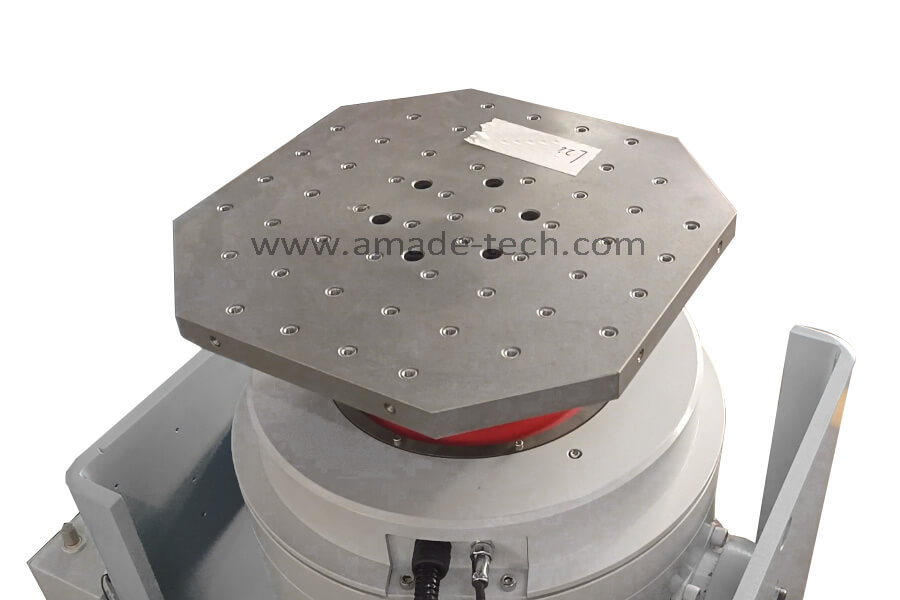

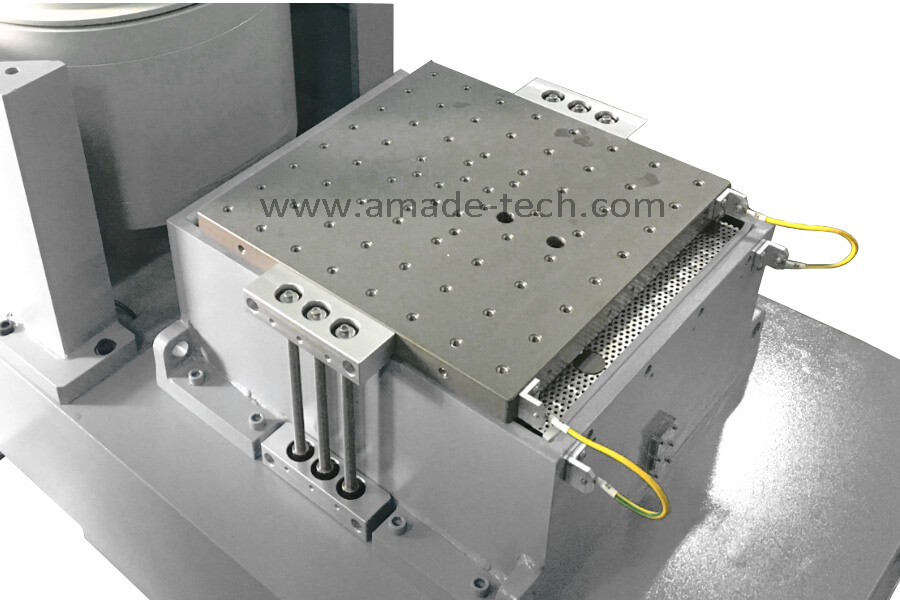

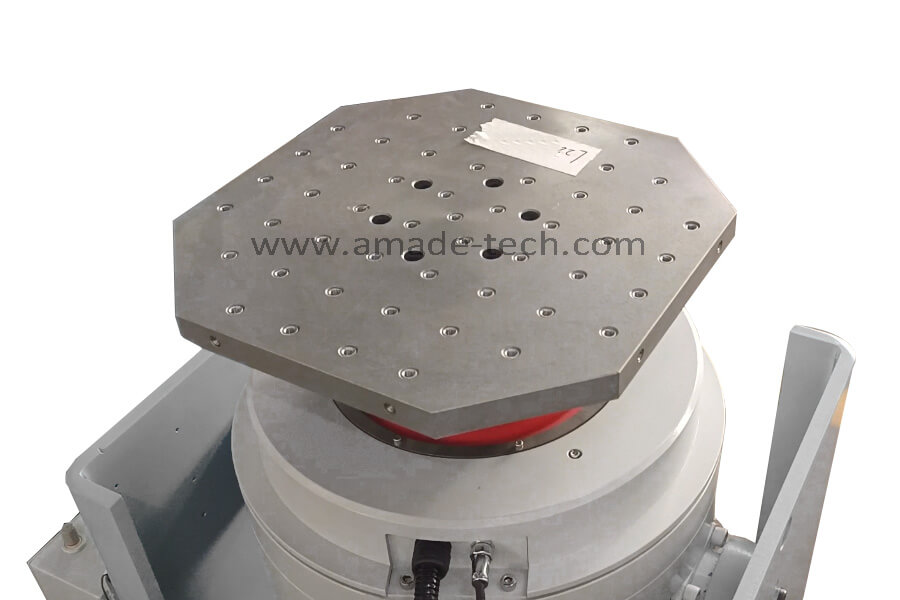

Considering the Electrodynamic Vibration System has a fairly wide range of uses accepting specimens of different sizes and shapes, AMADE TECH is able to provide different models and configurations of vibration shakers with low, medium, and high excitation forces to meet a wide variety of usage scenarios allowing the vertical vibration and horizontal vibration.

Different models vary in excitation force, frequency range, displacement, velocity, armature weight, dimension, machine layout, etc. One vibration shaker is available to turn flexibly for supporting vibration table testing in both directions.

If required, the electrodynamic shaker is allowed to be integrated into the temperature and humidity test chamber to provide specimens with artificial environments under the vibration test so as to access the environmental adaptation of vibrating specimens accurately.

If you have any questions, please feel free to reach us for solutions. Our sales engineers will propose the most suitable configuration and model according to your test requirements.

INQUIRE

Horizontal+vertical electrodynamic shaker system

Electrodynamic vibration system with an environmental chamber

Learn More About the Electrodynamic Shaker and Vibration Test System

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.