Auxiliary Equipment of Corrugated Fibreboard Edge Crush Tester Manufacturer

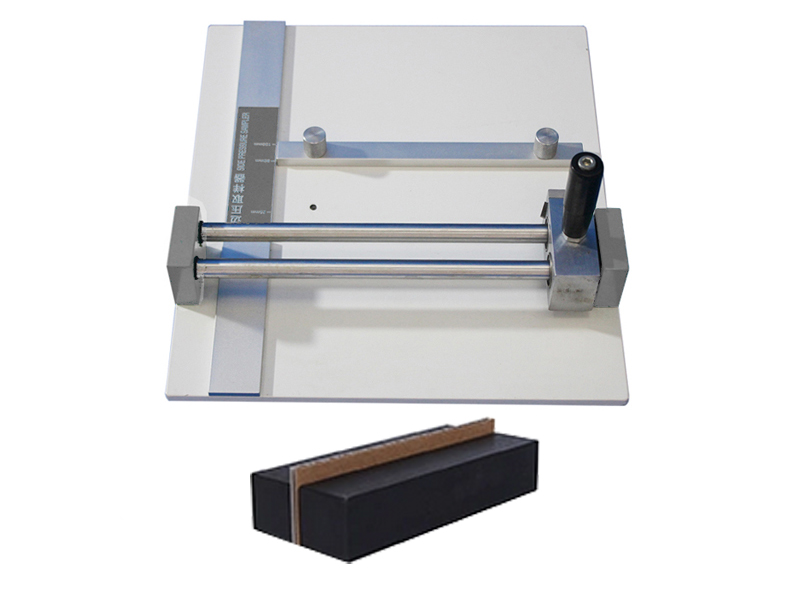

Edge Crush Test Sampling Cutter is an indispensable special sampling device for the corrugated fibreboard’s edge crush test and pin adhesion test. It can cut the standard test size accurately at a fast speed, which is an ideal auxiliary tool for corrugated cardboard and carton production, scientific research and quality inspection.

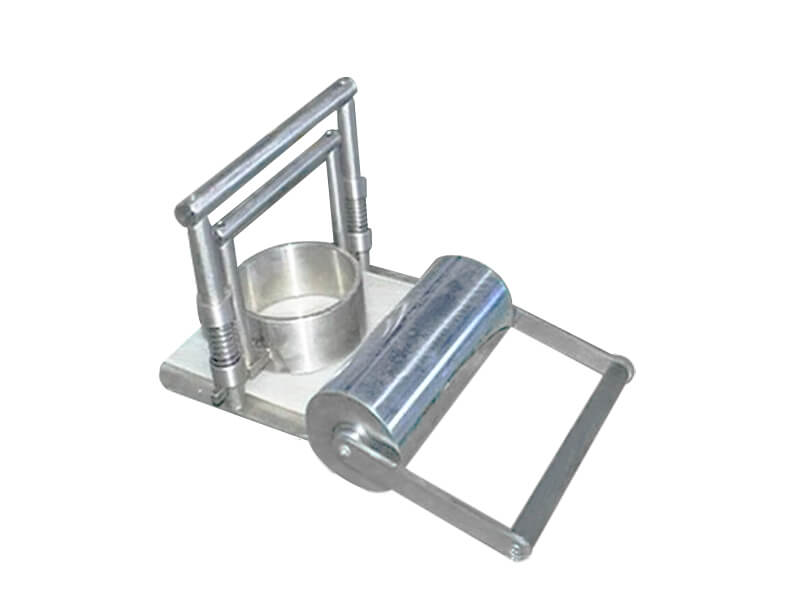

Gude Blocks (AT-P8004-D) are the sample holding devices when conducting the ECT on the corrugated fibreboard, consisting of 2 rectangular, smooth-finished blocks of approximately 20 mm × 20 mm × 100 mm. It is used to support the test piece and keep it perpendicular to the platen surfaces.

Edge Crush Test (ECT) is for measuring the edge crush resistance of corrugated fibreboard using a compression tester under the given conditions to predict the top-to-bottom compression strength of the final transport package formed from the corrugated fibreboard.

Test Standards

ISO 3037, DIN 53149, SCAN P33, TAPPI T823, TAPPI T838, TAPPI T811, TAPPI T839, TAPPI T845 TAPPI T472, TAPPI T808 TAPPI T818 FEFCO No. 8, TAPPI / AS 1301.44.

Main Technical Parameters of the ECT Sample Cutting Device

| Model | AT-P8004-C |

| Sampling Size | 25 mm × 100 mm for ECT |

| 25 mm × 80 mm for PAT | |

| Sampling Size Error | ± 0.5 mm |

| Max. Sampling Length | 220 mm |

| Max. Sampling Thickness | 18 mm |

| Adjustable Spacings | 25 mm, 30 mm, 80 mm, 100 mm, 120 mm |

| Cutting Depth | < 8 mm |

| Weight | 36 kg |

| Dimension | 430 mm × 380 mm × 200 mm |

Features of the ECT Cutter

- Made of high-quality stainless steel, with anti-rust and anti-corrosion.

- It is able to cut samples with precise parallelism, and different parallel spacings are adjustable.

- Equipped with two parallel precision guide rods, coupled with the use of high-quality sliding rails, and closely matched with imported Japanese blades, ensuring that it is easy to cut multilayer cardboard samples.

- The scale adopts laser engraving to enable the scale to be clear, durable and easy to clean.

- Configured with strong magnets, the blade can be installed more conveniently.

Instructions for the Use of the Cutting Instrument

- The cutting direction must be parallel or perpendicular to the flute direction, and the sample must not be loose during the cutting process.

- After each cut, the operator pulls the handle back to the position to be cut.

- It is strictly forbidden to put your hands in the cutting position to prevent injuries.

- If the cut of the cut sample is severely curled or skewed, the blade should be replaced (replacement method: loosen the screw on the knife holder assembly, remove the old blade, replace with a new blade, adjust the position and angle of the blade, and tighten the screw).

- When not in use for a long time, the blade, guide rods, etc., should be coated with anti-rust oil and covered for dustproof purposes.

- A small amount of lubricating oil should be added to the rail components and guide rods frequently.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.