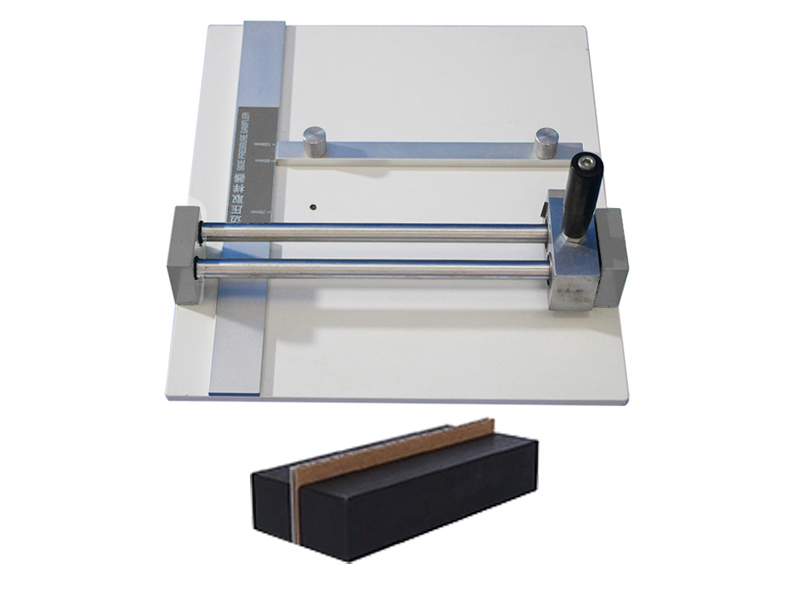

Corrugated Box Compression Tester China Manufacturer

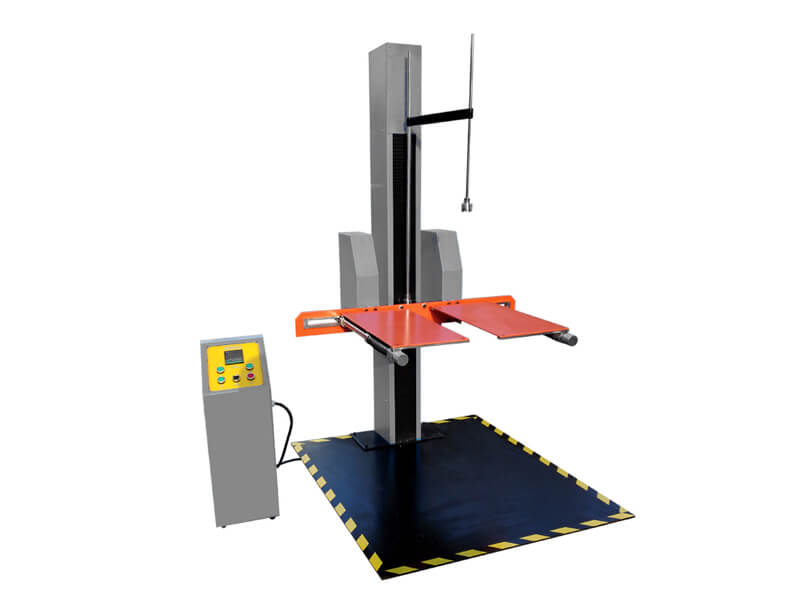

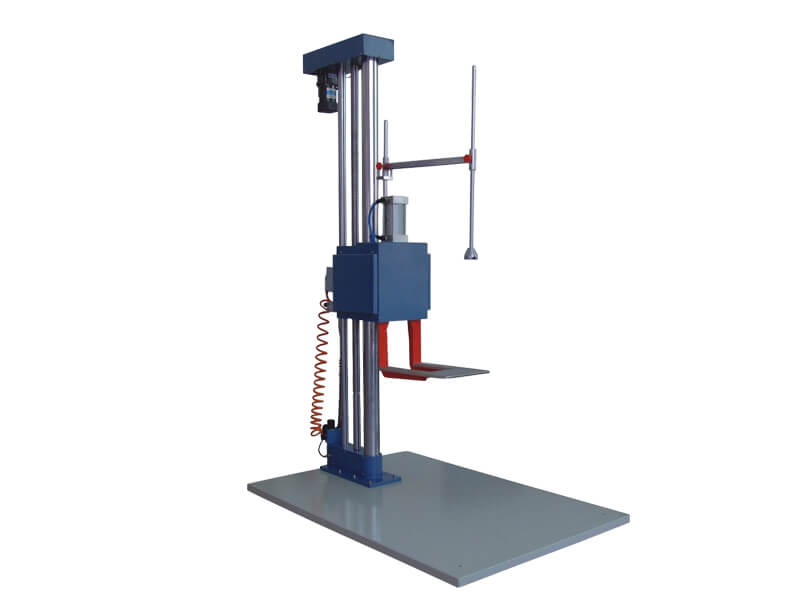

Carton Compression Tester is also known as the corrugated box compression testing machine, which is used to measure the ability of the transport packages with or without contents to resist external compressive strength applied to its faces, edges or corners. It is an extensively used method for corrugated box manufacturers to inspect product quality and judge whether or not their final products are up to design standards. It is a vital package testing machine.

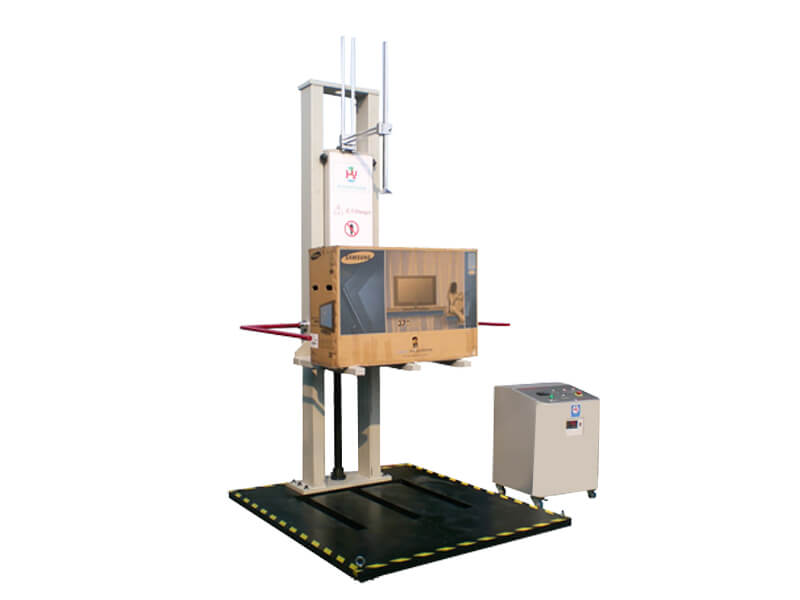

This carton compression tester can also be used to carry out the stacking test on complete and filled transport packages. When it comes to packaging material, there is no doubt that corrugated boxes as outer packs are the most frequently used packing way around the globe. It can’t be avoided that cartons filled with products are stacked upon each other during transportation and storage. Generally, people can’t judge by instinct how many cartons to be stacked in each column to result in displacement or damage to containers. This carton compression tester can be used to figure out the specific resistance value of each box to compressive strength in advance so that people can make appropriate arrangements in storage to prevent boxes from being crushed and damaged when stacking.

Test Principle

The test piece in a specified posture is placed between the platens of testing equipment. The upper platen moves downwards to the specimen at a constant rate. A precision load cell installed on the cross beam acquires and transmits the real-time load values to the control unit while the platen is in contact with the corrugated box’s surface / edge / corner. The compressive force is exerted on the specimen continuously at constant velocity until the critical value is reached. The essential parameters, like peak pressure, time, displacement, etc. can be revealed on the test report.

INQUIRE

Test Standards

- ISO 12048 Packaging – Complete, filled transport packages – compression and stacking tests using a compression tester

- ISO 2234 Packaging – Complete, filled transport packages and unit loads – stacking tests using a static load

- TAPPI T804 Compression test of fiberboard shipping containers

- ASTM D642 Determining compressive resistance of shipping containers, components, and unit loads

- ASTM D4169 Performance testing of shipping containers and systems

- JIS Z0212 Packaged freights and containers – Method of compression test

- GB/T 4857.4 Packaging – Complete, filled transport packages – compression and stacking tests using a compression tester

Main Technical Parameters

| Model | AT-P8004 |

| Capacity | 1000 kg (standard)

2000 kg (Optional) 3000 kg (Optional) 5000 kg (Optional) |

| Control & Display | Microcomputer – LCD (Standard)

Touch screen display (Optional) Computer + professional software (Optional) |

| Load Unit | Kgf, gf, N, KN, lbf |

| Stress Unit | Mpa, Kpa, Kgf / cm², lbf / in² |

| Displacement Unit | mm, cm, in |

| Force Resolution | 1/100,000 |

| Test Travel (mm) | 600, 800, 1000, 1200, 1500 (optional) |

| Plates Dimension (mm) | 600 × 600, 800 × 800, 1000 × 1000, 1200 × 1200, 1500 × 1500 (optional) |

| Drive Mode | AC frequency conversion motor + controller |

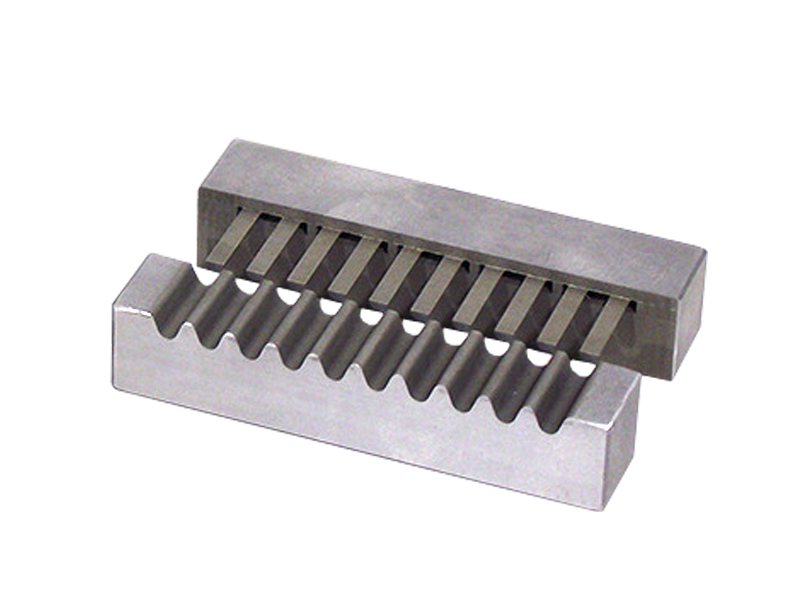

| Mechanical Parts | High precision ball screw |

| Test Speed | 5 mm ~ 100 mm / min adjustable

Commonly used are: 12.7 ± 2.5 mm / min 13 ± 2.5 mm / min 10 ± 3 mm / min |

| Data Storage | Up to 20 test results |

| Automatic Stop Mode | Reach predetermined load

Carton sample’s collapse Reach predetermined retention time Overload automatic stop Emergency stop Reach Upper and Lower limits |

| Safety Protection | Over-load protection

Over-travel protection |

| Power Supply | AC 220V 50/60Hz or specified |

Below Three Tests Can Be Performed by Amade Carton Compression Tester

- Compressive Strength Test:

A load is applied to the test piece. The sample is subjected to the escalating compressive force until the collapse happens, records the maximum load when specimen collapse occurs. - Constant Value Test:

Two parameters are to be set in the constant value test: Load force value and Deformation value. The user can set one or both of them according to the practical requirements. The measurement is completed when any one parameter of them or both reaches the set value. - Stacking Test:

The stacking test is used to check whether the sample can endure a constant pressure in a given period. Set up two parameters in advance: Compressive strength and testing time (hour). When the test starts, the system will check the current pressure at any moment. The measurement is finished when the test time is expired or the deformation value exceeds the set one within the testing period.

Carton Compression Tester Features

- High precision compression force sensor and uniform force distribution are available to ensure accurate test results.

- Configured with microcomputer control and LCD to enhance the operating convenience. (Touch screen control or Computer control optional).

- Over-load, Over-travel protections are available.

- Automatically releases compression force after completing the test, and it has an automatic stop function if reaching pre-determined compression force or collapse happens.

- Automatically records the applied load values (compression force) and deformation values.

- Holding the peak compressive force and retention time are available.

- A built-in compact thermal printer for test result printing directly is available.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.