Compact Open Mixing Mill Manufacturer

Bench-top Two Roll Mill is a compact polymer mixing machine with exposed rolls intended to plastify and mix polymer materials such as plastics, silica gel, elastomers, and other auxiliary elements. Additional agents are allowed to be added during the mixing to permit the occurrence of desired chemical reactions under the action of intensive shearing and squeezing. When the mixing is complete, the material mixture is removed from the rolls in a sheet form.

It is widely used for small-batch formula testing, contrast, and quality control in polymer material research and development laboratories.

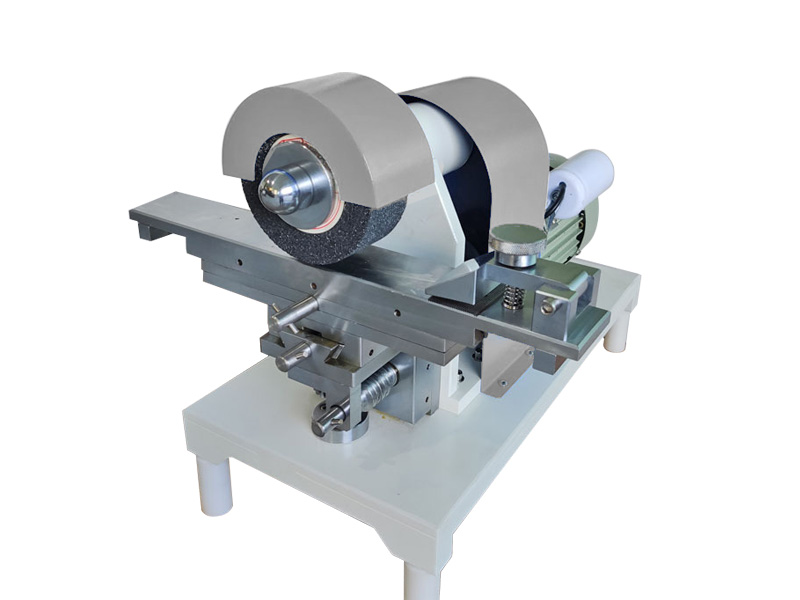

Compared to normal laboratory two roll mills, the compact one features a smaller diameter of the rolls, as low as 60 mm. But just as an old saying goes: “The sparrow may be small, but it has all the vital organs.” The same applies to AmadeTech’s bentch-top two roll mill.

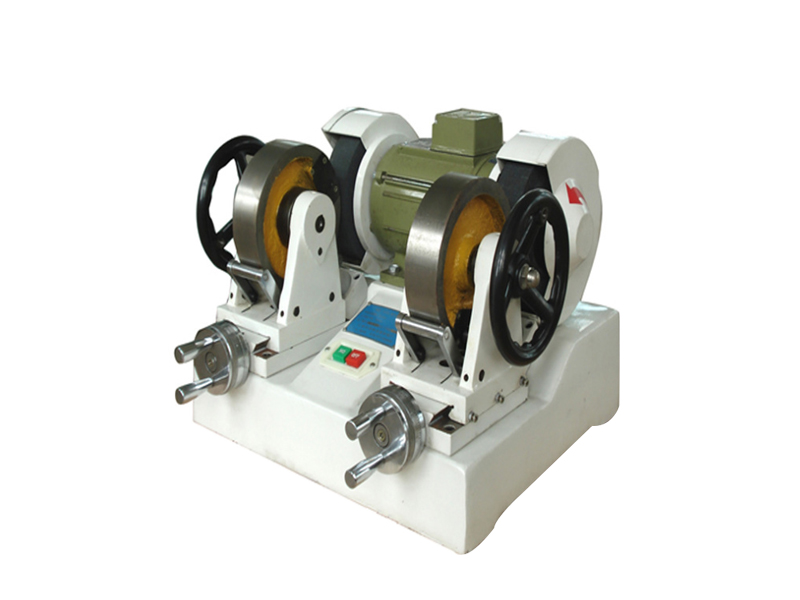

AmadeTech bench-top two roll mill is made up of rolls, drive units, control units, etc. Two cylindrical rolls side by side can rotate towards each other in opposite directions and can be adjusted for speed, temperature (optional), and nip according to testing tasks. We can provide flexible configurations for the rolls, including size, friction ratio, heating functions to suit personal requirements.

We equip the machine with a single motor to provide stable and accurate power delivery with the help of a special speed reduction mechanism. A control panel is designed on the top right of the face of the mill to facilitate operation. You can choose between the traditional physical button operation panel and the touch screen panel. Most importantly, the machine has two emergency stop buttons in the area most accessible to the operator’s hands. Once it is trigged, the roll will automatically stop and reverse for a certain angle to eliminate or reduce potential dangers.

Please note that this bench-top two roll mill is not suitable for masticating and mixing rubber materials with strong viscosity. If you are interested in AmadeTech’s regular laboratory two roll rubber mills or learn about related tips on usage, please click HERE.

Technical Parameters

Model | AT-R7024C-76 | AT-R7024C-100 |

Type | Desktop | |

Roll dimensions | 76 mm (Dia.) x 260 mm (L) | 100 mm (Dia.) x 300 mm (L) |

Roll hardness | 50 ~ 60 HRC | |

Roll surface treatment | Chromed-plated and mirror-polished | |

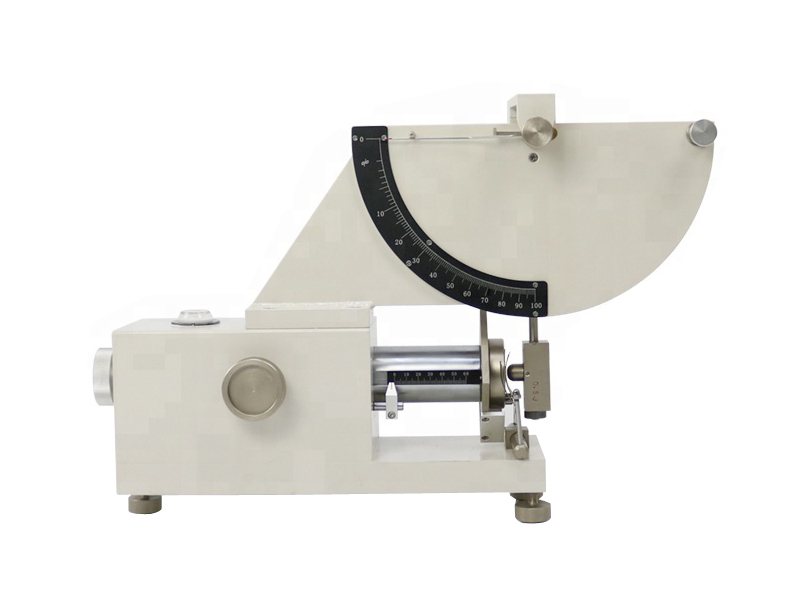

Roll nip | 0.1 ~ 3 mm, adjustable | 0.1 mm ~ 5 mm, adjustable |

Friction ratio | 1:1.27 | 1:1.25 |

Roll revolution speed | 0~28 rpm adjustable | 0~30 rpm adjustable |

Roll heating mode | Electrical heating | Electrical heating or no heating |

Roll temperature range | Ambient temperature ~ 250°C, adjustable | |

Temperature uniformity | 2°C | |

Safety features | One-button emergency stops | |

Motor power | 400 W | 750 W |

Power supply | 1-Ph, 220/110V, 1.2 kW | 1-Ph, 220/110V, 1.6 kW |

Dimensions | 600 x 350 x 380 mm | 680 x 350 x 450 mm |

Weight | Approx. 70 kg | Approx. 80 kg |

AmadeTech Benchtop Two Roll Mill Features

- Compact sizes enable it to be placed on the table of the laboratory for use.

- The roll is made of rugged steel with polished and chromed treatment on the surface.

- The roll gap is adjustable.

- Dial gauges are available to indicate the roll nip width.

- Rolls can be heated to the temperature as high as 260 degrees Celsius.

- The roll speed is adjustable.

- Built-in PT100 temperature measuring sensors.

- One button for emergency stop is available.

- More advanced configurations are available if required.

- Ease of use and maintenance.

Leave Your Message Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.