Water vapour permeability of leather means the ability that the water vapour comes into the air whose humidity is lower than leather from the air whose humidity is higher through the leather or fur. Because leather has water vapour permeability, it can help wearers in discharging the sweat smell and water vapor to make body feel comfortable. Water vapor permeability is also used to represent the hygiene performance of leather, which is one of important indices of leather.

Water vapor permeability is the amount of water vapor which is permeated in unit area and within unit time, expressed by mg/(10cm²*24h), whose size is decided by porosity of leather. All factors such as structure of raw hide, processing procedure, finish that affect the leather porosity are directly related to water vapour permeability of leather. In addition, It is also subject to the temperature and humidity of environment, the higher the relative temperature and relative humidity are, the higher the water vapour permeability is.

The common methods of testing the water vapour permeability include static method and dynamic method. Now what we introduce is dynamic method using a Water Vapour Permeability(MVP) Tester: test specimen is fastened to the opening of a jar containing a given quantity of solid desiccants, then fix the jar to a rotating device. The air in the jar is agitated by means of desiccants during rotation at specified velocity. The air outside the specimen is flowing under a certain temperature and humidity. Water vapor permeates passing through the specimen due to humidity difference, then be absorbed by the desiccants. The amount of water vapour passing through the specimen is determined through measurements of mass of the jar.

Water Vapour Permeability Tester

Instruments

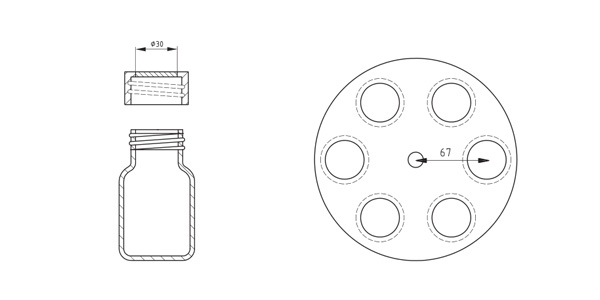

1.Several jars as below picture, comes with screw threads on the caps. There is a circular hole with 30mm in diameter on each of jars, which is same as the size of inner diameter of bottleneck. The plane of jar opening is perpendicular to inside walls of bottleneck.

2.Jars holder. Powered by electric motor, whose rotating speed is (75±5) r/min. Jar is placed on this disc with the axes of jars parallel to the axle of the disc and at a distance of 67mm.

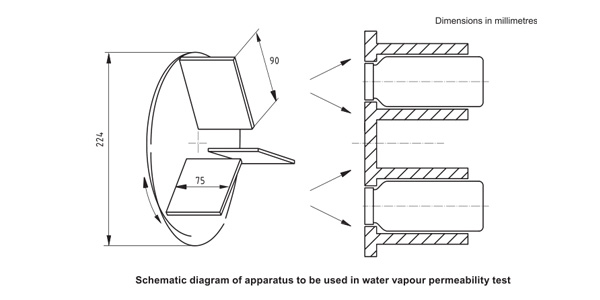

3.Fan. It is opposite to the mouths of bottleneck with 90mm*75mm in size of blade, whose distance from bottleneck shall be not less than 15mm when running, with rotating speed (1400±100) r/min.

4.Silica gel desiccant. Drying conditions: Dried in a drying oven in ventilated convection with (125±5)℃ by at least 16h for the first time, by 8h for the second time, then cooled in a sealed container for a least 6h. The size of silica gel particle shall be more than 2mm.

5.Precision balance(to the nearest 0.001g).

6.Stopwatch.

7.Vernier caliper which is capable of reading to an accuracy of 0.1mm.

8.Cutting die of 34mm in diameter.

Preparation of Test Specimens

1.Cut the test piece in accordance with specification to get the No. 10 specimen. Put the surface to be used up on the desk, to abrade slightly against the specimen using No. 180 abrasive paper by 10 times each from different directions, under a load applied of 200g. The surface to be used can’t be broken during abrasion.

2.Make above specimen into a circle, whose diameter is equivalent to external diameter of bottleneck.

3.Air condition the specimen in terms of specification.

Procedure

1.Fill the jar to the half with silica gel(59±0.5)g, fix the grain surface of specimen over the opening of jar, then fasten the jar to the prescribed holder, start the machine.

2.Use vernier calliper to measure the inner diameter of neck of second jar in 2 directions perpendicular to each other, to calculate the average diameter, expressed in millimeter, to an accuracy of 0.1mm.

3.If necessary, add a gasket between the bottle mouth and test piece or apply a thin layer of wax to the end of bottleneck, or take other measures for prevention of air leakage.

4.Switch off and take down the jar after 16 hours of rotation. Add the other half bottle of silica gel in the second jar, and take down the specimen from the first jar then fix over the neck of second jar as quickly as possible.

5.Weigh the second jar asap, noting down the time, and actuate the motor after the second jar is secured in the holder.

6.Power off and take down the jar for weigh again after 7 hours of revolution.

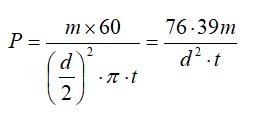

7.Calculation(based on below equation)

Where

P is the Water vapour permeability, expressed by mg/(10cm²*24h).

m is the mass of increment of the first and second weighing.

d is the diameter of jar neck.

t is the time of interval between the first and second weighing.

Explanation

1.Generally there is a layer of coating agent on the grain surface of leather, which lowers the water vapour permeability, but it will almost have on influence on the determination of WVP If being subjected to flexing or mild abrasion. If no otherwise stipulation, grain side shall be abraded slightly before test. The aim is to have a moderate scratch rather than get rid of coating. It is possible that deformation occurs in the process of abrasion because the force applied is not standard, so circular specimen can’t be cut before friction.

2.It is not necessary to seal the junction between specimen and bottleneck with wax for most of light leather test pieces, because specimen can be secured If screw is tightened downwards tightly. If the thickness of specimen is more than 3mm, wax is needed to be used for seal. Even for light leather, wax is required If water vapour permeability of test specimen is low or after embossing.

3.If the second jar needs to be waxed, the jar can be placed in an oven with 50℃ for heating before filling with silica gel and mounting specimen, then a layer of wax is smeared at the end of bottleneck. Apart from the leather with very high rigidity or unpermeability, there is no need to seal the junction of the first jar. The first time revolution of the first jar is intended to adjust specimen and air current balance of stable situation.

4.The water vapour permeability P in light of above formula is based on temperature 20℃ and 65% relative humidity difference between two side of specimen. If at constant temperature, the increasing proportion of WVP of most of leathers is roughly same as the ratio of relative humidity difference. Conditioning the constant relative humidity, generally WVP rises following the increment of temperature, whose percentage of augment is same as water’s saturated vapor pressure.

5.The silica gel shall be screened before drying to get rid of small particles and dust. If drying temperature of 125℃ doesn’t lower the absorbing ability, the drying temperature is not raised significantly. Air circulation Inside the drying oven is not needed using a fan, but it can’t be sealed, enabling the air inside the oven to be exchangeable with the outside air continuously. Silica gel can’t be used when temperature is higher than leather specimen, because silica gel will cool slowly in the jar affecting the testing conditions. Silica gel has to be cooled for long time before use.

In addition to this version, we also supply Water Vapour Permeability Test Chamber, which can generate constant temperature to meet test requirement.

If you are looking for specific test standards in PDF, welcome to contact with us.

Amadetech is a professional Leather Testing Instruments and Footwear Testing Machines supplier from China, offering various lab testing equipment with decent quality in competitive price. Please click our product page to learn more If you are interested in it, or directly reach us by sales@amade-tech.com.