Different types of leather have different requirements for thickness. For example, the thickness of general cowhide leather for vamp is 1.2mm-1.5mm, and sheepskin leather for upper is 0.6mm-0.9mm. Determining the leather thickness is also an indispensable step before making determinations of leather tensile strength, leather elongation, tearing strength and bursting strength.

Principle

Because leather is a soft and porous substance, whose thickness is associated with the pressure exerted, thickness has an according reduction when the pressure increases. This phenomenon is more obvious on loose leather, especially for oil-tanned leather. The time for which the pressure is applied to the specimen is inversely proportional to the thickness under a certain pressure. In order to avoid the error resulting from influences of time and pressure, the thickness is read and recorded when the total pressure 393g±10g(equal to 500g/㎡) is exerted on the test specimen lasting for 5 seconds.

Instrument

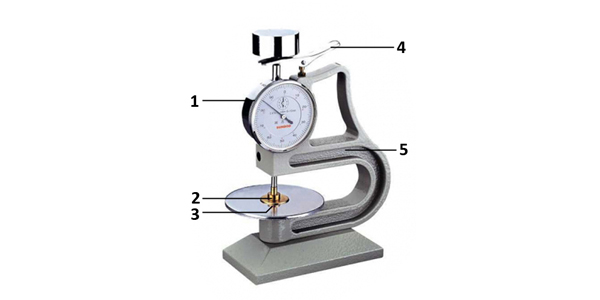

leather thickness gauge

1.Dial gauge: It is a round dial which can indicate the reading to the nearest 0.01mm. There is a pointer getting very close to the scale, to reduce the parallax error to the minimum.

2.Presser foot: Its diameter is 10mm, a cylinder in the same middle axle with the anvil, capable of moving vertically relative to sample testing platform. Presser foot is parallel to the anvil. The parallelism error of anvil at any positions is not more than 0.005mm. The prescribed load applied to the anvil is 393g±10g(equal to 500g/㎡).

3.Anvil(Testing platform): Its a flat horizontal cylinder whose diameter is 10mm, 3cm in height protruded above the surface of a concentric flat circular platform with 50mm in diameter. The platform of diameter 50mm is used to support the weight of leather with medium mass to avoid a convex occurring at the position of presser foot, so that it helps in averting a train of errors.

4.Handle

5.Stand

Sample Preparation

1.For the specimen sampled in light of prescription, the thickness of 5 points arranged in the shape of a cross is measured.

2.For the specimen prepared for other tests, the thickness of 3 points arranged in-line shape is measured.

3.For the specimen has unknown origin, the thickness of 5 points arranged in the shape of a cross is measured.

4.For the rigid leather, small piece of sampling is recommended to avert bending, the thickness of 3 points arranged in-line shape is measured.

5.For whole piece of hide, 5 points for each location shall be measured.

Measuring Method

1.Adjust the pointer of gauge to “zero”.

2.Raise the presser foot with the help of lifting lever.

3.Put the specimen on the testing platform, enabling the grain side to be up.

4.Put down the presser foot slowly, resting on the specimen and noting down the reading after 5s.

Expression of Results

Expressed as the arithmetic mean value, to an accuracy of 0.01mm.

Attention

1.When determining the thickness, operator shall lay down the presser foot slowly and gently. Fierce collision is prohibited, in case of inaccuracy.

2.During the determination, presser foot at any locations shall keep parallel to the testing platform.

3.Apart from rigid leathers of thickness 3mm or more than 3mm, this method is suitable for all leathers tanned in any way.

If you are looking for specific Test Standards in PDF, please contact with us to get them freely.

Amadetech is a professional Leather Testing Machines supplier from China, offering various lab testing equipment with decent quality in competitive price. Please click Leather Thickness Gauge to learn more If you are interested in it, or directly reach us by sales@amade-tech.com.