Horizontal Burning Test (HB)

Overview

The flammability rating of the UL94 Horizontal burning test is HB. It is the lowest flame retardant rating in the UL94 standard. When testing, one end of the sample is clamped and placed horizontally in the test area. The other end of the sample is ignited by an ignition source of specified energy and angle.

If the flame continues to spread, start timing when the flame passes the first reference line on the sample, and stop timing when the flame goes out, provided that the flame does not reach the second reference line. Or stop timing when the flame reaches the second reference line provided that the flame passes the second reference line. The travel distance the flame burns between the two reference lines divided by the corresponding time is the linear burning rate.

Specimen Preparation

Specimen length: 125±5 mm

Specimen width: 13±0.5 mm

Specimen thickness: not more than 13 mm

Specimen quantity: 6 pcs

Specimen Preconditioning

Place the specimens at 23±2°C, (50±5)% RH environment for at least 48 hours.

Test Procedure

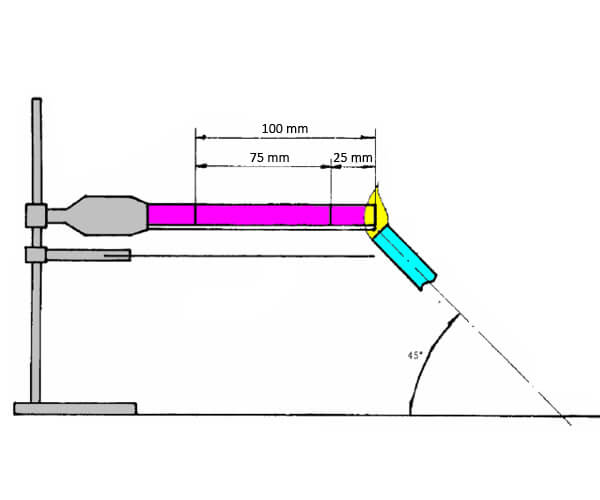

Mark each specimen with 2 reference lines vertical to the longitudinal axis of the bar, 25 mm and 100 mm from the end that is to be ignited.

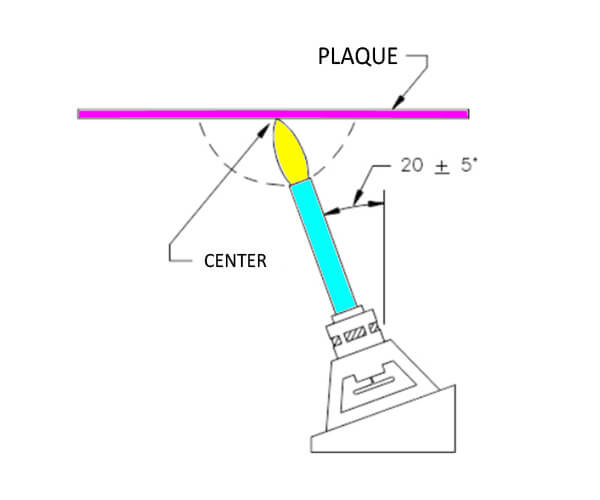

Clamp the specimen at the end farthest from the 25 mm line, with its longitudinal axis horizontal and its transverse axis tilted at 45 degrees. (Refer to the below picture)

Horizontal burning test for HB classification

Ignite the burner and adjust it to produce a blue flame of 20 mm in height, then Incline the burner by 45 degrees towards the specimen to apply the flame to the free end at the lower edge of the specimen for 30 seconds, ensuring the flame impinges on the free end of the specimen to a depth of 6 mm.

As soon as the combustion front of the specimen reaches 25 mm line, start the timing device to record the time “t” in seconds until the combustion front passes the 100 mm line. If the combustion front passes the 25 mm line but doesn’t pass the 100 mm line, record the corresponding elapsed time “t” in seconds and the damaged specimen length “L” in millimeters between the 25 mm line and where the combustion front stops.

Repeat the above steps on the rest 2 specimens, and calculate the linear burning rate “V” based on the below equation:

V=60L/t

Evaluation Criteria for Classification HB

Judging factors involved | ||

Flammability rating | Sample condition | Burning rate |

HB | 3 ~ 13 mm in thickness | ≤ 40 mm per minute over a 75 mm span |

HB | < 3 mm in thickness | ≤ 75 mm per minute over a 75 mm span |

HB | The flame goes out before reaching the 100 mm reference line | |

50 w Horizontal Burning Foamed Material Test ( HBF, HF-1, HF-2)

Overview

This test is used to determine the relative rate of burning and the extent and time of burning of horizontally oriented foamed materials. The specimen of 50 mm by 150 mm is placed horizontally on the wire gauze, and its one end is ignited by a specified burner lasting for 60 seconds. Afterflame time, afterglow time, the time it takes for the flame to pass over a specified span, and damaged specimen length are recorded. According to the test results obtained on the specimens, the materials can be classified into different flammability ratings, including HBF, HF-1, or HF-2.

Specimen Preparation

Specimen length: 150±5 mm

Specimen width: 50±1 mm

Specimen thickness: not more than 13 mm

Specimen quantity: 20 pcs

Specimen Preconditioning

Place 2 sets of 5 specimens at 23±2°C, (50±5)% RH environment for at least 48 hours.

Place 2 sets of 5 specimens in an air-circulating oven at 70±1°C for 168 h, and then place them in a desiccator for at least 4 h to cool down to room temperature.

Test Procedure

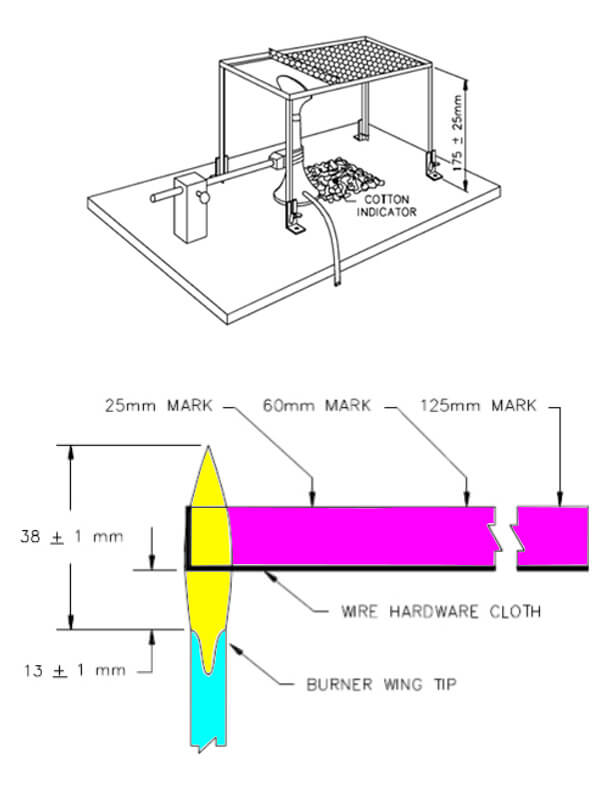

Position the specimen wire cloth flat in such a way that 13 mm above the tip of the burner wing tip and 175 mm above the surgical cotton of specified dimensions.

Mark each specimen over the width with three lines 25 mm, 60 mm, and 125 mm from one end, then place the specimen flat on the wire cloth allowing the end close to the 25 mm line to be the starting point of the flame application.

Ignite the burner and adjust it to provide a 38 mm high blue flame, then position it to allow one edge of the flame to align with the upturned end of the wire gauze, and the other edge of the flame extends into the front end of the specimen.

Horizontal burning test for HBF, HF-1 or HF-2 classification

Apply the test flame to the specimen for 60 seconds, immediately start timing upon the removal, then start another timing device when the flame reaches the 25 mm line to record the corresponding times and burned length of the specimen and calculate the required test results based on specified requirements.

Whether or not the dry cotton below the specimen was ignited by flaming particles is visually observed during the burning test.

Repeat the above steps for other specimens.

Evaluation Criteria for Classification HBF, HF-1 or HF-2

Flammability rating | Judging factors involved |

HBF | Not have any specimens with a burning rate more than 40 mm per minute over a 100 mm span |

HBF | Have each specimen stops to burn before flaming or glowing reaches the 125 mm line |

Judging factors involved | ||||

Flammability rating | Afterflame time | Afterflow time for each individual specimen | Whether the cotton underneath the specimen was ignited | Damaged length for each individual specimen |

HF-1 | 4 out of a set of 5 specimens not more than 2 s, and 1 out of a set of 5 specimens not more than 10 s | ≤ 30 s | No | < 60 mm |

HF-2 | Yes | |||

50 w 20 mm Vertical Burning Test (V-0, V-1, V-2)

Overview

The 20 mm vertical burning test is one of the most commonly used flammability tests. The bar specimen is required to be positioned vertically and exposed to a test flame of specified height for two 10 seconds. The afterflame time is recorded after the first flame application, and the afterflame and afterglow times are recorded after the second flame application. Whether or not flaming particles drip from the specimen to ignite the cotton indicator needs to be observed and recorded.

Specimen Preparation

Specimen length: 125±5 mm

Specimen width: 13±0.5 mm

Specimen thickness: not more than 13 mm

Specimen quantity: 20 pcs

Specimen Preconditioning

Place 2 sets of 5 specimens at 23±2°C, (50±5)% RH environment for at least 48 hours.

Place 2 sets of 5 specimens in an air-circulating oven at 70±1°C for 168 h, and then place them in a desiccator for at least 4 h to cool down to room temperature.

Test Procedure

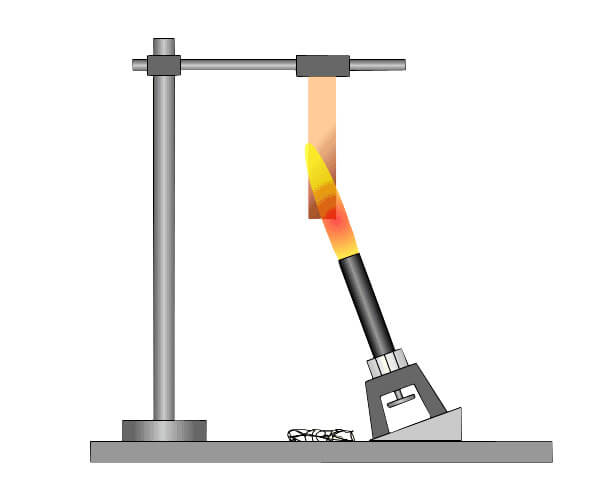

Mount the bar specimen in the holding device to ensure the longitudinal axis is vertical.

Ignite the burner away from the specimen, and adjust it to produce a blue flame of 20 mm in height.

Move the unlit burner to the test position, then tilt it by 45° toward the specimen. Adjust the spacing between the top of the burner and the lower end of the specimen to 10 mm. A metal gauge is required to facilitate this operation.

Ignite the burner again and apply the flame centrally to the middle point of the bottom edge of the specimen for 10 seconds. Remove the flame once the time is up, and immediately record the afterflame time (t1) in seconds.

Vertical burning test for V-0, V-1 or V-2 classification

As soon as afterflaming of the specimen ceases, immediately replace the burner in such a way that 10 mm under the remaining portion of the specimen for an additional 10 seconds. Immediately record the second afterflame time (t2) and afterglow time (t3) in seconds once the flame application is over.

Inspect and record whether or not specimens drip flaming particles that ignite the cotton indicator.

Repeat the above steps for other specimens.

Evaluation Criteria for Classificaton V-0, V-1 and V-2

Flammability rating | V-0 | V-1 | V-2 | |

Judging factors involved | Afterflame time for each individual specimen of a set of 5: t1 or t2 | ≤ 10 seconds | ≤ 30 seconds | ≤ 30 seconds |

Total afterflame time for a set (t1 + t2 for 5 specimens) | ≤ 50 seconds | ≤ 250 seconds | ≤ 250 seconds | |

Afterflame plus afterglow time for each individual specimen after the second flame application (t2 + t3) | ≤ 30 seconds | ≤ 60 seconds | ≤ 60 seconds | |

Whether the afterflame or afterglow reached the clamping device | No | No | No | |

Whether the cotton indicator was ignited by flaming particles or drops | No | No | Yes |

500 w (125 mm) Vertical Burning Test (5VA, 5VB)

Overview

The 500 w (125 mm) burning test is the most stringent vertical combustion test in UL94 and has the highest requirement for the flame retardancy characteristic of the sample. It requires a 500 w burner to produce a flame height 125 mm high. Bar specimens and plaque specimens are subjected to the test flame for five 5-second flame applications. The afterflame plus afterglow time for the bar specimens is recorded after the removal of the fifth flame application. Information is recorded on whether or not flaming material drips from the specimens and whether or not the plaque specimens exhibit burn-through.

Specimen Preparation

Bar specimens

Specimen length: 125±5 mm

Specimen width: 13±0.5 mm

Specimen thickness: not more than 13 mm

Specimen quantity: 20 pcs

Plaque specimens

Specimen length: 150±5 mm

Specimen width: 150±5 mm

Specimen thickness: not more than 13 mm

Specimen quantity: 6 pcs

Specimen Preconditioning

Place 2 sets of 5 bar specimens and 3 plaque specimens at 23±2°C, (50±5)% RH environment for at least 48 hours.

Place 2 sets of 5 bar specimens and 3 plaque specimens in an air-circulating oven at 70±1°C for 168 h, and then place them in a desiccator for at least 4 h to cool down to room temperature.

Test Procedure

Test Procedure for Bar Specimens

Clamp the specimen from the upper 6 mm of the specimen, with the longitudinal axis vertical, so that the lower end of the specimen is 300 mm above the absorbent cotton.

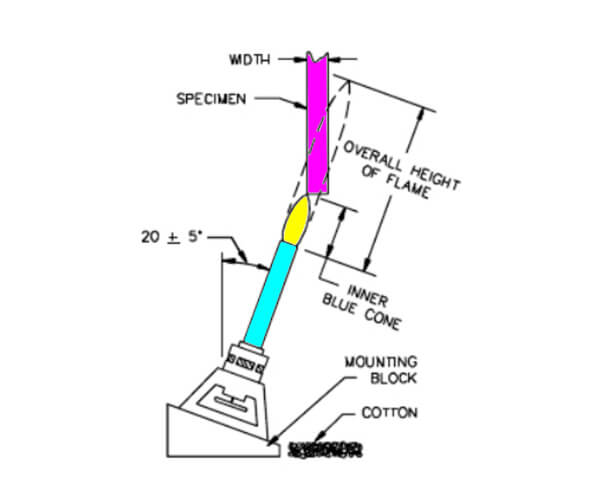

Ignite the burner in a vertical position remote from the specimen and adjust the gas flow to allow it to produce a flame 125 mm in overall height, with 40 mm of the inner blue cone.

Move and incline the burner to allow the burner tube to be positioned at 20±5 degrees from the vertical, ensuring the narrow edge of the specimen is to face the burner.

Vertical burning test for 5VA, 5VB classification – bar specimens

Apply the flame for 5 seconds and then remove for 5 seconds. Repeat the operation until up to 5 applications of the test flame. Ensure the tip of the inner blue cone is in contact with the major portion remaining on the specimen corner when in each flame application.

After the fifth application for each specimen, record the afterflame time, afterglow time and observe whether flaming particles ignited the cotton.

Test Procedure for Bar Specimens

Position the plaque specimen horizontally by means of a corresponding device.

Apply the flame to the center of the bottom surface of the plaque at an angle of 20 degrees from the vertical so that the tip of the blue cone just touches the specimen.

Vertical burning test for 5VA, 5VB classification – plaque specimens

Apply the flame for 5 seconds and then remove for 5 seconds. Repeat the operation until up to 5 applications of the test flame. A means can be taken to ensure the inner blue cone maintains contact with the surface of the plaque in each flame application.

After the fifth application of the test flame, and after all flaming or glowing combustion has ceased, observe and record whether or not the flame penetrated the plaque material.

Evaluation Criteria for Classificaton 5VA, 5VB

Judging factors involved | |||

Flammability rating | Afterflame time plus afterglow time after fifth flame application for each individual bar specimen | Whether cotton incator was ignited by flaming particles or drops from any bar specimen | Whether the flame penetrated (burned through) any plaque specimen |

94-5VA | ≤ 60 seconds | No | No |

94-5VB | ≤ 60 seconds | No | Yes |

Thin Material Vertical Burning Test (VTM-0, VTM-1, VTM-2)

Overview

This test is intended to determine the burning behavior of thin and relatively flexible plastic specimens which are not suitable for using the test of 20 mm vertical burning test (V-0, V-1, or V-2) , by exposing them to a low-energy-level flame ignition source.

Before the test, a sheet of specimen is required to be wrapped longitudinally around a mandrel to form a cylindrical form. The lower end of the cylindrical specimen is subjected to a 20 mm test flame for two 3-second flame applications. The afterflame time is recorded after the first flame application, and the afterflame and afterglow times are recorded after the second flame application. Whether or not flaming material drips from the specimens also needs to be inspected and recorded.

Specimen Preparation

Specimen length: 200±5 mm

Specimen width: 50±1 mm

Specimen quantity: 20 pcs

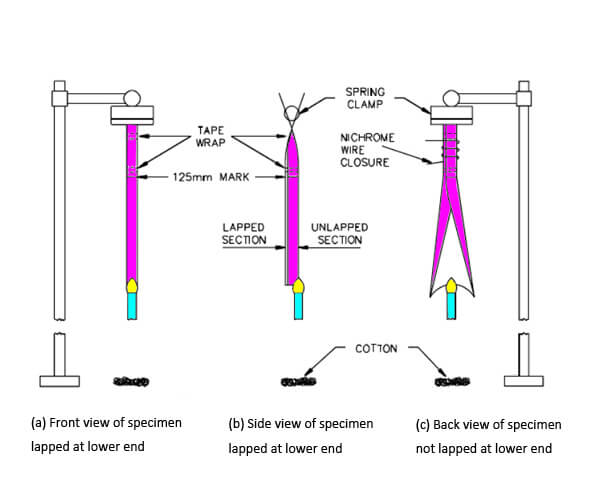

Mark a line across the specimen width 125 mm from one end, then wrap the longitudinal axis of the sheet specimen tightly around the longitudinal axis of a 13 mm diameter mandrel to form a lapped cylinder 200 mm long with the 125 mm line exposed. The overlapped ends of the specimen are to be secured within the 75 mm portion above the 125 mm line by means of pressure-sensitive tape. Finally, remove the mandrel from the sample.

Specimen Preconditioning

Place 2 sets of 5 specimens at 23±2°C, (50±5)% RH environment for at least 48 hours.

Place 2 sets of 5 specimens in an air-circulating oven at 70±1°C for 168 h, and then place them in a desiccator for at least 4 h to cool down to room temperature.

Test Procedure

Clamp the cylindrical specimen from the upper 6 mm of its length with the longitudinal axis vertical, ensuring the upper end of the tube is clogged, and place cotton beneath the specimen.

Ignite the burner and adjust it to produce a blue flame 20mm high.

Tilt the burner at an angle of 45 degrees, then apply the flame centrally to the middle point of the bottom edge of the unlapped specimen so that the top of the burner is 10 mm below the lower end of the specimen, and maintain it at that distance for 3 seconds.

Vertical burning test for VTM-0, VTM-1 or VTM-2 classification

Immediately withdraw the burner and simultaneously record the afterflame time (t1) in seconds.

Once afterflaming of the specimen ceases, immediately replace the burner to apply the flame again to the specimen for 3 seconds. After the flame application time is up, record the afterflame time (t2) and afterglow time (t3) in seconds of the specimen.

Whether or not specimens burn up to the 125 mm mark and whether or not the specimen drips flaming particles igniting the cotton indicator are required to be observed and recorded.

Repeat the above steps for other specimens.

Evaluation Criteria for Classification VTM-0, VTM-1 or VTM-2

Flammability rating | VTM-0 | VTM-1 | VTM-2 | |

Judging factors involved | Afterflame time for each individual specimen of a set of 5: t1 or t2 | ≤ 10 seconds | ≤ 30 seconds | ≤ 30 seconds |

Total afterflame time for a set (t1 + t2 for 5 specimens) | ≤ 50 seconds | ≤ 250 seconds | ≤ 250 seconds | |

Afterflame plus afterglow time for each individual specimen after the second flame application (t2 + t3) | ≤ 30 seconds | ≤ 60 seconds | ≤ 60 seconds | |

Whether the afterflame or afterglow of any specimen reached the 125 mm mark | No | No | No | |

Whether the cotton indicator was ignited by flaming particles or drops | No | No | Yes |

Where to Get UL94 Horizontal & Vertical Burning Test Equipment?

AmadeTech is a professional supplier of UL94 flammability test equipment. Our machines comply with the relative standard and have excellent performance and cost advantage. For our standard model, one chamber can be compatible with performing different test items by changing different holding clamps. In addition, we can integrate different components into one piece of equipment and increase the test space if required. We always stick to providing the solution suiting customers’ needs.

If you have any questions on the UL94 horizontal and vertical burning test or testing equipment, please feel free to get in touch with Amade Technology.