What is the Folding Endurance Test?

The fold endurance test is a test practice to determine the durability of materials when repeatedly folded under a constant load. The test result is judged by how many times a material can be folded until it breaks, so the folding endurance is indicated by the number of double folds. The more folds the sample can withstand, the better the folding resistance. If, on the contrary, the poor the folding resistance.

What Sample Are Suitable for the Folding Endurance Test?

Paper

Copper foils

Plastic films

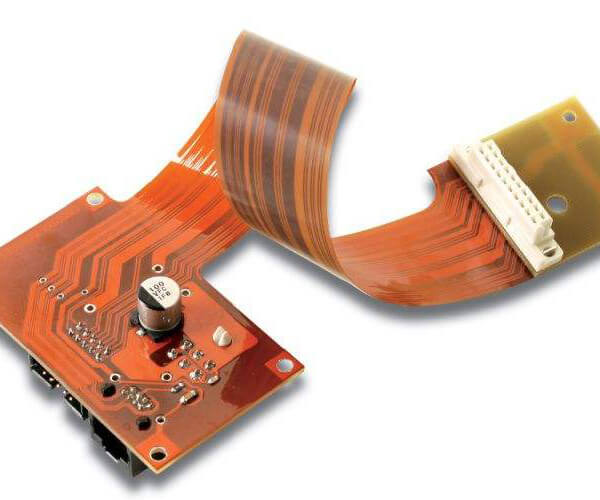

FPC

The samples suitable for the folding Endurance test generally have two characteristics: First, the thickness should not be too thick, and it is generally a relatively thin sheet material. The second is that the material itself must be flexible and not too hard. Specifically, in the actual test, we generally do the folding resistance test on the following samples:

- Papers: including kraft paper, coated paper, newsprint, writing paper, etc.

- Board

- plastic films

- copper foils

- FPC (Flexible printed Circuit Boards)

What Devices Are Used for the Folding Endurance Test?

When we talk about folding endurance testers, the device that comes to mind reflexively is the MIT folding endurance tester, which is used for the folding endurance test of paper in a thickness between 0.25 mm and 1.25 mm.

It is the most commonly used instrument for a paper folding endurance test, such as paper currency, archival paper, reusable paper, test paper, etc. Folding resistance is one of the very important indicators for judging whether the paper is durable. In addition, It can test on aluminum foils and plastic films.

The Schopper-type Folding Endurance tester is another machine used for the folding endurance test of paper less than or equal to 0.25 mm. Its operation method is different from the folding method of the MIT folding endurance tester.

A specimen measuring 100 mm by 15 mm within the specified thickness range is clamped in the left and right retractable jaws. When the machine is actuated, the folding action on the specimen under a specified tension is performed repetitively until the specimen fracture occurs.

The FPC folding endurance tester is specially designed for testing the folding endurance of flexible printed circuit boards. Its outline structure is similar to the MIT folding endurance test machine, and the angle of folding backwards and forwards is also adjustable to suit specific requirements, but the radius of curvature of the rotatable folding surface is different.

Compared with the MIT tester, the distinctive feature of the FPC folding endurance tester is that it has an additional function of conductive detection for samples. Two wires connect the flexible printed circuit board sample and the control system during the folding process. When the FPC folds at break, the controller can detect and stop the folding action automatically.

What Test Standards Need to be Referred in the Folding Endurance Test?

When conducting the folding endurance test with the MIT type folding endurance tester, the commonly referred standards are as below:

- TAPPI-T511

- ASTM-D2176

- JIS-P8115

- GB/T2679-5

- ISO 5626 (MIT & Schopper types)

For the Schopper-type folding endurance tester, the test standards are as follows:

- TAPPI T 423

- SCAN P 17:77

For the FPC folding endurance tester, the following test standards are normally used:

- IEC 249-1

- IEC 326-2

- JIS C5016

- IPC-5016-SS

- JIS C6471

What’s the Principle of the Folding Endurance Test?

A sheet specimen in accordance with the specific specification is mounted in clamping devices. The machine is started to fold the specimen at a specified angle and with a constant load until a fracture occurs. The number of folds is recorded and used to determine the folding endurance and strength of the specimen.

Why Is It Important to Conduct the Paper & Board Folding Endurance Test?

Folding endurance is an important indicator of the physical properties of some sheet materials, including paper and paperboard. The paper folding strength depends on the length, strength, flexibility, and bonding force of the fiber used for papermaking. It directly reflects the application performance and aging resistance of the finished product. For example, the banknotes we use daily are repeatedly folded intentionally or unintentionally by different users during storage and use. If their folding resistance is not good, their writing will become blurred or even broken during the folding process, which will affect the normal circulation of currency and adversely impact national economic security. Therefore, the poor folding endurance of banknotes is absolutely unacceptable. A banknote manufacturer must carry on the most stringent test on its folding endurance when selecting materials. Only by passing the test can it be allowed to leave the factory and be released.

The paper and board suitable for corrugated cardboard boxes commonly used in our life also are required to withstand reciprocating folding without breaking easily. After the corrugated box is formed, the indented parts of the box body and the flap need to be bent. The four indentation lines of the box body are generally parallel to the direction of corrugation. When nailing the box, it should be bent 90° or even 180° toward the concave surface of the indentation. The indentation line of the flap is perpendicular to the corrugated direction, and the concave and convex surfaces of the indentation will be bent many times during use (the maximum angle reaches 270°), which is easy to cause damage to the carton. These special parts have higher requirements on the folding resistance of the materials. Performing the folding endurance test on these materials is necessary to ensure product quality.

In addition, tracing paper, writing paper, letterpress printing paper, book cover paper, wrapping paper, and other cultural printing papers also need to be tested for folding resistance. Otherwise, it is easy to cause the printed text and pictures to become blurred and affect people’s perceptions.

The above examples all illustrate the importance of the paper & board folding endurance test. The folding endurance test can help you accurately judge whether the selected material is suitable, whether the manufacturing process meets the standard, and whether the final product can meet the requirements in the laboratory. This test can help you save R&D and manufacturing costs and improve market competitiveness. In a word, the folding test is an essential test item in the papermaking & packaging industry and product quality inspection laboratory.

Conclusion

The above are some things you need to know about the paper & board folding endurance test. It may not be very comprehensive. Welcome to add and discuss if there is more content.

If you are looking for folding test machines, welcome to contact us. AMADETECH is a professional testing equipment supplier. We can provide different types of folding endurance testers to assist your testing needs and customize them according to your requirements. Competitive prices and high-quality products are our specialties. Hope AMADETECH’s one-stop solution can play a role in your research and development process.