In the shoemaking industry, the usual instruments that we use to determine the flex resistance of materials include Bally leather flexing tester, Ross flexing tester, vamp flexing tester, outsole flexing tester, finished shoe flexing tester, and so on. Today we will introduce a machine used for cold flexing tests on finished shoes and shoe materials consisting of leather and rubber – Cold Capable Footwear Flexing Tester, generally shortened to Cold Flex Tester.

What’s the Cold capable Footwear Flex Tester?

Cold Capable Footwear Flex Tester is an instrument that simulates the low-temperature environment of nature in the laboratory for a specified number of flexing tests on specimens mounted in various clamps.

It is specifically used to determine the cold resistance of rubber, leather, shoe materials, finished shoes, etc., to understand the ability of materials or finished products to adapt to low-temperature climates or cold regions.

The cold flex tester is also referred to as the low-temperature flexing test chamber.

Unlike ordinary footwear flexing test equipment, the cold flex tester features a cabninet to accommodate different clamps and fixtures.

Before the test, you are allowed to set the temperature to a specified value in consistant with the requirement of the test standard.

When the specimen is continuously bent, the temperature inside the chamber can be maintained at the desired constant temperature.

What Types of the Cold Flex Test Chambers Are Available?

Horizontal-type Cold Flex Test Chamber

The shape of the horizontal type test chamber is a cuboid freezer, It has an up-turning door, and you need to pull it from the top surface when you open it. All the space in the inner box can be fully utilized.

Compared with the vertical test box, the horizontal type can be more convenient to install and remove the sample.

Its disadvantage is that it occupies a larger space.

Horizontal-type Cold Flex Test Chamber

Vertical-type Cold Flex Test Chamber

Vertical-type Cold Flex Test Chamber

The shape of the vertical type test chamber is similar to most refrigerators in our homes.

It uses a side door and occupies a small space. Its cost is lower than that of a horizontal test box.

The vertical type is the type adopted by the mainstream cold bending test chamber on the market.

Whether horizontal or vertical, both types of cold flex tester can achieve different flexing test functions with various clamps and fixtures.

What’s the General Techinical specifications of the Cold flex tester?

| Model | AT-F3001 |

| Test temperature Range | RT ~ -10°C, RT ~ -20°C, RT ~ -30°C, RT ~ -50°C, or specified |

| Temperature Uniformity | ±2°C |

| Temperature Accuracy | ±0.5°C |

| Temperature Resolution | 0.01°C |

| Control Mode | PLC + 7 Inch touch screen |

| Flexing Test Apparatus | Specified as following:

1. Bally Flexing clamps 2. Ross flexing clamps 3. Whole shoes flexing clamps 4. Vamp flexing clamps 5. Sole flexing clamps 6. Safety shoe cold Insulation test apparatus 7. DIN 53359 Imitation leather and similar sheet material flexing cracking test 8. Other non-standard test apparatus |

| Power Supply | 1 phase, AC 220V ± 10% or Specified |

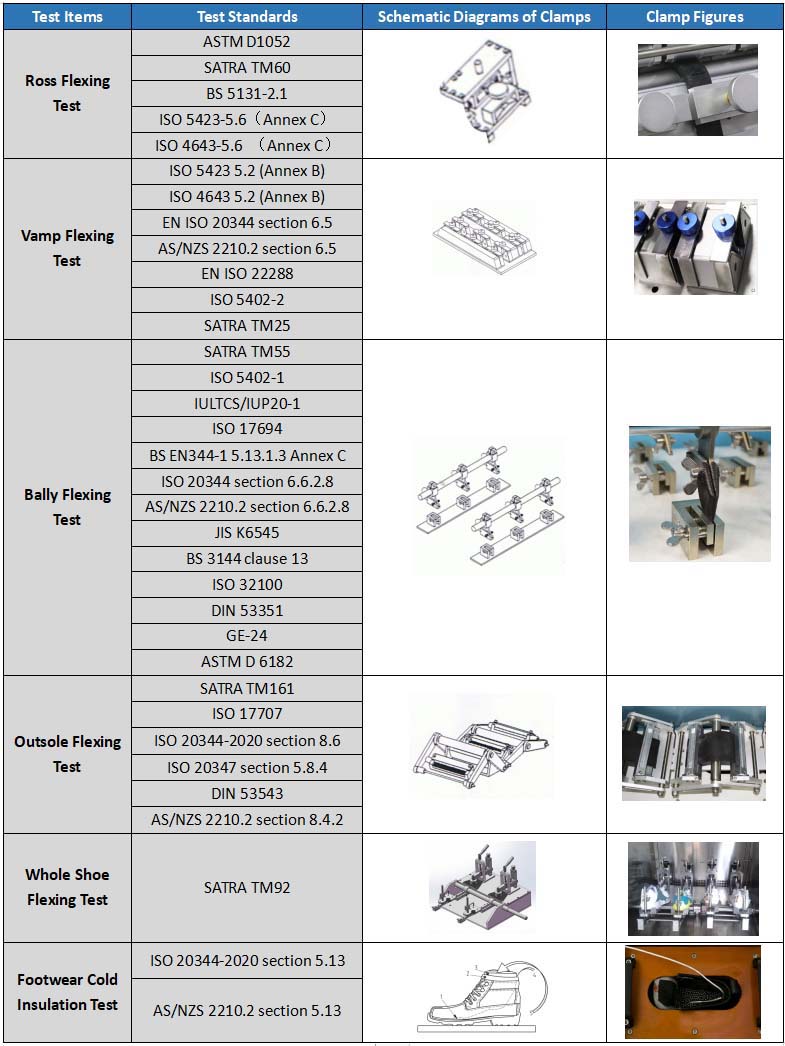

What Are Test Items, Clamps and Test Standards of the Footwear Cold Flex Tester?

Cold Ross Flexing Test

The cold Ross flexing test is used to determine the resistance of rubber soling materials to flexing at low-temperature ambient.

You clamp the test specimen into the machine, ensuring that the notch made in the specimen with a chisel is at the center point of the arc of the mandrel.

After starting the machine, A pierced strip specimen is repeatedly bent freely over a 10 mm diameter mandrel through a 90° angle. You need to measure the cut length at frequent intervals to determine the cut growth rate.

Cold Vamp Flexing Test

The cold vamp flexing test is used to determine the resistance of various upper materials to flexing at low-temperature ambient.

The apparatus is made up of a few pairs of V-shaped clamps with an angle of 40°. Each pair consists of a static clamp and a moving clamp. Their axes are in the same straight line.

The moving clamp is able to reciprocate at a frequency of 5 Hz ± 0.5 Hz under normal conditions and at a frequency of 1.5 Hz ± 0.2 Hz when low-temperature testing is at -5℃.

For routine tests, the distance between each pair of clamps in the open positions is 28.5 mm ± 2.5 mm, and the distance between each pair of clamps in the closed positions is 9.5 mm ± 1 mm.

Cold Bally Flexing Test

The cold bally flexing test is used to determine the resistance of the leather and finishes applied to the leather to flexing at low-temperature ambient.

The apparatus consists of pairs of clamps. You can customize its quantity. Each pair contains an upper moveable clamp and a lower fixed clamp.

The specimen mounting is easy. First, you need to fold the test specimen in 2 with the surface to be tested inwards and fastened in an upper moveable clamp, then you draw the free corners of the specimen outward and downward around the upper clamp to bring the inner surfaces together and clamp the free end in the lower fixed clamp, keeping the lower part of the specimen vertical to the horizontal plane and just taut.

After starting the machine, the upper clamps is capable of moving back and forth through an angle of 22.5° at a frequency of 100 cpm ± 5 cpm.

The instrument will stop automatically once the predetermined number of flex cycles has been reached. You have to examine and record any damage in the flexed area at regular intervals.

Cold Outsole Flexing Test

The cold outsole flexing test is used to determine the flex resistance of outsoles at low-temperature ambient.

The device features a mandrel of 30 mm in diameter. The outsole specimen is flexed around it. You have to ensure that the flexing line is aligned with the axis of the mandrel when mounting the specimen into the machine. You make a cut at the center of the flexing line on the specimen with a chisel.

The outsole specimen will be flexed at a constant rate between 135 cycles per minute and 150 cycles per minute through an angle of 90° about the axis of the mandrel.

You measure the lengths of the cut in the specimen in its fully flexed position before and after the flex using the measuring device, then calculate the amount of the cut growth.

Cold Shoe Flexing Test

The cold shoe flexing test is used to determine the resistance of completed footwear to repeated flexing at low-temperature ambient.

It is applicable to all types of footwear.

Before mounting the specimen, you are required to find the flexing line of the footwear according to the method specified in the SATRA TM92.

During flexing, the footwear specimen is flexed about its flexing line at a rate of 140±10 cycles per minute through a specified angle. Either the number of flexes or the duration of the test can be recorded.

You need to inspect the specimen for any sign of damage, assess and record certain types of damage at number of suitable intervals throughout the test.

You complete the test when either the shoe has failed or it has been suffered from a total of 500,000 flexing cycles. It has taken approximately 59.5 hours for a flexing speed of 140 cycles per minute.

Footwear Cold Insulation Test

The cold insulation test is used to determine the insulation of protective footwear against cold at low temperatures.

Before the test, you are required to condition the prepared specimen for at least 3 hours until its temperature is constant at (23 ± 2)°C, then adjust the temperature of this test chamber to (-17±2)°C and keep it constant.

You place the shoe specimen on the support plate inside the cabinet and use the temperature measuring device connected to the temperature probe to measure the temperature on the insole and insock after 30 more minutes.

The temperature decrease measured during the 30 minute period of cooling needs to be reported.

Non-standard Cold Flexing Test

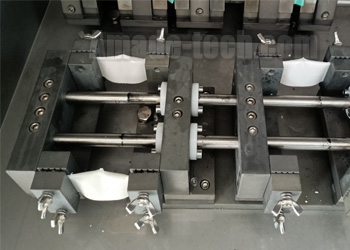

If you want to customize a non-standard test fixture to be installed in this refrigerating cabinet, it can also be fully supported here. Please refer to the picture beside.

Please tell us your detailed test requirements, including important parameters, drawings, test procedures, and other information. Our technical staff will further communicate the engineering details of the apparatus with you and then develop a schematic diagram for your review based on your testing requirements.

If our design can meet your test goals, then we will produce the actual product for you.

Customized Clamps

Why Do You Need to Do a Cold Capable Flexing Test on Shoes or Shoe Materials?

When we walk in shoes, you can see that the upper and sole will also bend once accompanied by each step we take.

Therefore, as a manufacturer, the flexing resistance of shoe materials cannot be ignored. Ensuring the good flexing resistance of the shoes is also one of the essential elements for producing high-quality shoes.

For the same shoe material, under different temperature conditions, its flexing resistance is different. Most materials perform well in bending resistance under normal room temperature conditions, but if it is in sub-zero temperature conditions, their flexing resistance may be greatly reduced.

In order to figure out the actual situation in different conditions, we need a flexing resistance test machine that can simulate a low-temperature environment to help us understand and master the flexing resistance of materials and finished products under different temperature conditions in advance in the laboratory.

How Does a Footwear Material Cold Bending Test Chamber Benefit us?

In the material selection stage, our most reliable way is to put different materials in the desired environment simulated by this bending resistance testing machine to test one by one to find out the bending resistance of different shoe materials in low-temperature environments.

According to the test data, we are guided to select the most suitable materials and lay the foundation for producing products that meet the quality requirements.

When the finished product is produced, we also need to use the corresponding fixture to test whether the flexing resistance of the whole shoe meets expectations in the low-temperature environment. If it meets the quality standards, we can put the products on the market with confidence. If it does not meet the quality requirements, we need to find out the reasons and continue to improve until the quality reaches the required standards.

What Are the Obvious Characteristics of the AMADE TECH Cold Flexing Test Chamber?

Flexible Temperature Ranges

The temperature range of the cold flex tester from AMADE TECH is not fixed. Here you can customize and select the corresponding temperature range according to your test requirements.

If your shoes are to be sold in mid-latitude countries or regions, you can choose a test chamber with a minimum temperature of -30 degrees Celsius. This lowest test temperature will be consistent with the actual temperature of your target area, so it can well simulate the temperature of the environment where the shoes are used to achieve the purpose of the test.

However, if your shoes are to be used in high-latitude or high-cold countries or regions, such as Siberia in Russia, the minimum test temperature of -30 degrees Celsius is far from enough. You may need a test chamber with a minimum temperature of -50 degrees Celsius. Only in this way can the operating temperature of the shoes in the target area be objectively reproduced, and the performance of materials and products can be accurately tested.

For test chambers with different temperature extremes, their prices are different. You can only choose the appropriate temperature range according to your test requirements so as to save purchase costs and improve cost performance.

Flexible Apparatus Layouts

On the one hand, for a single type of clamping apparatus, AMADE TECH can place the required quantity of workstations, for example, 2 stations, 3 stations, 4 stations, etc., in the cabinet based on your testing needs. The premise is that the interior cabinet has enough room to accommodate them.

On the other hand, because the shoemaking industry involves many different low-temperature flexing test items, such as low-temperature Bally leather flexing test, Ross flexing test, vamp flexing test, sole flexing test, etc. If each type of test clamp is configured with a separate test cabinet, 4 test cabinets will be required for 4 test items. It is conceivable that your total purchase cost will be huge.

In order to help you reduce your procurement costs sharply, AMADE TECH has pioneered a perfect solution – clamp integration.

We are able to integrate 4 kinds of fixtures into one test cabinet. Each fixture implements its own test function. You can control and operate each fixture individually to perform independent tests or let all fixtures work together simultaneously.

The money you spend on one machine is equivalent to having the functions of 4 machines. It not only saves costs but also greatly improves the efficiency of testing.

Of course, there are not necessarily 4 types of fixtures in a test chamber. You can tell us the different types of fixtures you will use according to your testing needs.

We will do our best to formulate a considerate solution according to your needs and meet your test goals at the best cost.

Flexible Applications

The maximum temperature of this flexing test chamber is 100 degrees Celsius, and its temperature is adjustable. It means that this equipment can perform not only low-temperature bending tests but also high-temperature bending tests.

In addition, this test chamber is also can be used as a constant temperature chamber for conducting other tests on more specimens such as rubber, plastic, metal, electronic components, etc.

How to Get in Touch with AMADE TECH?

AMADE TECH is one professional footwear testing equipment manufacturer and supplier. We can offer high-quality footwear testing instruments at a competitive price.

Not only can we supply standard testing equipment, but we also provide tailored testing machines required.

For the Low-temperature shoe Flexing Test Chamber, we are able to arrange different types of clamping apparatuses in one chamber in accordance with your request to allow you to save much cost.

You could fill out below form to inform us of your testing requirements and request free quotations.

Or directly reach us at sales@amade-tech.com.