UV(ultraviolet) Light Discoloration Tester China Supplier

In our daily life, common sense tells us that white or light-color substances are easy to turn yellow at exposure to ultraviolet irradiation for a long time. In order to predict this phenomenon, people have to figure out a device to determine it.

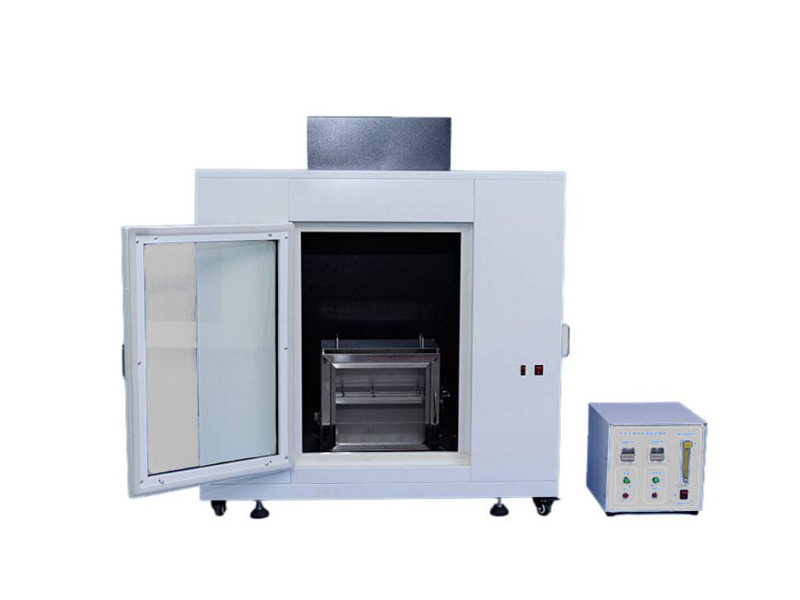

UV Light Yellowing Resistance tester is an environmental test chamber that provides a simulative environment exposed to the radiation of intensive UV(ultraviolet). The test piece is put under UV light. The degree of specimens’ change in color is observed within the defined time to judge the resistance to color fading.

Different from the bulb-type UV light discoloration test chamber, the light source of this testing equipment is configured with 2 pc 15W ultraviolet tubes (wavelength 280nm – 400 nm). Tubes have to be replaced every 500 hours applied. The test temperature, relative humidity and moisture can’t be set during the test.

This tester is mainly used for testing yellow resistance to UV (ultraviolet) of light-color or white fabrics, leathers, PVC, rubbers etc.

Test Standards

- ASTM-D1148-95 Test method of discoloration for footwear

- HG/T 3689 Test method of discoloration for footwear

Main Technical Specifications

| Model | AT-L9004-B |

| Light Source | UV Lamp tube 15W, wavelength: 280 nm ~ 400 nm |

| Sample Shelf | Stainless steel, height adjustable, Statical |

| Lamp Service Time | 500 Hours |

| The Distance Between UV Lamp and Specimen | 150 mm ~ 250 mm |

| Timer | LCD, 0 ~ 999 h |

| Internal Chamber Size | 50 × 30 × 40 cm |

| Machine Overall Dimension | 61 × 34 × 41 cm |

| Weight | 20 kg |

| Power | 1 phase AC 220 V 1 A or specified by customers |

| Accessories | UV lamps 2 pcs (Philips)

Stainless steel shelves 2 pcs |

UV Light Discoloration Testing Machine Operation Procedure(for reference only)

- Check all testing configurations in place and connect to the power source.

- Prepare 4pcs of specimens measuring 30 mm × 10 mm based on HG/T 3689, 3 pcs for testing and 1 pc left for comparison after the test. Please note specimens’ amount and dimension vary in different standards referenced.

- Open the door and put the specimens on the steel rack in the chamber, the sides of test pieces placed toward the UV source. The horizontal plane of the specimen parallel to the lower level of ultraviolet tubes ensures the uniform exposure, whose vertical distance is 250 mm ± 2 mm, causing the lengthwise direction of the specimen to be perpendicular to the direction of tubes.

- Close the door and set the time of exposure by UV irradiance continuously.

- After the testing time specified is over, take out the test pieces to get the result via comparison.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.