AmadeTech provides a wide range of pull testers for measuring pulling forces and compression-resistant values of various materials. They include vertical push-pull testers, horizontal pull testers, hand-operated pull testers, motorized pull testers and so on. By changing different clamps, we can use these pull testers to achieve precise measurement of various samples, and can effectively help users to master the basic mechanical properties of samples.

Pull testers are very suitable for the measurement of simple mechanical strength of materials, such as tensile pull strength, compression force, tearing force, peeling force, penetration force, etc. A pull tester machine is mainly composed of a test stand, a push-pull gauge, and a pair of grips. They are compact, simple in structure and small in size, so compared to traditional Universal Testing Machines, the price of pull test machines is cheaper.

What Is a Pull Tester?

The pull tester is an instrument intended to measure the tensile force values or compressive force values of various cables, crimped terminals, connectors, tapes, caps, buttons, films, springs, sponges, and so on.

It is a versatile testing device. By mounting different fixtures and attachments, it can complete a series of quick-action tensile testing and compression testing. It is widely used in laboratories, production lines or quality inspections in many industries.

What Are the Applications of the Pull Tester?

The main application of the Push pull tester is performing pull testing, for example, the wire terminal pull-off force test, bottle cap pull-off force test, fish hook / line tensile strength test, clothing button pull-off strength test, toothbrush hair bundle pull-off force test, artificial turf pull-out force test, can opening force test, spring tension test, etc.

In addition, the other application of this pull tester is conducting compression testing, like sponge compression test, film piercing force test, spring compression force test, tempered glass membrane breaking force test, etc.

Aside from standard grips and attachments, we can also customize different grips and fixtures for you to achieve different test goals according to your special samples and test requirements.

What Styles of Pull Testers Are Available at AMADE TECH?

Vertical Pull Tester

The main structure of the vertical pull tester is erect, and the height of the machine is much greater than the horizontal length of the base. When the instrument is running, the stroke direction of the fixture is vertically upward or downward.

It is compatible with different gauges and driving systems. Its advantage is that it occupies a small area and can easily perform tensile or compression tests on samples. It is the mainstream structure of the tensile testing machine.

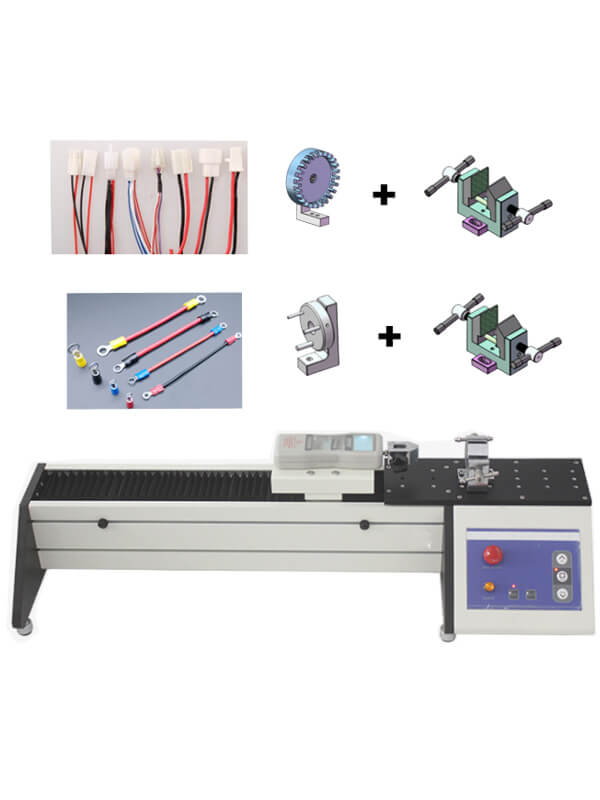

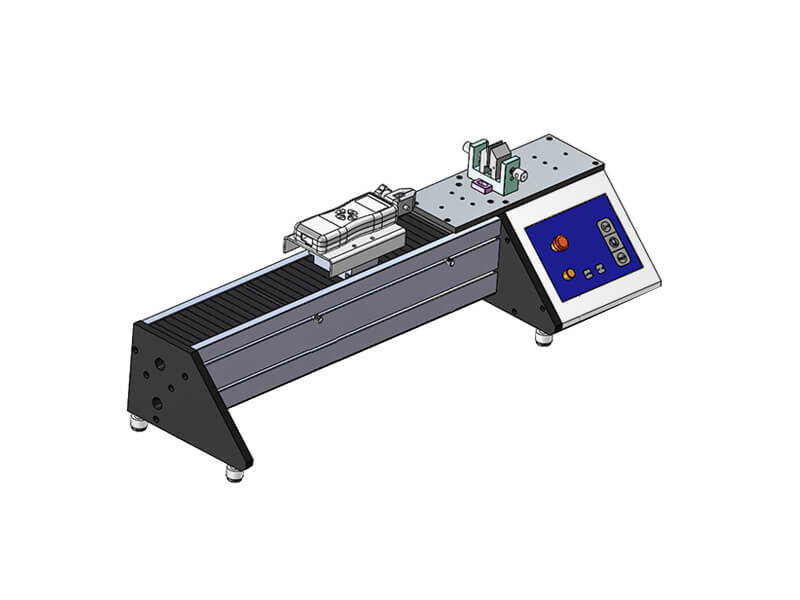

Horizontal Pull Tester

Contrary to the vertical style, the stand of the horizontal pull tester is lying horizontally on the bench. Theoretically, the horizontal pull tester can be designed to have a long test stroke, and the influence of the weight of the sample itself on the test is eliminated during the test.

It can also be equipped with different push-pull meters and different driving devices. The specimen can be mounted and removed easily. During the test, the operator can clearly and conveniently observe the state change of the sample.

Manual Pull Tester

Manual pull testers include lever operated machines and wheel operated machines. Both can exert the force up to 500 N to the specimen.

- Lever Operated Pull Tester

The lever operated machine features a handle to directly work on the movable module. It uses the principle of leverage to help user quick test.

When you hold the end of the handle, you can easily press to drive the connected structure to move back and forth to complete the tensile and compression test. The transmission method of the force is simple, direct and efficient. It is very suitable for wire and terminal pull testing.

- Wheel Operated Pull Tester

The wheel operated machine is configured with a handweel to enable you to turn in clockwise or counter-clockwise direction to drive the movable module.

The mechanical transmission system of the wheel operated machine adopts high-precision ball screws and linear guides, and its rotation gap is extremely small, which greatly improves the precision of the test. During the test, you turn the handwheel to move the fixture up and down or back and forth to achieve a tensile or compression test on the tested product.

Turning the handwheel can control the movement of the moving components very accurately, and the operation is also very easy and labor-saving.

Motorized Pull Tester

The motorized pull tester uses a precision motor as the power source. With the aid of the control software, it can accurately apply force to the specimen at a specified speed and a specified stroke to complete tensile and compression tests.

The motorized pull tester can free your hands during the test. After the sample is clamped, you only need to enter the necessary parameters in advance, and the entire test will be completed automatically.

The electric pull tester uses a ball screw as a force transmission device, which has high efficiency, good stability and low noise. The speed of the test can be controlled by the speed switch. With special software, data can be transferred to a personal computer in real time for display, storage, and printing.

Which Kind of the Push Pull Gauge Is Configured for Our Pull Testers?

A digital push pull force gauge HP is configured for most of our pull testers. It is a multi-functional and high-precision dual-purpose gauge that is specially used to measure push and pull forces. We provide gauges with different measuring ranges and accuracy. You can feel free to choose the appropriate capacity based on the testing requirements.

A high-definition LCD on the front side to present the data and state. A few rows of physical keys are distributed below the display are used to set various parameters. You can set the upper / lower limits of the force value, and the gauge will alarm automatically by audio or flashing indicator on the display once it reaches the limit.

Three test modes Real-time / PEAK / ATUO PEAK modes are available, allowing you to select one of them according to your test needs. In AUTO PEAK mode, you can set the peak hold time from 0 to 9 seconds. The gauge will automatically shut down if it is not in use for a preset period.

There are 30 sets of data that can be stored. It is equipped with professional software and a communication cable to connect to a computer to display real-time data and test results. It is powered by a rechargeable battery or AC power source.

The force gauge has the characteristics of high accuracy, long service life, compact size, long standby time, simple operation, and high-cost performance. It is suitable for push-pull load test, plug-in force test, destructive force test, etc.

HP Digital Force Gauge Options

| Model | HP2 | HP3 | HP5 | HP10 | HP20 | HP30 | HP50 | HP100 | HP200 | HP300 | HP500 | HP1000 |

| Capacity | 2 N | 3 N | 5 N | 10 N | 20 N | 30 N | 50 N | 100 N | 200 N | 300 N | 500 N | 1000 N |

| 0.2 kgf | 0.3 kgf | 0.51 kgf | 1.02 kgf | 2.04 kgf | 3.06 kgf | 5.1 kgf | 10.2 kgf | 20.4 kgf | 30.6 kgf | 51.0 kgf | 102.0 kgf | |

| 0.45 lbf | 0.67 lbf | 1.12 lbf | 2.25 lbf | 4.5 lbf | 6.74 lbf | 11.24 lbf | 22.5 lbf | 45.0 lbf | 67.4 lbf | 112.4 lbf | 224.8 lbf | |

| Resolution | 0.0001N | 0.001 N | 0.01 N | 0.1 N | 1 N | |||||||

| Accuracy | ± 0.5 % | |||||||||||

| Test mode | Track / Peak / Auto peak | |||||||||||

| Unit | N / lbf / gf | Kgf / N / lbf | ||||||||||

| Alarm | Available in upper and lower limits of range / low power | |||||||||||

| Application | Tensile / Compression | |||||||||||

| Sensor | Built-in | |||||||||||

| Power | Built-in rechargeable battery / AC adapter | |||||||||||

What Grips and Fixtures Can I get From AMADE TECH?

We will configure a pair of standard grip based on your specimen and testing requirements, which is free of charge. AMADE TECH can provide different types of clamps for tensile, compression, peeling, bending, tearing, puncture and other tests for customers to choose.

In addition to the standard grips, we can also customize the personalized fixtures for you. These grips and fixtures can be integrated with our pull testers.

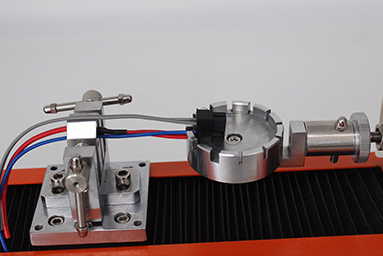

How to Use a Wire Crimp Pull Tester?

The wire crimp pull tester is mainly used to determine the pull-off force of various wire terminals.

It is equipped with a special disc-shaped multi-terminal grip. The wire crimp pull tester is mainly used in cable, electronics, electrical appliances and other industries.

The operation is very simple, the steps are as follows:

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.