Rubber Rheometer | Rotorless Rheometer China Manufacturer

Moving die rheometer is also referred to as the MDR rhometer, which is used to determine the change of the shear modulus of the rubber compound during the vulcanization process. The shear modulus is directly proportional to the crosslink density, so the measurement result reflects the change in the degree of crosslinking of the compound during the vulcanization process, obtaining a curve of the crosslinking speed of the rubber compound at the vulcanization temperature with the change of time to determine the best vulcanization formula.

The rotorless rheometer is the most widely used instrument in the rubber processing industry to control rubber quality, conduct the rapid inspection and perform basic rubber research. It provides accurate data for the optimal rubber formula combination and can accurately measure parameters such as scorch time, positive vulcanization time, vulcanization index, maximum and minimum torque.

Test Principle

The rubber test sample is placed in an almost entirely closed die cavity and keep it at the test temperature. The die cavity consists of the upper die and the lower die. The lower die moves back and forth in a slight linear motion(oscillation), and the oscillation causes the sample to generate the shear strain. The reaction torque of the test piece to the cavity is measured. The magnitude of this reaction torque depends on the shear modulus of the rubber compound.

When the testing begins, the shear modulus of the test sample increases along with the time. The computer displays and records the reaction torque values. When the force rises to the maximum value or a constant value then turns to decline, a curve of reaction torque to time is obtained. The shape of the curve is related to the testing temperature and the characteristics of the rubber compound.

INQUIRE

The Importance of MDR Rheometer

Vulcanization is an important process in the processing of rubber products. In this process, the rubber undergoes a series of complex chemical changes. The rubber changes from a plastic compound rubber to a highly elastic or hard cross-linked rubber, so as to obtain more perfect physical and chemical properties, to improve and broaden the use value and application range of rubber materials. Therefore, vulcanization is of great significance to the manufacture and application of rubber and its products.

The so-called vulcanization means that under heating conditions, the raw rubber in the rubber compound chemically reacts with the vulcanizing agent so that the rubber is cross-linked from linear structure macromolecules into three-dimensional network structure macromolecules. This process is called vulcanization. The process of this cross-linking reaction is completed under certain temperature, time and pressure conditions. These conditions are called vulcanization conditions. In the rubber industry, these vulcanization conditions are indispensable when people make compound formulas, understand the rubber performance and check rubber quality. How to reproduce these conditions in a laboratory? People have to develop an apparatus which can establish these vulcanization conditions of rubber to formulate and verify the required vulcanization formula and get some necessary parameters for regular production. The rubber rheometer can satisfy these needs, and It plays a vital role in the vulcanization process.

Test Standards

ISO6502, ASTM D5289, DIN 53529, GB/T 16584, etc.

Main Technical Parameters

| Model | AT-R7002 |

| Temperature Range | RT ~ 200℃ |

| Minimum Temperature Display | 0.1℃ |

| Temperature Fluctuation Range | ± 0.15℃ |

| Heating Rate | About 15℃ / min |

| Temperature Display Resolution | 0.01℃ |

| Temperature Recovery Time After Clamping | < 1.5 min |

| Temperature Unit | ℃, ℉, |

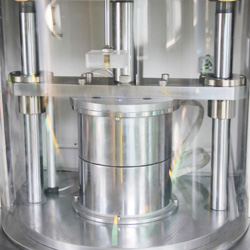

| Die Cavity | Biconical, closed system, sealed |

| Torque Range | 0 ~ 20 N.m |

| Torque Minimum Reading | 0.001 N.m |

| Oscillation Angle | ± 0.5° (Standard), ± 1°, ± 3° |

| Oscillation Speed | 100 r / min (1.67 Hz) |

| Torque Accuracy | 0.3% |

| Torque Unit | Ibf, in, N.m, dN.m, kgf.cm |

| Data Acquisition Rate | 200 Hz |

| Calculated Data | TS1, TS2, T10, T30, T50, T70, T90, VC1, VC2 |

| Software Connection | USB |

| Test Report content printed | Date, time, temperature, vulcanization curve, temperature curve, ML,MH, TS1, TS2, T10, T50, T90, VC1, VC2 |

| Power Supply | 220 V + / – 10% or specified |

| Air Source | Min. 0.6 Mpa |

Rotorless Rheometer Features

- This moving die Rheometer adopts an Alpha closed die cavity made of high precision stainless steel with enough hardness and strength.

- The oscillating die and the static die are sealed by a quality seal ring with a long lifespan to ensure close contact of the edges of the die cavity throughout the test.

- The cavity has a fast heating rate and high-temperature control precision, and the PID control parameters are automatically adjustable in real time.

- This Moving Die Rheometer is equipped with an advanced alpha-based force sensor, whose force precision is up to 0.001N.m.There are the key-press control panel and the touch screen control panel for customers to choose from.

- This machine can be connected to the personal computer with Windows operating system via a USB interface for convenient control, operation and explicit monitoring.

- A professional test software implements temperature control, parameter setting, data acquisition, data analysis, storage and test report output.

- The oscillation system is driven by a Panasonic servo motor working with a servo system, with an oscillation adjuster.

- Grooves are distributed on the top and bottom surface of the cavity to prevent slippage of the specimen.

- Transparent protection enclosure is attached to offer a clear view and safe testing environment for operators, and it supports automatic opening and closing corresponding to the die state.

Applications of Rubber Rheometer

- Control the quality of the rubber compound: Make standard vulcanization curve diagrams of various rubber compounds and reasonably formulate the qualified area of various rubber compounds.

- Identify the raw materials: It can be used in the production department of raw materials in the rubber industry to classify products and evaluate the quality of the products.

- Used for formula research of the rubber compound.

- Calculate the vulcanization temperature coefficient K value and the rubber activation energy E value.

- Calculate the vulcanization effect, vulcanization strength and for further arbitrary conversion of vulcanization conditions.

- Optimize the vulcanization process and conditions: The vulcanization of rubber products is one of the important issues in the rubber process. Correctly master the vulcanization characteristics of the rubber compound to grasp the best vulcanization point, save energy, increase productivity, and obtain the best physical and chemical properties.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.