Plastic Pipe Falling Weight Impact Tester China Manufacturer

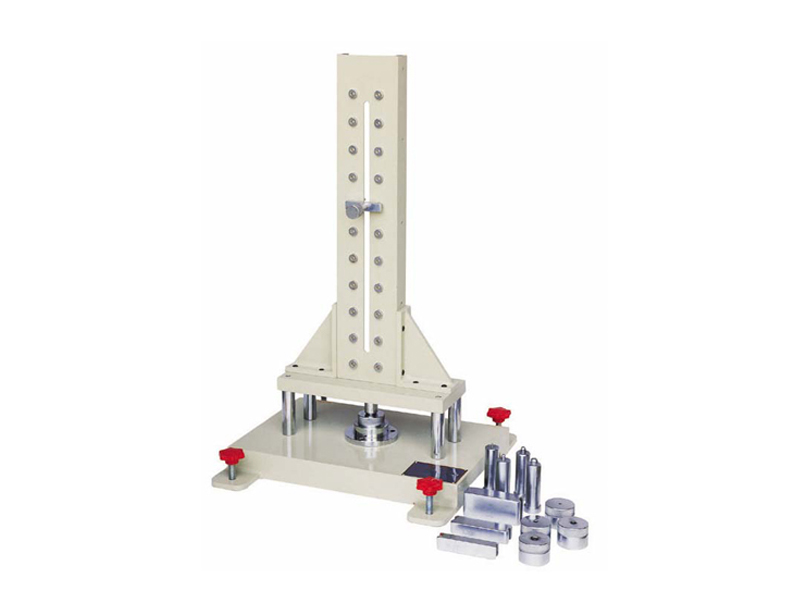

Drop Weight Impact Tester is intended to determine the resistance to external blows of thermoplastic pipes, sheets, fittings, glass, ceramics and other non-metallic materials under specified conditions by means of a falling weight.

The impact resistance of thermoplastic pipe and fittings is an important indicator used to evaluate the suitability for service and quality of processing. The resistance of the material to breakage during handling and installation is also can be reflected via this drop weight test, which helps in establishing impact test requirements in product standards.

The drop weight impact testing machine is applicable to PVC water pipes, PP pipes, PE pipes, drainage pipes, low-pressure feed pipes, core-layer foam pipes, double-wall corrugated pipes, various thermoplastic fittings, etc. Preconditioned specimens with low temperatures are accepted.

This falling weight impact testing machine adopts single-chip microcomputer control and double-tube guide structure. The falling striker has a nose with a hemisphere and combined with a cylinder stem at least 10 mm long. It is hidden inside the guiding tube rigidly fixed in the vertical position to ensure it falls vertically and freely. Type d25 and type d90 noses of the strikers are configured based on the various mass of strikers: Type d25 is for strikers of mass 0.5 kg and 0.8 kg, and type d90 is for strikers of mass equal to or greater than 1 kg. The falling striker can fall from a variable height which can be adjusted to any height up to at least 2 meters.

Test Principle

A falling striker with prescribed mass and shape is lifted to a given height and released to freely blow the specified position around the circumference of the test piece placed on a V-block holder. The test piece is examined by naked eyes for any shatter, crack or split on the inside of the pipe caused by the impact.

Test Standards

ISO 3127

ASTM D2444

ISO 4422

EN 1411

EN 744, etc.

Main Technical Parameters

| Model | AT-P6014 |

| Impact Height | 50 ~ 2,000 mm adjustable |

| Height Error | ± 2 mm |

| Standard Mass of Strikers | 0.25 kg, 0.5 kg, 0.8 kg, 1.0 kg, 1.25 kg, 1.6 kg, 2.0 kg, 2.5 kg, 3.2 kg, 4.0 kg, 5.0 kg, 6.3 kg |

| Optional Mass of Strikers | 8 kg, 10 kg, 12.5 kg, 16 kg |

| Noses of the Striker | d25 & d90, Rs: 50 |

| Specimen Specifications | Φ16 mm ~ Φ400 mm |

| Specimen Support | V-block (2 pcs in different sizes attached) |

| Working environmental temp. | Room Temperature |

| Air supply | 0.6 ~ 0.8 Mpa |

| Power Supply | 220 V, 50 Hz or Specified |

| Dimension | 620 cm × 600 cm × 3386 cm |

Drop Impact Testing Machine Features

- Configured with various interchangeable strikers to meet different testing requirements for impact energy.

- A digital display in English is available for parameter setting and data monitoring.

- Fitted with a quality motor matched with a precision transmission mechanism to lift the falling weight by a constant velocity.

- Equipped with a vertical drop tube coupled with exhaust vent leads to little air friction effect during the falling of weight.

- The lifting height of the impact hammer is adjustable freely, with an auto-calibration function.

- Anti-secondary impact device adopts special air cushion design featuring without noise, lower quiver, long lifespan.

- Automatically hang the hammer, automatically lift hammer to set height position.

- Equipped with two different V-block specimen holders to accommodate various specimens.

- Configured with three-level safety protections: Electric-shock safeguard, tube protection against tup falling accidentally, and door protection to ensure the safety of operators.

- The control box is separated from the drop tube to avoid close contact with the impact equipment during the test.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.