Rubber Compression Set Tester China Supplier

SATRA TM64 Compression Set Test Device with constant force is used to measure the ability of rubber compounds or cellular materials to go back to their original thickness after prolonged action of compressive force. It is able to simulate a state of a specimen being compressed at a specified temperature and for a defined time, allowing you to grasp the resilience of the compressed rubber materials in service life in advance.

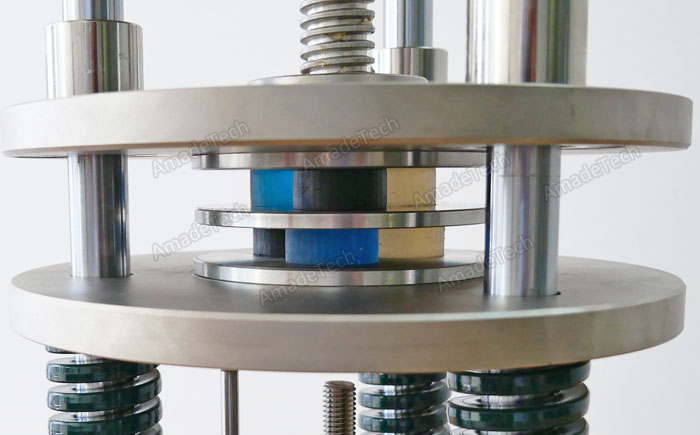

AmadeTech compression set test device is developed in compliance with ASTM D395 Test Method A & SATRA TM64. It has two circular stainless steel plates in the middle to accommodate the sample assemblies. Sample assemblies layered with small stainless steel spacers may contain multiple specimens of the specified size. A handwheel at the top of the device is used to adjust the compressive spacing. The upper platen can move down to approach and apply force to the specimen assemblies placed on the lower plate supported by 3 standing springs as you turn the handwheel clockwise.

A dial gauge is vertically positioned between the device base and the lower plate to measure the real-time spring deflection corresponding to the force the specimen withstands when you exert the downward force by turning the handwheel. The corresponding deflection values consistent with the stress required by related test standards are calibrated and provided in the form of a comparison table by us. It facilitates you to apply a desired force on the specimens conveniently. You are available to adjust the pressure by turning the handwheel freely.

A rubber thickness gauge is required to conduct this compression test, which is available from AmadeTech.

Sandwiched sample assemblies

If you plan to conduct the compression set test following the ASTM D395 Test Method B under constant deflection, the corresponding test apparatus AT-R7020 is also available from AmadeTech.

It features a simple mechanical structure and components consisting of 3 stainless steel plates, 5 threaded rods, spacers, and fasteners. The thickness of the spacer is equal to the required percentage of compression.

Feel free to contact us for more details on this tester if you have interest.

Test Principle

The sample whose thickness has been measured is sandwiched between two stainless steel plates, and a prescribed constant pressure is applied. The entire equipment with the sample is placed at a specified temperature. After the specified condition is met, the thickness of the sample center is measured. The thickness values before and after the test are brought into the corresponding formula to calculate the compression set value.

| Model | AT-R7019 |

| Measuring range of gauge | 0 mm ~ 50 mm |

| Accuracy | 0.01 mm |

| Allowable specimen quantity | 3 ~ 27 pcs |

| Dimensions | 35 cm x 35 cm x 60 cm |

| Weight | 40 kg |

- ASTM D395 Method A

- SATRA TM64

- Made of rugged stainless steel and rigid metal materials.

- Fitted with 3 standard springs with exceptional fatigue-resistant performance.

- Multiple circular spacer plates up to 9 pcs are provided.

- Equipped with a precision gauge to measure the deflection in real-time.

- User-friendly and easy to maintain.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.