It is normal that Leather shoes encounter water when worn, so determination of water resistance of leather subjected to flexing is necessary for product developers and manufacturers. Leather dynamic water penetration tester is used to let the grain surface of test leather in continuously flexed state contact water to evaluate the waterproofness of shoes when worn by people.

The testing projects for waterproofness contain:

a.The flexing time taken for water to penetrate from one side to the other of test piece.

b.Percentage mass of the water absorbed from the beginning of flexing to one or more specified deadlines.

c.The mass of the water transmitted via the test piece within the specified one or more periods.

1. Test Specimen

Size is 75mm*60mm in rectangle, the longer edge is parallel to backbone line.

2.Instrument

1)Cylinders

Pairs of corrosion resistant and insulated cylinders made of rigid material, whose diameter is 30mm, fixed to the 2 axes at the same level. The axes of each pair of clamps are in a straight line. One cylinder is fixed, the other one is driven by an electric motor by a crank, making reciprocating movements along the direction of axles at the speed of 50 cycles per min, with an amplitude of 1.0mm, 1.5mm, 2.0mm or 3.0mm, and the maximum separation of the cylinders is 40mm. The 4 travel ranges result in the shortened distances of 5%, 7.5%, 10% or 15% between 2 cylinders of each pair.

2)Ring-shaped clamps

Used to clamp the longer edges of test piece to the end of cylinders to form a shape of a long trough, whose ends are sealed by cylinders.

3)Water tank

Used to be filled with distilled water in which the test piece is partially immersed.

4)Electrically operated device

Able to release signal automatically once water penetrates the test piece.

5)Absorbent cloth

120mm*40mm in size, 300g/㎡

6)Timing device

7)Balance

Leather Water Penetration Tester

3.The Selection of Amplitude of Backward and Forward Movements

Amplitude and water penetration velocity are different varying with different thicknesses of leather. Instrument has the auxiliary apparatus to choose the flexing amplitude for getting the proper reciprocating amplitude.

①Below parts are included: 2 cylinders in the same axis and ring-shaped clamps to fix the test piece. Turn the crank to let one clamp move closer to the other, moving distance can be observed by gauge. There is a spring attached to the cylinder. Spring is compressed while one spring clamp is moving to the other for shortening the amplitude of flexing, indicating the load value(test should be halted If load is over 120N).

②Operation

a.Separation between cylinders is 40mm, test piece is clamped on the auxiliary device to let one cylinder move 2mm to the other at the speed of 2mm per 5s(equal to shortening 5% of moving part of specimen). repeat the steps and read the load values.

b.Follow above step and just shorten the 10%(4mm) of test piece length, read the value.

③Selection of amplitude: calculate out the mean value based on the data derived from above a & b,

choose 5% amplitude shortened for water penetration test If average value is over 100N.

Choose 7.5% amplitude shortened for water penetration test If average value is 50-100N.

Choose 10% amplitude shortened for water penetration test If average value is more than 20N.

Choose 15% amplitude shortened for water penetration test If average value is less than 20N.

4.Test Procedure

1)Use the Grade P180 abrasive paper to rub against the grain surface of test piece gently(conduct 10 cycles of friction under the load of 9.8N with 100mm travel distance each time).

2)Adjust the machine to the needed amplitude.

3)Weigh the test piece m1.

4)Place the 2 cylinders at the farthest position to each other, and attach the longer edges of test piece to the cylinders with the help of ring clamps, with the same length of test piece(10mm) overlapping each cylinder and with the test piece under sufficient tension to remove folds, grain surface facing outwards, to form a trough, with the shorter edges parallel and at the same level. The moving part of test piece(trough) is equal to the distance between the cylinders.

5)Put the electrical device into the trough.

6)Add the water into tank until the surface lies 10mm below the top of cylinders. Start the machine and note the time t0. Note the time when first time penetration occurs t1.

7)Stop the motor and remove the test piece, bolt gently to remove the adhering water, weigh the test piece m2. put it back and restart the machine.

8)Weigh the dry absorbent cloth m3, roll it to a cylinder with 40mm long and put into the trough with an electrode on the cloth roll. After specified time of motor running, take out the cloth immediately to weigh it m4.

9)If there is no other stipulation, determination of water absorption shall be conducted every 1 hour, and determination of water penetration shall be conducted every 1 hour after penetration occurs.

5.Expression of results

1)Penetration time

t=t1-t0

where

t0 is the time before penetration

T1 is the time after penetration

2)Water absorption

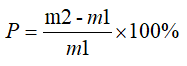

where

P is the water absorption

m1 is the leather mass before penetration

m2 is the leather mass after penetration

3)Water transmission

M=m4-m3

Where

m3 is the mass of dry absorbent cloth

m4 is the mass of absorbent cloth subjected to water transmission for specified time.

If you are looking for Test Standards in PDF, don’t hesitate to contact with us to get what you want.

Amadetech is a professional Leather Testing Equipment supplier from China, offering various lab testing equipment with decent quality in competitive price. Please click our product page to learn more If you are interested in it, or directly reach us by sales@amade-tech.com.